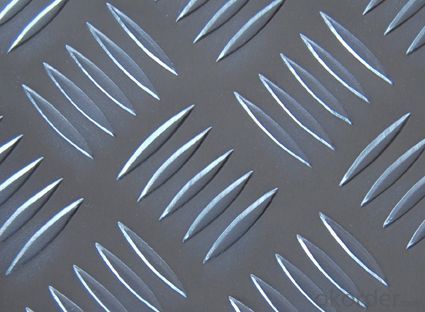

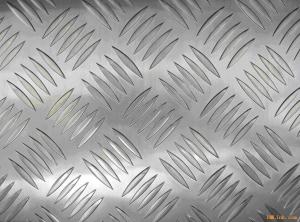

Commercial Aluminum Sheets - Big Five Bars Al Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (asmuch as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Secification:

Finishing:Mill Finish, Painted, One Side Bright, Brushed and Coil Anodizing available onrequest

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754,5083,8011, etc

Temper:H14/16/18/22/24/32,HO etc.

Thickness: 0.2mm—100mm

Width: 100mm—2300mm(Can be slitted)

Standard:GB/T 3880-2006 ASTM B-209

Features:

1. Excellent quality of products

2. Quick delivery

3. Best service to clients

4. BV,SGS avalible

5. No buckle o waveness

6. Tension leveling

7. Certificate of Origin

8. Form A,E

Packaging Detail: Carton ,Wooden pallet with plastic protection packing,standard seaworthy packing or as your request.

ProductionCapacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

Coveredfactories with full production line

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

30 day after client’s deposit

- Q: What is aluminium oxide sheet?

- The aluminum oxide plate is placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, and electrolysis is carried out under certain conditions and applied current. Anodized aluminum plate on the surface of the formation of alumina thin layer, its thickness is 5~20 microns, hard anodized film up to 60~200 microns.

- Q: Can aluminum sheets be coated with other materials?

- Yes, aluminum sheets can be coated with other materials. Aluminum is a versatile metal that can be easily coated with various substances, such as paints, lacquers, polymers, and specialty coatings. These coatings can enhance the appearance, durability, corrosion resistance, and thermal or electrical properties of the aluminum sheets.

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Aluminum sheets are indeed appropriate for utilization in the food processing and packaging sectors. The food industry extensively employs aluminum due to its exceptional properties and advantages. To begin with, aluminum is a safe material for direct contact with food as it is non-toxic. It does not react with food or affect its taste, guaranteeing the preservation of the original flavor and quality. This is particularly crucial in packaging, as it aids in maintaining the freshness and integrity of the food product. Moreover, aluminum possesses excellent thermal conductivity, enabling efficient and uniform heat distribution during food processing. This attribute is advantageous in cooking, baking, and other thermal procedures, ensuring that food is cooked or processed evenly. Additionally, aluminum sheets exhibit outstanding barrier properties, including resistance to moisture, light, and gases. This shields food from external factors that could potentially degrade its quality, such as moisture or oxygen. It also extends the shelf life of packaged food products. Furthermore, aluminum sheets are lightweight, yet sturdy and durable. This makes them easy to handle and transport in food processing and packaging operations. Their strength and durability ensure that the packaging remains intact and safeguards the food during transportation and storage. Lastly, aluminum is an environmentally sustainable material. It is fully recyclable, meaning it can be reused without losing its properties. This aids in reducing the environmental impact and supports the concept of a circular economy. In conclusion, aluminum sheets are highly suitable for use in the food processing and packaging industries. Their non-toxic nature, thermal conductivity, barrier properties, lightweight yet strong characteristics, and sustainability make them an ideal choice for ensuring the safety and quality of food products.

- Q: Do 101 aluminum sheets have any specific sound or vibration damping properties?

- Yes, 101 aluminum sheets have specific sound and vibration damping properties. Aluminum is known for its high damping capacity, which means it can effectively reduce vibrations and dampen noise. The specific properties of 101 aluminum sheets make them excellent choices for applications where sound and vibration control are desired, such as in the automotive and aerospace industries.

- Q: Are 101 aluminum sheets suitable for chemical processing equipment?

- Chemical processing equipment should not employ 101 aluminum sheets due to their unsuitability. Although aluminum is a versatile and extensively utilized material, its use is not advisable when dealing with potent acids or bases. Aluminum is prone to corrosion when exposed to certain chemicals, jeopardizing the equipment's integrity and potentially causing leaks or other safety risks. Therefore, it is advisable to opt for materials explicitly engineered and produced to endure the corrosive impacts of the chemicals employed in chemical processing equipment.

- Q: What is the weight of aluminum sheets per square foot?

- The weight of aluminum sheets per square foot can vary depending on the thickness or gauge of the sheet. On average, a 1/8 inch thick aluminum sheet weighs around 1.9 pounds per square foot. However, thinner sheets may weigh less, while thicker sheets can weigh more. It is important to consider the specific thickness of the aluminum sheet when determining its weight per square foot.

- Q: What are the different methods of surface cleaning for adhesive bonding of aluminum sheet?

- There are several methods of surface cleaning for adhesive bonding of aluminum sheet. These methods include mechanical cleaning, chemical cleaning, and conversion coating. Mechanical cleaning involves using abrasive materials or techniques such as sanding, wire brushing, or blasting to remove any dirt, debris, or oxidation from the surface of the aluminum sheet. Chemical cleaning involves using solvents or detergents to dissolve and remove contaminants from the surface. Conversion coating methods, such as phosphating or chromating, create a protective layer on the surface of the aluminum sheet, improving its adhesion properties and resistance to corrosion.

- Q: This question asks whether it is possible to utilize stamped or embossed aluminum sheets for a specific project.

- <p>Yes, you can use stamped or embossed aluminum sheets in your project. These sheets are known for their strength, durability, and lightweight properties, making them ideal for various applications such as construction, automotive, and aerospace. Stamped aluminum sheets are formed by pressing the material into a specific shape, while embossed sheets have a raised pattern. Both types offer design flexibility and can be customized to meet specific project requirements. Ensure that the aluminum sheets you select meet the necessary specifications for your project, such as thickness, strength, and finish.</p>

- Q: i know the 4100 is aluminum........im wondering if this one is also..

- Yes, the whole thing is aluminum

- Q: Can aluminum sheets be painted or coated with different colors?

- Yes, aluminum sheets can be painted or coated with different colors. Aluminum is a versatile material that can be easily painted or coated to achieve various colors and finishes. The process typically involves pre-treating the surface, applying a primer, and then applying the desired paint or coating. This allows for customization and aesthetic enhancement of aluminum sheets in numerous applications.

Send your message to us

Commercial Aluminum Sheets - Big Five Bars Al Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords