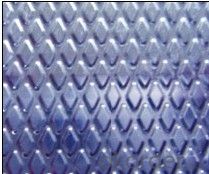

Scale Diamond Plate Aluminum Sheets with Better Price in Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series,7000 series, 8000 series,etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1500*3000mm,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 400mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 4 tons/each size.

How many tons did you export in one year

Fiji,Indonesia,Canada, Vietnam,Turkey,etc.

What is your basic products?

---Normally they are aluminum sheet,big and small-5-bar aluminium checkered sheet, big-5-bar checkered aluminium plate, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Can the aluminum sheets be used for manufacturing medical equipment?

- Yes, aluminum sheets can be used for manufacturing medical equipment. Aluminum is a versatile and lightweight metal that offers excellent strength and durability, making it suitable for various medical applications. It is commonly used in the production of surgical instruments, prosthetics, medical carts, and equipment housings due to its corrosion resistance and ease of sterilization.

- Q: What are the potential health risks associated with handling aluminum sheets?

- <p>Working with aluminum sheets can pose certain health concerns, primarily due to inhalation of aluminum dust or fumes. Long-term exposure may lead to respiratory issues and potentially neurological problems. Aluminum dust can cause irritation to the eyes, nose, and throat. In some cases, it may contribute to the development of Alzheimer's disease, although this link is still debated. It's important to follow safety guidelines, such as using proper ventilation and wearing protective gear like masks and gloves, to minimize these risks.</p>

- Q: What is the typical hardness of aluminum sheets?

- The typical hardness of aluminum sheets can vary depending on the specific alloy and temper. However, aluminum sheets generally have a hardness ranging from 40 to 70 on the Brinell hardness scale (HB). This level of hardness allows aluminum sheets to be easily formed, machined, and fabricated, making them suitable for a wide range of applications in industries such as aerospace, automotive, construction, and manufacturing. It is important to note that the hardness of aluminum sheets can be further enhanced through heat treatment processes, such as annealing or hardening, to meet specific requirements and improve their mechanical properties.

- Q: What are the different machining options for aluminum sheets?

- Depending on the specific requirements of the project and the desired outcome, there are several machining options available for aluminum sheets. Some commonly used methods for machining aluminum sheets include: 1. Cutting: Aluminum sheets can be cut using various techniques such as shearing, sawing, or laser cutting. Shearing involves applying high force with a shearing machine to achieve a clean and straight cut. Sawing utilizes a saw blade to cut through the aluminum sheet, while laser cutting uses a high-powered laser beam to melt or vaporize the aluminum for precise and accurate cuts. 2. Drilling: Drilling is a frequently employed machining option to create holes in aluminum sheets. This process involves using a drill bit to remove material from the sheet and create holes with the desired diameter. Different drill bits can be utilized to achieve specific hole sizes and shapes. 3. Milling: Milling is a versatile machining option that can be used to create intricate shapes and contours in aluminum sheets. This process involves using a rotating cutting tool to remove material from the sheet, resulting in precise and accurate finishes. Depending on the project's complexity, milling can be performed using various types of milling machines, such as vertical milling machines or CNC milling machines. 4. Turning: Turning is another machining option commonly employed for aluminum sheets, particularly when shaping cylindrical or conical forms. This process involves rotating the aluminum sheet against a cutting tool, which removes material and shapes the sheet according to the desired dimensions. Turning can be carried out manually on lathes or using CNC turning machines for higher precision. 5. Bending: Bending is a frequently used machining option to create curved or angled shapes in aluminum sheets. This process involves applying force to the sheet, causing it to deform and take on the desired shape. Bending can be done manually using tools like a brake press or using hydraulic or CNC press brakes for more accurate and consistent results. These are just a few of the machining options available for aluminum sheets. The choice of method will depend on factors such as the desired outcome, project complexity, and available resources. It is crucial to select the most suitable machining option to efficiently and effectively achieve the desired results.

- Q: How much is a square inch of a millimeter aluminum plate?

- Weight 2.68 kg / square meterThis explanation is not difficult to explain the same square metre. Why is the weight different?

- Q: How do aluminum sheets perform in extreme weather conditions?

- Aluminum sheets are renowned for their exceptional performance in extreme weather conditions, as they possess inherent properties that render them highly resistant to corrosion and capable of enduring harsh environmental elements like rain, snow, and extreme temperature fluctuations. When confronted with hot weather, aluminum sheets possess the ability to reflect sunlight and dispel heat, thereby averting any warping or deformation. This characteristic renders them suitable for utilization in regions characterized by high temperatures or direct exposure to sunlight. Similarly, in cold weather, aluminum sheets retain their strength and do not become brittle, making them dependable in freezing temperatures or regions prone to heavy snowfall. With a low coefficient of thermal expansion, they can withstand contraction and expansion without any detrimental effects such as cracking or damage. Moreover, aluminum sheets exhibit excellent resistance to moisture, which safeguards them against rusting or corroding when exposed to rain or high levels of humidity. This quality makes them an ideal choice for employment in coastal areas or regions with substantial rainfall. Additionally, aluminum sheets possess the advantage of being lightweight yet durable, enabling them to withstand high winds and severe storms without compromising their structural integrity. This quality positions them as the preferred option for applications such as roofing, siding, and outdoor signage in areas susceptible to hurricanes or strong winds. All in all, aluminum sheets display remarkable performance in extreme weather conditions, which establishes them as a reliable and versatile material for various outdoor applications.

- Q: My aluminum storm windows are wasting energy in my home, however, the $7000 estimate to replace them is beyond (well beyond) my comfort zone.I know aluminum is a great conductor of hot and cold. I was considering cleaning the frames, and then coating them with a brush on clear or possibly white liquid rubber to reduce the conductivity. Any idea as to how much benefit I'll realize? Is flammability going to be an issue?I need some solid answers please. Trolls go get your two points elsewhere.Thanks.Your help is much appreciated.

- Plastic coating will not stick to aluminum well. You will have to sand it first then use a aluminum metal primer. This is very labor intensive and you would be better off making new frames from wood or vinyl

- Q: This question asks for a comparison between aluminum sheets and other lightweight materials like plastic and glass, focusing on their properties and uses.

- <p>Aluminum sheets are lightweight yet strong, offering excellent strength-to-weight ratios. They are more durable and heat resistant compared to plastics, which can deform under heat and are less sturdy. Unlike glass, aluminum is less brittle and does not shatter, making it safer for certain applications. Additionally, aluminum is recyclable and has good thermal and electrical conductivity, which is not the case with plastics. However, plastics are generally cheaper and easier to shape into complex forms, while glass offers better transparency for applications requiring clear visibility. Each material has its advantages depending on the specific requirements of the application.</p>

- Q: Can the aluminum sheets be used for reflector applications?

- Yes, aluminum sheets can be used for reflector applications as they have excellent reflective properties due to their high reflectivity and low absorption of light.

- Q: What is the density of the 1100 aluminum plate?

- 1100 aluminum plate is generally used in utensils, heat sink, caps, printing plates, building materials, heat exchanger components, but also can be used as deep stamping products. It is widely used in various fields ranging from cooking utensils to industrial equipment.

Send your message to us

Scale Diamond Plate Aluminum Sheets with Better Price in Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords