Aluminum Print Sheets for Point-Fixing Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

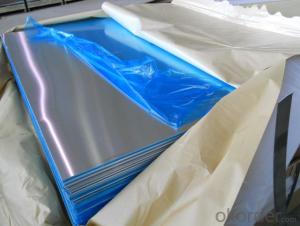

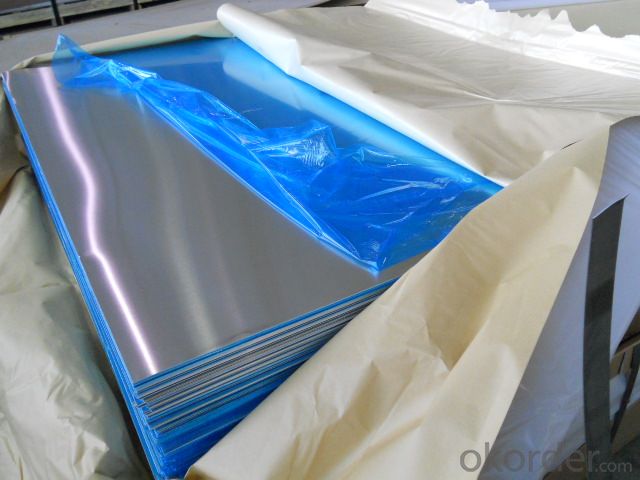

1.Structure of Aluminium Sheets for Point-fixing Curtain Walls Aluminium sheets for point-fixing curtain walls are one type of non-frame curtain wall than consist of glass panels, point-fixing components on such panels and their supporting structures. . Aluminium sheets for point-fixing curtain walls are good at ductility, heat conductivity, anti-corrosion and moisture resistance. They are widely used in roofing, electronics, instruments, lighting decoration, packing, decoration, curtain wall, sandwich panels, boats, etc. 2.Main Features of Aluminium Sheets for Point-fixing Curtain Walls •High intensity •Easy to be processed and shaped •Weather resistance •Anti-pollution & environment protection 3. Aluminium Sheets for Point-fixing Curtain Walls Images 4.Specification of Aluminium Sheets for Point-fixing Curtain Walls Alloy AA1050,AA1060, AA1070, AA1100 Temper: H12, H14, H16, H18, H22, H24, H26, H32,HO, F Thickness: 0.10-500mm Width: 10mm- 2200mm Standard: GB/T3880-2006, ASTM, ISO, EU standard Special Specification is available on customer’s requirement 5.FAQ A.What about inspections to guarantee quality? For each order for Aluminum Sheets, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods. With requirement of customers, we also can arrange the third party inspection. B.What about delivery? We will put order for Aluminum Sheets in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity. C.What is the MOQ? 5 tons for each size. D. What about your main markets for aluminium sheets? Main markets include South East Asia, Middle East, North America, Southc.

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Certain applications can consider aluminum sheets as an alternative to glass. Aluminum sheets provide various benefits over glass, making them suitable for specific scenarios. To begin with, aluminum sheets possess lightweight and durable characteristics, making them an excellent choice for industries like aerospace or automotive, where weight is a concern. Conversely, glass is relatively heavy and brittle, limiting its usage in certain environments. Moreover, aluminum sheets exhibit exceptional resistance to corrosion, making them a suitable option for marine or coastal applications, where glass may deteriorate over time due to exposure to saltwater. Aluminum sheets also possess a high strength-to-weight ratio, enabling greater design flexibility and structural integrity compared to glass. Furthermore, aluminum sheets offer superior thermal insulation properties in comparison to glass. They provide improved resistance to heat transfer, which is advantageous in applications where temperature control is crucial, like the construction industry. Additionally, aluminum sheets can be more cost-effective than glass in specific applications. The production and installation costs of aluminum sheets are often lower than glass, making them a more economical choice for large-scale projects. However, it is important to acknowledge that glass retains its own unique properties and advantages, such as transparency and optical clarity. Glass also has better resistance to scratches and chemical corrosion when compared to aluminum sheets. In conclusion, while aluminum sheets can serve as a viable alternative to glass in certain applications due to their lightweight, durability, corrosion resistance, thermal insulation properties, and cost-effectiveness, the final decision between the two materials depends on the specific requirements and limitations of the application at hand.

- Q: What is the price range of aluminum sheets?

- The price range of aluminum sheets can vary depending on factors such as size, thickness, and quality. However, generally speaking, aluminum sheets can range in price from $1 to $5 per square foot.

- Q: 3003H24 alloy aluminum plate refers to what kind of aluminum plate?

- Attached: O status: fully annealed to obtain the lowest strength of the processing products. 8 state: hard working state (9)To sum up: 3003 refers to the aluminum manganese alloy, H24 represents the process of rolling, through incomplete annealing to achieve the specified strength, hardness of an aluminum substrate. In addition to the 5 first series of aluminum magnesium alloy used in aluminum plate, the other 4 prefix silicon as the main alloying elements in zinc series, as the elements of the 7 prefix series.

- Q: Aluminum or steel bike frame cost more???...which one cost the most usually???

- Good quality steel frames are almost always more expensive than aluminum. There are a couple of reasons for this... 1) Aluminum is always welded. This takes much less effort and time than a fine brazed steel unit; 2) High quality steel tubing is very expensive compared to aluminum due to the thin walls and sometimes exotic alloying materials; 3) Aluminum is one of the most common elements on the planet. Common steel alloys have harder-to-obtain elements such as molybdneum, manganese, and other rare metals. 4) Although many aluminums require post weld processing it takes little or no labor to complete it while a high quality steel frame responds beautifully to hand work. 5) A good steel frame is simply harder to find nowadays. I know that this goes beyond the scope of your question, but keep in mind that regardless of the aluminum alloy it all weighs the same; regardless of the steel alloy it all weighs the same. The difference in weight comes from modifying the metal mixture, enabling a stronger metal and making of ever-thinner tubes. Kojman47 (below) is WAAY off in his interpretation of materials. There are steel frames that rival the weight and strength of titanium which is often 1/2 the weight of aluminum. There is no such thing as cromolly. The correct name (if I may) is Chrome Molybdneum, abbreviated as CrMo, often called Chrome Moly. Cromoly or cromolly or cromo doesn't give proper respect to the alloy OR to the frame. CrMo (cromolly in Kojmans eyes) is steel.

- Q: doesn't particularly need to be welding but i need to make an air tight permanent seal around 2 very thin sheets of aluminium (like .02 inches thick) i was thinking .02 inch 5052 aluminum because its the thinnest i can find but am obviously up for suggestions.

- May be you can use spot welding.But may be that would not give you an air tight permanent seal.So,you can go for Hydraulic pressing as in FERRARI 599 GTO's exhaust.(QUITE EXPENSIVE to be done at personal level)

- Q: Are aluminum sheets resistant to vibration?

- Yes, aluminum sheets are generally resistant to vibration due to their inherent strength and durability. The high stiffness-to-weight ratio of aluminum, along with its ability to dampen vibrations, makes it an ideal material for applications requiring vibration resistance.

- Q: Are aluminum sheets suitable for HVAC systems?

- Indeed, HVAC systems find aluminum sheets to be a fitting choice. As a lightweight and sturdy material, aluminum boasts exceptional thermal conductivity, rendering it highly suitable for integration into HVAC systems. It frequently serves as the base for crafting ductwork, heat exchangers, and fins within air conditioning units. Moreover, aluminum sheets exhibit corrosion resistance, which proves advantageous in settings with elevated humidity levels or instances of moisture exposure. Furthermore, aluminum stands as an eco-friendly alternative as it can be recycled, solidifying its status as an environmentally conscious option for HVAC systems. All in all, aluminum sheets present a multitude of advantages and remain widely embraced within the HVAC industry.

- Q: Are aluminum sheets suitable for electrical connectors?

- Yes, aluminum sheets are suitable for electrical connectors. Aluminum is a highly conductive metal, which makes it an excellent choice for transferring electric current. It has a low electrical resistance, allowing for efficient transmission of electricity. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective, making it a popular material for electrical connectors in various industries such as automotive, aerospace, and electronics. However, it is important to note that aluminum connectors may require additional measures to prevent galvanic corrosion when used with dissimilar metals.

- Q: Can aluminum sheets be used for decorative ceilings?

- Indeed, decorative ceilings can utilize aluminum sheets. The versatility of aluminum allows for the creation of a multitude of designs and patterns, resulting in visually pleasing ceilings. Its lightweight nature, durability, and resistance to corrosion make it a favored choice for decorative purposes. Furthermore, aluminum sheets can be powder-coated or painted in various colors, enabling them to align with the desired aesthetic of any given space. Regardless of whether the purpose is residential or commercial, aluminum sheets provide a contemporary and fashionable option for crafting decorative ceilings.

Send your message to us

Aluminum Print Sheets for Point-Fixing Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords