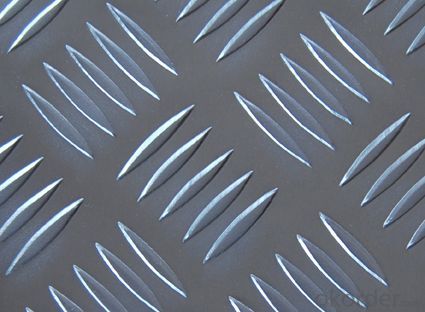

Aluminum Sheets for Walls - Alu Plate with 5 Bars Pattern

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Alu Plate

Aluminum trade plate have great suctility,heat conductivity, anti-corrosion and moisture resistance properties.

Alloy: AA1050,1060, 1100, AA3003, 3005, 3015, 5052, 5754, 5083,8011, etc

Temper: H14/16/18/22/24/32,HO etc.

Thickness:0.2mm—100mm

Width:100mm—2300mm (Can be slitted)

Application:

Anti-sliperypurpose in vehicles, packing and appliance, decorative purpose

Features:

1. Excellent quality of products

2. Quick delivery

3. Best service to clients

4. BV,SGS avalible

5. No buckle o waveness

6. Tension leveling

7. Certificate of Origin

8. Form A,E

Packaging Detail: Carton ,Wooden pallet with plastic protection packing,standard seaworthy packing or as your request.

ProductionCapacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

Coveredfactories with full production line

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

30 day after client’s deposit

- Q: Can aluminum sheet be used for electrical grounding applications?

- Indeed, aluminum sheet finds utility in electrical grounding applications. It possesses remarkable conductive properties, rendering it apt for employment in grounding systems. Its low resistance and exceptional electrical conductivity make it a common choice in diverse electrical applications. With the capability to proficiently transport electrical current and securely disperse it into the ground, aluminum sheet guarantees the safeguarding of electrical systems and averts potential electrical dangers. Moreover, the lightweight and corrosion-resistant attributes of aluminum establish it as a favored option for grounding applications across numerous industries, encompassing construction, automotive, and aerospace.

- Q: Can 101 aluminum sheets be bent without cracking or breaking?

- 101 aluminum sheets can be bent without cracking or breaking if proper bending techniques are employed. Aluminum 101 is a relatively soft and malleable alloy, making it suitable for bending. However, it is important to consider the thickness of the sheets and the radius of the bend. Thicker sheets may require more force to bend, increasing the risk of cracking. Additionally, sharp bends with a small radius may also cause cracking. To prevent this, it is recommended to use a bending machine or tool specifically designed for aluminum bending. This will ensure even pressure distribution and minimize the risk of cracking or breaking. Overall, while 101 aluminum sheets can generally be bent without issue, it is crucial to apply appropriate techniques and consider the specific parameters to avoid any potential damage.

- Q: Other then pop cans, what else is aluminum that can be recycled?

- Anything made of aluminum can be recycled. Aluminum cans are just a visible item that can be used for social engineering purposes. The cans also are very pure form of the metal. You will find aluminum in many things, from parts in your computer, major parts in your family car, pots, pans, kitchen items, tools, display items, structural supports for various things, boats, canoes, airplanes, and the list is long. Fact is, it would be difficult to find many items where aluminum was NOT used. Although everything that is metal that a magnet would not stick to, is not always aluminum. ANY metal can be recycled, and most metals can be sorted for recycling when you find a recycling plant that will buy the materials. Some of the metals need to be in large quantity, or weight in order to be worthwhile sorting. Some things like batteries can be sorted by general type. Some of those are easier to break down to component metals than others. Some have hazardous substances in them so need care in storage, and some have hazardous substances that need special care in shipping them. But they are exception.

- Q: How do you prevent warping of aluminum sheets during machining?

- There are several measures that can be taken to prevent warping of aluminum sheets during machining: 1. Proper material selection is crucial in minimizing warping. Opt for aluminum alloys with lower levels of thermal expansion, like 6061 or 7075, as they are less prone to warping. 2. It is recommended to stabilize the material before machining by annealing or stress-relieving the aluminum sheets. This process reduces internal stresses and decreases the likelihood of warping. 3. Ensure the use of appropriate cutting tools. Opt for tools with sharp edges and proper geometry to minimize heat generation and facilitate efficient chip removal. Carbide or diamond-coated tools are often preferred for their high heat resistance when machining aluminum. 4. Minimize heat generation during machining, as excessive heat can cause warping. Implement the use of coolant or lubricants to reduce friction and dissipate heat. Continuous cooling helps maintain a stable temperature and prevents warping. 5. Properly control cutting parameters such as cutting speed, feed rate, and depth of cut to prevent warping. High cutting speeds or excessive material removal rates generate excessive heat, which leads to warping. Experimentation and experience should determine the optimal parameters. 6. Use appropriate fixturing during machining to minimize the chances of warping. Securely clamp the aluminum sheets using suitable fixtures or jigs to maintain stability and prevent movement. 7. Consider employing machining techniques like climb milling or ramping, which reduce vibrations and ensure a smoother cutting process, thereby reducing the risk of warping. 8. After machining, it is advisable to stress-relieve the aluminum sheets again. This step further reduces any residual stress that may have developed during the machining process. By adhering to these steps, the chances of warping during the machining of aluminum sheets can be significantly reduced, resulting in high-quality finished products.

- Q: Can the aluminum sheets be used for manufacturing chemical reactors?

- Yes, aluminum sheets can be used for manufacturing chemical reactors.

- Q: Can the aluminum sheets be used for manufacturing aircraft engine components?

- Yes, aluminum sheets can be used for manufacturing aircraft engine components. Aluminum is a commonly used material in the aerospace industry due to its excellent strength-to-weight ratio and corrosion resistance. It is lightweight, yet strong enough to withstand the stresses and high temperatures associated with aircraft engines. Additionally, aluminum sheets can be easily fabricated, making them suitable for producing intricate engine components. Overall, aluminum sheets are a preferred choice for manufacturing aircraft engine components due to their favorable mechanical properties and suitability for aerospace applications.

- Q: What is the typical wear resistance of aluminum sheets?

- The typical wear resistance of aluminum sheets can vary depending on the specific alloy and temper of the sheet. Generally, aluminum sheets have a moderate wear resistance compared to other metals. However, they are not as wear-resistant as materials such as steel or titanium. Aluminum sheets can withstand light to moderate wear and abrasion, making them suitable for applications where they are not subjected to excessive friction or impact. To enhance the wear resistance of aluminum sheets, they can be treated with coatings or surface treatments such as anodizing or painting. Additionally, the thickness and hardness of the aluminum sheet can also affect its wear resistance, with thicker and harder sheets generally offering better resistance to wear.

- Q: What are the different grades of aluminum sheets?

- There are several different grades of aluminum sheets available in the market, each with its own unique properties and uses. The most commonly used grades include 3003, 5052, and 6061. - Grade 3003: This is a non-heat treatable alloy that is highly resistant to corrosion. It is often used in applications where corrosion resistance is essential, such as in packaging, cooking utensils, and chemical equipment. - Grade 5052: This grade is also non-heat treatable and offers excellent corrosion resistance. It is known for its strength and durability, making it suitable for marine applications, transportation equipment, and architectural purposes. - Grade 6061: This is a heat treatable alloy that combines good corrosion resistance with high strength. It is widely used in structural applications, such as in aircraft components, automotive parts, and construction materials. Apart from these grades, there are also other specialized aluminum alloys available, such as 2024, 7075, and 5083, which offer specific properties for particular industries or applications. It is important to consider the specific requirements of your project before choosing a grade of aluminum sheet, as each grade has its own strengths and limitations. Consulting with a knowledgeable supplier or expert can help you determine the most suitable grade for your needs.

- Q: Can aluminum sheets be anodized with custom designs?

- Yes, aluminum sheets can be anodized with custom designs. Anodizing is an electrochemical process that enhances the natural oxide layer on the surface of aluminum, making it more durable and corrosion-resistant. During this process, different patterns and designs can be added to the aluminum sheet by masking off certain areas and exposing others to the anodizing solution. This allows for custom designs to be etched or dyed onto the surface, creating unique and personalized finishes. Anodized aluminum sheets with custom designs are commonly used in various industries, including architecture, automotive, and electronics, to achieve aesthetic and functional requirements.

- Q: Can aluminum sheet be anodized?

- Indeed, it is possible to anodize aluminum sheet. Anodization, an electrochemical process, fortifies the natural oxide layer on the aluminum's surface, resulting in increased thickness, durability, and suitability for diverse applications. The procedure entails submerging the aluminum sheet into an electrolyte solution and passing an electric current through it. This prompts the release of oxygen ions from the electrolyte, which then combine with the aluminum, generating a fresh layer of aluminum oxide. Anodization allows for the creation of an array of colors on the aluminum sheet's surface, enhances its resistance to corrosion, and provides an improved surface for the adhesion of paints or coatings.

Send your message to us

Aluminum Sheets for Walls - Alu Plate with 5 Bars Pattern

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords