Aluminum Plate Sheets - 5 Bars Plate/Tearplate of Good Quality in Hot Sale!

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

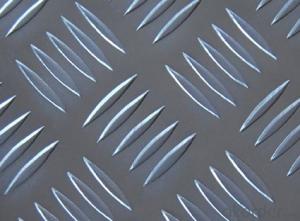

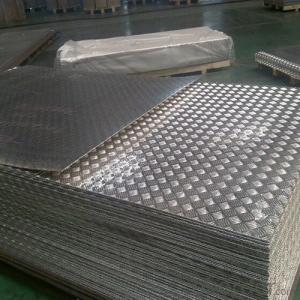

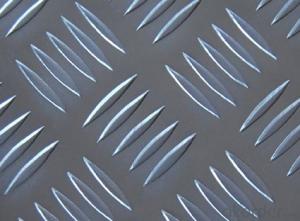

1.Structure of Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale:

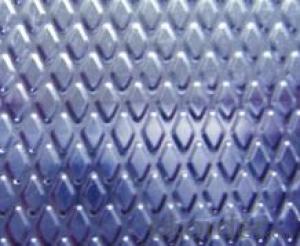

Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Saleis widely used for decorative purposes in construction, packing and appliance. Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Saleis also very commonly used for anti-shippery purposes in vehicles and pulic places.

2.Main Features of Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale:

• Beautiful parten

• Good anti-slippery quanlity

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm-1500mm

4. Production of Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: Can aluminum sheets be used in aerospace industries?

- Yes, aluminum sheets are commonly used in aerospace industries. Aluminum is a lightweight and corrosion-resistant material that possesses excellent strength-to-weight ratio, making it ideal for various aerospace applications. It is used in the construction of aircraft structures, such as wings, fuselage, and landing gear, due to its ability to withstand high stress and pressure. Additionally, aluminum sheets are easily formable and can be fabricated into complex shapes, contributing to the design flexibility required in the aerospace industry. However, it is important to note that aluminum alloys are typically used in aerospace applications rather than pure aluminum, as they offer enhanced mechanical properties and improved performance.

- Q: How do you prevent scratches during transportation of aluminum sheets?

- To minimize the occurrence of scratches when transporting aluminum sheets, there are several steps that can be taken: 1. Adequate packaging: It is important to securely package the aluminum sheets using suitable materials like bubble wrap, foam, or cardboard. This will offer cushioning and protection against external impacts. 2. Application of protective layers: Inserting paper or plastic film between individual sheets will prevent direct contact and minimize the risk of scratching. 3. Secure stacking: When loading the aluminum sheets onto transportation vehicles, ensure they are stacked securely to prevent any movement or shifting during transit. This can be achieved by using appropriate strapping or palletizing techniques. 4. Gentle handling: Properly train personnel involved in the transportation process to handle the aluminum sheets with care. They should avoid dragging or sliding them against rough surfaces that could cause scratches. 5. Avoid contact with sharp objects: Take measures to ensure that the aluminum sheets do not come into contact with sharp objects or edges. This can be accomplished by keeping them separate from other materials or using protective covers. 6. Regular inspections: Regularly inspect the aluminum sheets during transportation to identify any potential scratches or damages. If any are discovered, immediate action should be taken to prevent further harm. By implementing these preventive measures, the likelihood of scratches occurring during the transportation of aluminum sheets can be significantly reduced. This will ensure that the sheets are delivered in optimal condition to their destination.

- Q: Can aluminum sheet be used for food packaging?

- Food packaging can utilize aluminum sheet, which is a popular choice due to its unique properties. This material is lightweight, flexible, and provides excellent protection against moisture, oxygen, and light. Consequently, it helps extend the shelf life of products and maintains their freshness. Aluminum sheet is commonly employed to package beverages, snacks, dairy products, and ready-to-eat meals. Furthermore, it is non-toxic and does not react with food, ensuring safety when in direct contact with consumables. Its versatility allows for easy customization to meet various packaging requirements. Overall, aluminum sheet is widely trusted and used for food packaging due to its durability, protective properties, and adherence to safety standards.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of high-rise buildings?

- <p>Yes, aluminum sheets can be used for exterior walls in high-rise buildings. They are lightweight, durable, and resistant to corrosion, making them suitable for such applications. Aluminum sheets can also be coated or anodized to provide additional protection and aesthetic appeal. They are often used in combination with other materials or as a cladding system to enhance the building's appearance and energy efficiency.</p>

- Q: What are the different methods of heat treating aluminum sheet?

- There are several methods of heat treating aluminum sheet, each with its own purpose and desired outcome. Some of the common methods include: 1. Solution Heat Treatment: This process involves heating the aluminum sheet to a specific temperature, typically between 900-1000°F (480-540°C), and holding it at that temperature for a set amount of time. This helps dissolve any soluble alloying elements present in the aluminum, resulting in a more uniform structure. 2. Quenching: After the solution heat treatment, the aluminum sheet is rapidly cooled by quenching in water, oil, or air. This rapid cooling helps lock in the desired microstructure and properties, such as increased strength and hardness. 3. Aging: Once quenched, the aluminum sheet is subjected to an aging process, which involves heating it to a lower temperature, typically between 250-450°F (120-230°C), and holding it there for a specific duration. This allows for the precipitation of fine particles within the aluminum matrix, improving its strength and hardness even further. 4. Precipitation Hardening: This method is used for certain aluminum alloys, such as 2000 and 7000 series, which respond well to precipitation hardening. It involves a combination of solution heat treatment, quenching, and aging, resulting in a highly strengthened and durable aluminum sheet. 5. Annealing: Annealing is a heat treatment process used to soften the aluminum sheet and relieve any internal stresses. It involves heating the sheet to a specific temperature, usually around 600-700°F (315-370°C), and then slowly cooling it. This helps improve the formability and machinability of the aluminum. 6. Stress Relieving: This method is similar to annealing but is specifically used to reduce residual stresses in the aluminum sheet after fabrication. It involves heating the sheet to a temperature below its annealing temperature and then slowly cooling it. Overall, the choice of heat treatment method for aluminum sheet depends on the desired properties, alloy composition, and intended application. Each method offers distinct advantages and can significantly enhance the mechanical and physical properties of the aluminum sheet.

- Q: What are the safety standards for aluminum sheets utilized in construction?

- <p>Yes, there are safety standards for aluminum sheets used in construction. These standards ensure the material's quality, strength, and suitability for various applications. They include specifications for thickness, alloy type, and surface treatment. International standards such as ASTM B209 (for aluminum sheet and plate) and EN 485 (for aluminum and aluminum alloy sheets) govern the production and use of aluminum sheets in construction. Compliance with these standards is crucial for safety, durability, and to meet regulatory requirements in different regions.</p>

- Q: How do you calculate the weight of an aluminum sheet?

- To calculate the weight of an aluminum sheet, you need to know the dimensions (length, width, and thickness) of the sheet and the density of aluminum. The weight can be calculated by multiplying these three values together and then multiplying it by the density of aluminum.

- Q: What is aluminum curtain wall.

- In the closing means: aluminum curtain wall aluminum panel curtain wall mounted to the side plate finally called closing!On the aluminum ceiling installation knowledge and aluminum product knowledge welcome Baidu Guangzhou "China Hainan" brand aluminum ceiling understanding

- Q: Can the aluminum sheets be used for manufacturing chemical reaction vessels?

- Aluminum sheets are indeed capable of being utilized in the production of chemical reaction vessels. The utilization of aluminum, a versatile substance, presents numerous benefits for this particular purpose. Its lightweight nature, durability, and exceptional resistance to corrosion render it suitable for the containment and interaction of various chemicals. Furthermore, the malleability of aluminum enables it to be easily molded and shaped into the desired design for the vessel, granting flexibility in the manufacturing process. Nevertheless, it is crucial to acknowledge that aluminum may not be suitable for all chemical reactions, particularly those involving highly corrosive or reactive substances. In such instances, alternative materials capable of withstanding the specific conditions of the reaction may prove to be more appropriate.

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, you can use aluminum sheets to create a green building. Aluminum is a sustainable material due to its recyclability and energy efficiency in production. It has a high recycled content rate, reducing the need for raw material extraction. Additionally, aluminum's lightweight nature can lead to reduced energy consumption in transportation and construction. Its durability and resistance to corrosion can extend the life of a building, further contributing to sustainability. However, it's important to consider the entire lifecycle impact, including the energy used in aluminum production, and to source aluminum responsibly to ensure a truly green building.</p>

Send your message to us

Aluminum Plate Sheets - 5 Bars Plate/Tearplate of Good Quality in Hot Sale!

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords