P5 Aluminum Sheets - Aluminium Five Bar Checker Plate with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Five Bar Checker Plate Description:

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. 3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment

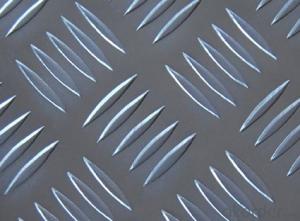

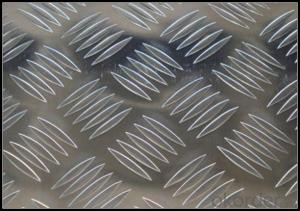

2.Main Features of Aluminium Five Bar Checker Plate :

Low density, light in weight

Anti-corrosion

Strong

Malleable

Naturally good looking

Recyclable

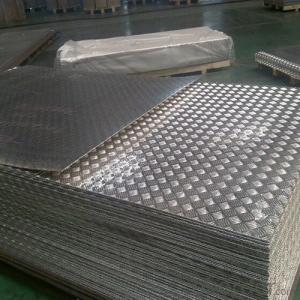

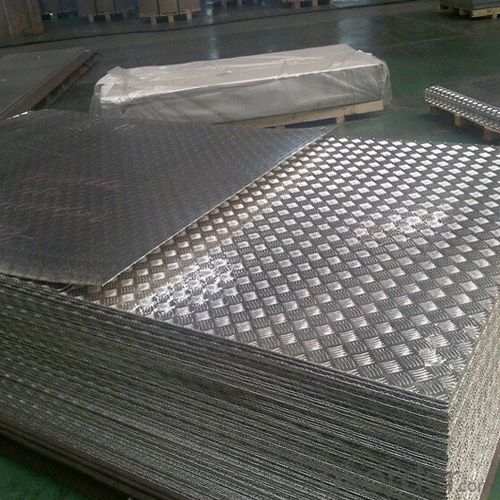

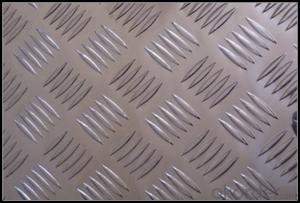

3.Aluminium Five Bar Checker Plate Images:

4. Aluminium Five Bar Checker Plate Specification:

1. | Item | Aluminum coil/ Aluminum strip,1070 aluminium coil | |

2. | Standard | ATSTM B209, JIS H4000-2006,GB/T3190-2008,GB/T3880-2006, etc. | |

3. | Material | 1000 Series:1050,1060,1080,1100,1435,etc. | |

2000 Series:2011,2014,2017,2024,2A12,2A16,2A06,etc. | |||

3000 Series:3002,3003,3004,3104,3204,3030,3A21,etc. | |||

5000 Series:5005,5025,5040,5052,5056,5083,5A05,etc. | |||

6000 Series:6003,6060,6082,6083,6063,6061,etc. | |||

7000 Series:7003,7005,7050,7075,etc. | |||

4. | Specifications | Thickness | 0.01mm~20mm |

Width | 10mm~2000mm | ||

Length | or as required | ||

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Yes, aluminum sheets are suitable for use in food processing and packaging industries. Aluminum is a versatile and widely used material in the food industry due to its excellent properties and advantages. Firstly, aluminum is a non-toxic material, making it safe for direct contact with food. It does not react with food or alter its taste, ensuring the preservation of the original flavor and quality. This is particularly important in the packaging industry, as it helps to maintain the freshness and integrity of the food product. Secondly, aluminum has excellent thermal conductivity, which allows for efficient and even heat distribution during food processing. This property is beneficial for cooking, baking, and other thermal processes, ensuring that food is cooked or processed evenly. Additionally, aluminum sheets offer excellent barrier properties, such as resistance to moisture, light, and gases. This helps to protect food from external factors that could potentially deteriorate its quality, such as moisture or oxygen. It also helps to prolong the shelf life of packaged food products. Furthermore, aluminum sheets are lightweight, yet strong and durable. This makes them easy to handle and transport in food processing and packaging operations. Their strength and durability ensure that the packaging remains intact and protects the food during transportation and storage. Lastly, aluminum is a sustainable material. It is 100% recyclable, meaning that it can be reused without losing its properties. This helps to reduce the environmental impact and supports the circular economy. In conclusion, aluminum sheets are highly suitable for use in the food processing and packaging industries. Their non-toxic nature, thermal conductivity, barrier properties, lightweight yet strong characteristics, and sustainability make them an ideal choice for ensuring the safety and quality of food products.

- Q: Can I bake falafel patties in the oven using an aluminum foil on top of the pan I am using to put in the oven? Will the aluminum foil catch fire in the oven? Also, if I put the aluminum foil I wouldn't have to grease up the foil with oil...the patties just wont stick to aluminum foil right?

- Aluminum foil is just the metal called aluminum which has been pressed into a very thin sheet (foil), and metals won't melt or catch fire here and there till they get extremely hot (in huge furnaces). A home oven is waaay too cool for that. As for sticking, that depends on whether the foil is touching your patties and how much, as well as which ingredients you used in the patties since some will carmelize or dry out onto the foil but only where they contacted. You can always tent or make a dome with the foil so it doesn't touch any of the food though if you're concerned. Not sure why you'd be covering falafels though, since that will steam them (at least partly) not bake, them and therefore not create a crispy exterior.

- Q: Is it possible to utilize aluminum sheets in interior design projects?

- <p>Yes, aluminum sheets can be used for interior design purposes. They are lightweight, durable, and resistant to corrosion, making them suitable for various applications such as wall cladding, ceilings, and furniture. Aluminum sheets can also be painted or anodized to achieve different finishes, adding aesthetic appeal to your design. However, it's important to consider the specific requirements of your project, such as load-bearing capacity and thermal insulation, as these properties can vary with different types of aluminum sheets.</p>

- Q: Can aluminum plate resist acid and alkali?

- The metal oxide film changes the surface state and properties, such as surface coloring, corrosion resistance, abrasion resistance and hardness, and metal surface protection. For example, aluminum anodizing, the aluminum alloy placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, under certain conditions and applied electricity under the electrolysis. Anodized aluminum or its alloy, formed on the surface of alumina thin layer, its thickness is 5~20 microns, anodized aluminum or its alloy. Therefore, the surface hardness and wear resistance of the aluminum alloy were greatly improved by the treatment process.Shanghai Ai Li AI metal materials, dedicated to serve you.

- Q: Can 101 aluminum sheets be CNC machined?

- CNC machining is capable of processing 101 aluminum sheets, allowing for the creation of intricate and accurate cuts, holes, and shapes. This versatile and precise manufacturing process is commonly employed for aluminum materials. It involves computer-controlled machines that remove material from the sheets. The CNC machinability of 101 aluminum sheets is not restricted by their specific alloy designation. Nevertheless, to achieve optimal results, it is crucial to take into account factors like cutting parameters, tool selection, and feed rates when machining these sheets.

- Q: Can someone explain the movement of electrons in a pure block of aluminum metal? At they free to move around between similar energy levels? Are they bound to Al atoms? What about orbital overlap?

- Any element that allows the transfer of electrical flow to move across it usually has the characteristic of having free movement electrons in the outer shell. This is why metals are particularly good at electrical conduction. The best metal for transferring electrical charge is silver followed by copper and then aluminum. Much electrical wire is made from pure aluminum because it is cheaper than copper or silver and the resistance to flow is only slightly lower than copper. The electrons in the outer shells are still bound to the aluminum nucleus but they are free to accept a charge from neighboring aluminum atoms and transfer that charge to the next aluminum in the electrical flow. This is basically the definition of electrical resistance. Copper performs this transfer more efficiently than aluminum so it's electrical resistivity is less than aluminums. But in both base metals, the outer electrons never leave the atom, they simply transfer their charge to the next atom in line

- Q: Can the aluminum sheets be used for manufacturing heat exchanger fins?

- Yes, aluminum sheets can be used for manufacturing heat exchanger fins. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity and corrosion resistance. The lightweight and malleable nature of aluminum sheets make them ideal for forming fins with high surface area to enhance heat transfer. Additionally, aluminum is readily available and cost-effective, making it a popular choice in heat exchanger manufacturing.

- Q: What are the properties of anodized aluminum sheets?

- Anodized aluminum sheets have several distinct properties that make them highly desirable for various applications. Firstly, anodized aluminum sheets have a protective oxide layer on their surface, which enhances their corrosion resistance. This oxide layer is formed through an electrochemical process called anodization, where the aluminum sheet is treated with an electric current in an acid electrolyte solution. This protective layer makes anodized aluminum sheets more durable and capable of withstanding harsh environments, which makes them suitable for outdoor applications. Another notable property of anodized aluminum sheets is their enhanced scratch resistance. The anodization process not only creates a protective layer but also hardens the surface of the aluminum, making it more resistant to scratches and wear. This property is particularly advantageous in applications where the aluminum sheets are subjected to frequent handling or abrasive conditions. Furthermore, anodized aluminum sheets can be produced in a wide range of colors. The anodization process allows for the integration of dyes or pigments into the oxide layer, resulting in a variety of vibrant color options. This property makes anodized aluminum sheets popular in architectural and decorative applications, as they can be customized to match specific design requirements. Additionally, anodized aluminum sheets have excellent thermal and electrical conductivity. The process of anodization does not significantly affect these inherent properties of aluminum. Therefore, anodized aluminum sheets can efficiently dissipate heat and conduct electricity, making them suitable for applications such as heat sinks, electronic enclosures, and electrical components. In summary, the properties of anodized aluminum sheets include enhanced corrosion resistance, improved scratch resistance, a wide range of color options, and excellent thermal and electrical conductivity. These properties make anodized aluminum sheets a versatile and durable material for various industries and applications.

- Q: Is aluminum sheet magnetic?

- No, aluminum sheet is not magnetic.

- Q: What is the weight per square foot of 101 aluminum sheets?

- The weight per square foot of 101 aluminum sheets varies depending on the thickness of the sheets. Please provide the thickness of the aluminum sheets to determine the weight per square foot accurately.

Send your message to us

P5 Aluminum Sheets - Aluminium Five Bar Checker Plate with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords