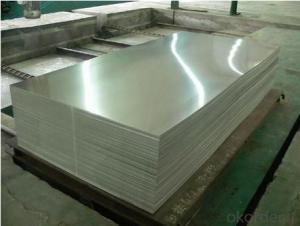

Commercial Aluminum Baking Sheets for Imprinting and Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

ALLOY : AA1***(AA1050,AA1060,AA1070,AA1100etc)

AA3***(AA3003,AA3004,AA3005,AA3105etc)

AA5***(AA5052 etc)

TEMPER:H14,H18,H24,H26,H32

THICKNESS:0.2mm-20mm

WIDTH:10mm-1500mm

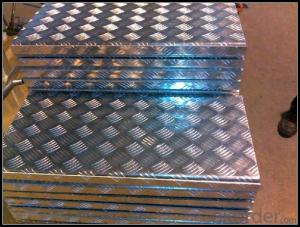

EMBOSSED PATTERNS : Diamond, stucoo,bars etc

STANDARD: GB/T3880-2006

Special specification is available on customer's requirement

Product Description

Goods name | Aluminum plate |

alloy | Yes |

Plance of origin | China |

Quality | Prime quality |

Certificate | ISO9001 |

Grade | 3000 Series |

Thickness | 0.3-150mm |

Type | Plate |

Width | 300-1950mm |

Model number | 3003,3004,3005,3014,3105 |

Surface | Mill finish |

Temper | O-H112 |

Ensure | we can supply customers' with different specifications of the highest quality and lowest price. Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit. |

- Q: What are the common sizes of aluminum sheet?

- Some common sizes of aluminum sheet include 4x8 feet (48x96 inches), 4x10 feet (48x120 inches), and 5x10 feet (60x120 inches).

- Q: What are the different grades of aluminum sheets available?

- There are several different grades of aluminum sheets available, including 1100, 3003, 5052, and 6061. These grades vary in terms of their composition, strength, and intended use. 1100 aluminum is the most commercially pure grade and is often used for general purpose applications. 3003 aluminum is alloyed with manganese and has improved strength and corrosion resistance. 5052 aluminum is alloyed with magnesium and has excellent weldability and formability. 6061 aluminum is alloyed with magnesium and silicon and is known for its high strength and versatility.

- Q: I have tried every possible method that I could find on the web for cleaning aluminum, tungsten, filler wire. Nothing has seemed to work. I've tried looking for leaks in the argon line. I'm getting decent welds but there is gunk in the welds for sure. I'm worried about overall strength of the welds. Does anybody out there know of a tried and true method for cleaning aluminum, tungsten, filler etc. that is sure to work? If I can follow that method and still have problems It could possibly be a problem with the machine. Any help would be much appreciated.

- Preweld cleaning requires two operations: oil/grease removal and oxide removal. As below, remove oils and greases first, then remove the oxide. Don’t reverse this order. Take the following steps before welding aluminum: 1. Remove oil, grease, and water vapor using an organic solvent such as acetone or a mild alkaline solution like a strong soap. You may also use citrus-based degreasers, but be sure to rinse and dry the part before welding. 2. Remove surface oxides with a stainless steel wire brush (used only for aluminum) or strong alkaline or acid. Many welding suppliers sell oxide-removal solutions in spray or squeeze bottles for local application. Exercise extreme care when handling these solutions, and again, rinse and dry the part before welding. 3. Assemble the joint. If it won't be welded immediately, cover the joint with brown Kraft paper to prevent dirt and grit in the air from getting into the joint. 4. Keep the aluminum dry and at room temperature. 5. Weld within a few days. Clean the joint again if it isn't welded within that time. Good luck!!!

- Q: Are aluminum sheets suitable for electrical transformers?

- Indeed, electrical transformers can certainly make use of aluminum sheets. Aluminum, being a highly conductive material, presents numerous benefits when employed in transformers. Primarily, its electrical resistance is lower in comparison to other materials such as copper, enabling efficient transmission of electrical energy. Consequently, this leads to reduced energy losses and enhanced overall performance. Furthermore, aluminum possesses the advantage of being lightweight, rendering it easier to handle and install. Moreover, it is also more economical than copper, thus making it the preferred option for extensive transformer applications. All in all, aluminum sheets offer a dependable and effective resolution for electrical transformers.

- Q: What are the potential environmental issues that arise from the use of aluminum sheets?

- <p>Yes, there are environmental concerns related to using aluminum sheets. The production process is energy-intensive and contributes to greenhouse gas emissions. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The disposal of aluminum waste can also lead to pollution if not properly managed. However, aluminum is highly recyclable, which can mitigate some of these concerns if recycling practices are adopted widely.</p>

- Q: some car manufactures use aluminium car body on a steel sub-frame. explain, using electrode potential what would happen if a weak acid was to become trapped in the space between these two metals!! any current plzz help, its for my assignment, and i dont understand

- Most reactive metal will corrode first.

- Q: Can aluminum sheets handle high temperatures?

- Yes, aluminum sheets can handle high temperatures. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), making it suitable for many high-temperature applications. Additionally, aluminum has excellent thermal conductivity, which allows it to quickly dissipate heat. This property makes aluminum sheets suitable for use in areas that require high-temperature resistance, such as engine components, heat exchangers, and oven linings. However, it is important to consider the specific alloy and thickness of the aluminum sheet, as different alloys may have varying temperature limits.

- Q: What are the standard sizes and availability of aluminum sheets in the market?

- The standard sizes and availability of aluminum sheets in the market can vary, but some common sizes include 4x8 feet, 4x10 feet, and 5x10 feet. Additionally, aluminum sheets are often available in various thicknesses ranging from 0.02 inches to 0.25 inches or more. It is important to note that availability may depend on the specific supplier or manufacturer, as they may offer custom sizes or larger sheets upon request.

- Q: Are aluminum sheets suitable for artistic sculptures?

- Yes, aluminum sheets are suitable for artistic sculptures. Aluminum is a versatile material that offers several advantages for sculpting purposes. Firstly, it is lightweight, making it easier to handle and manipulate. This allows artists to create intricate and detailed sculptures without compromising on structural integrity. Additionally, aluminum is highly malleable, meaning it can be shaped into various forms and contours. This allows artists to experiment with different designs and achieve the desired artistic expression. Furthermore, aluminum is resistant to corrosion and weathering, making it ideal for outdoor sculptures. Its durability ensures that the artwork will withstand the elements and retain its aesthetic appeal over time. Additionally, aluminum sheets can be easily welded or joined together, enabling artists to create larger and more complex sculptures. Overall, aluminum sheets provide artists with a flexible and durable material that allows for creativity and longevity in their sculptural works.

- Q: Are aluminum sheets suitable for boat building?

- Yes, aluminum sheets are suitable for boat building. Aluminum is a popular material choice for boat construction due to its numerous advantageous properties. Firstly, aluminum is lightweight, which makes it easier to handle and transport during the boat building process. This lightweight characteristic also contributes to better fuel efficiency and improved overall performance of the boat. Additionally, aluminum is highly resistant to corrosion, especially in saltwater environments, making it an ideal choice for boat building. This resistance to corrosion ensures that the boat remains durable and maintains its structural integrity for a longer period of time, even when exposed to harsh weather conditions. Furthermore, aluminum sheets offer excellent strength-to-weight ratio, providing a sturdy and reliable structure for the boat. This strength allows the boat to withstand the forces encountered while sailing, ensuring a safe and enjoyable experience for the occupants. Moreover, aluminum is a versatile material that can be easily molded and shaped into various boat designs. This flexibility allows for customization and the creation of unique boat designs that meet specific requirements and preferences. Lastly, aluminum is a sustainable and environmentally friendly material. It is fully recyclable, reducing the environmental impact of boat building and promoting a greener approach to marine construction. In conclusion, aluminum sheets are indeed suitable for boat building due to their lightweight nature, corrosion resistance, strength, versatility, and eco-friendliness.

Send your message to us

Commercial Aluminum Baking Sheets for Imprinting and Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords