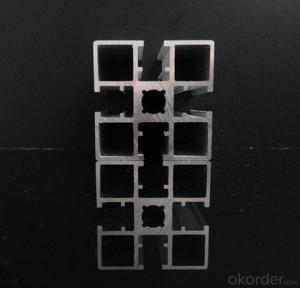

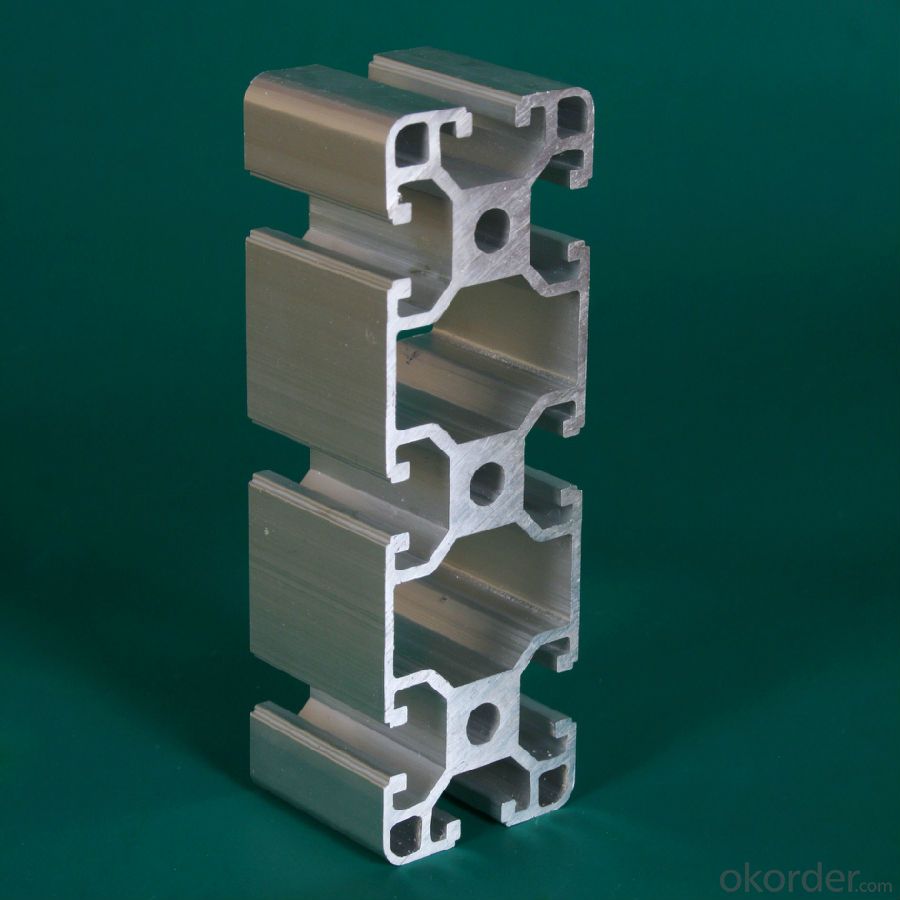

Customized Alloy 7075 Aluminum Extrusion Profiles for Industrial Applications

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Product Name | Alloy 7075 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: Are aluminum profiles suitable for bathroom fittings and accessories?

- Yes, aluminum profiles are suitable for bathroom fittings and accessories. Aluminum is a versatile material that is corrosion-resistant, lightweight, and durable, making it an ideal choice for bathroom fittings. Aluminum profiles can be used for various bathroom accessories such as towel racks, shower curtain rods, soap dispensers, and shelves. Additionally, aluminum can be easily shaped and molded into different designs and finishes, allowing for customization and aesthetic appeal. Its resistance to moisture and humidity also makes it a suitable choice for bathroom environments. Overall, aluminum profiles provide a practical and stylish solution for bathroom fittings and accessories.

- Q: What are the different shapes available for aluminum profiles?

- There are numerous shapes available for aluminum profiles, including but not limited to T-shapes, angles, channels, square tubes, rectangular tubes, round tubes, and custom profiles.

- Q: What are the different machining techniques used on aluminum profiles?

- Aluminum profiles can undergo various machining techniques to meet specific requirements and alter their shape. Some commonly used techniques are as follows: 1. Milling: By employing rotary cutters, material is removed from the aluminum profile to create slots, pockets, or contours on its surface. 2. Drilling: Holes are created in the aluminum profile, often for attaching fasteners or other components. 3. Turning: The aluminum profile is rotated while a cutting tool shapes and removes material, commonly used to create cylindrical shapes or eliminate excess material. 4. Grinding: An abrasive wheel is utilized to remove material from the surface of the aluminum profile, achieving a polished finish or eliminating imperfections. 5. Bending: Applying force to the aluminum profile allows for reshaping, resulting in curved or angled profiles. 6. Tapping: Internal threads are created in the aluminum profile, facilitating the screwing of fasteners. 7. Sawing: A saw blade is used to cut through the aluminum profile, often for specific length or shape requirements. 8. Welding: Aluminum profiles can be joined together through the application of heat and pressure, enabling the creation of complex structures or the combination of different profiles. These techniques represent only a few of the possibilities for machining aluminum profiles. The choice of technique depends on project requirements and desired outcomes.

- Q: How do aluminum profiles contribute to LEED certification?

- Aluminum profiles can contribute to LEED (Leadership in Energy and Environmental Design) certification in several ways. Firstly, aluminum is a highly sustainable material. It is one of the most abundant elements on Earth and can be easily recycled without losing its quality. Using aluminum profiles in construction projects reduces the demand for new raw materials, conserves energy, and minimizes greenhouse gas emissions. This aligns with LEED's focus on reducing the environmental impact of buildings. Additionally, aluminum profiles are lightweight yet durable, allowing for efficient transportation and installation. This can contribute to LEED points in the category of Sustainable Sites, which encourages the use of materials and techniques that minimize impacts on ecosystems and reduce pollution during construction. Furthermore, aluminum profiles can be used to improve energy efficiency in buildings. By incorporating thermal breaks and insulation, aluminum profiles can help prevent heat transfer and reduce energy consumption for heating or cooling. This can contribute to LEED points in the Energy and Atmosphere category, which promotes the use of energy-efficient systems and materials. Moreover, aluminum profiles are resistant to corrosion and require minimal maintenance over their lifespan. This durability can contribute to LEED points in the Materials and Resources category, which encourages the use of long-lasting, low-maintenance materials that minimize waste and the need for replacement. In conclusion, aluminum profiles contribute to LEED certification by promoting sustainability, reducing environmental impacts, improving energy efficiency, and enhancing the durability of buildings. By considering the use of aluminum profiles in construction projects, designers and builders can achieve LEED credits and contribute to a more sustainable future.

- Q: What are the different surface patterns or textures available for aluminum profiles?

- There are various surface patterns or textures available for aluminum profiles, including smooth, brushed, anodized, textured, embossed, and patterned finishes. These different finishes offer a range of aesthetic and functional options, allowing for customization and versatility in various applications.

- Q: How to distinguish the true and false of aluminum profile

- When you make the Fenglv aluminum material before installation, be sure to carefully observe the surface of profile, the existence of marks. If you were not allowed to see on the surface, you have the right to request processing and installation personnel to do a good job in the windows and doors, open a door or window frame, see section profiles in the middle of the inner wall, do surface spray treatment, which can not be sprayed to the section, so you see the color profile is not covered by the powder, so it is easy to if there is differential profile marks. There is no any authentic Feng streak lines. We recommend you to see when the processing requirements of installation personnel open a door or window frame observation you specify, in the absence of color powder surface observation, differential can easily pull!The main difference between true and false identification is the difference between Feng materials, the relevant logo really materials have Feng Feng, and point code; there is a difference in structure, but the average person is not easy to identify, is false is imitation Feng al Feng material, so it is not 100% imitation, so the fixed window is different, the line is not the same, this point without a careful comparison is not too much attention; and actually is not the same aluminum surface treatment, surface color really Feng wavy uniform, did not occur, but not because it is relatively poor in the local aluminum equipment under the electrostatic spraying, it is not possible to achieve the level of surface treatment of aluminum.Now due to the requirements of the color type is more, so the regular manufacturers have no choice except white, green, there is no aluminum Nanjing stock, so the manufacturer had to really change color when Feng, this situation is best to distinguish between true and false identification to the Al Feng Nanjing office.

- Q: What are the electrical insulation properties of aluminum profiles?

- Aluminum profiles have relatively low electrical insulation properties compared to other materials commonly used in electrical applications, such as plastics or ceramics. This is because aluminum is a highly conductive material, meaning it readily allows the flow of electrical current. However, aluminum profiles can still be used effectively in electrical applications if proper precautions are taken to ensure insulation. For example, aluminum profiles can be anodized or coated with insulating materials such as epoxy or polyurethane to improve their insulation properties. These coatings create a barrier between the aluminum and the electrical current, reducing the risk of electrical conductivity. Additionally, aluminum profiles can be used in conjunction with other insulating materials to provide the desired level of electrical insulation. For example, when used in electrical wiring systems, aluminum conductors are often combined with insulating materials such as PVC or cross-linked polyethylene to provide reliable insulation. It is important to note that while aluminum profiles may have lower electrical insulation properties compared to other materials, they do offer other desirable characteristics such as high strength, lightweight, and corrosion resistance. Therefore, careful consideration should be given to the specific application and electrical requirements before selecting aluminum profiles as an electrical insulation material.

- Q: Can aluminum profiles be used in material handling equipment manufacturing?

- Yes, aluminum profiles can be used in material handling equipment manufacturing. Aluminum profiles are lightweight, durable, and have excellent strength-to-weight ratio, making them suitable for constructing various components such as frames, supports, and conveyors in material handling equipment. Additionally, aluminum profiles offer versatility in terms of customization and can be easily assembled, making them a popular choice in this industry.

- Q: What are the environmental effects of utilizing aluminum profiles in the construction industry?

- <p>Yes, there are environmental impacts associated with using aluminum profiles in construction. Aluminum production is energy-intensive, which contributes to greenhouse gas emissions. However, aluminum is recyclable, and its recycling process requires significantly less energy than primary production, reducing environmental impact. Additionally, aluminum profiles are lightweight, which can reduce transportation emissions. Despite these benefits, concerns remain about the energy used in aluminum production and the potential for leaching of aluminum into the environment, which can affect soil and water quality.</p>

- Q: What are the weatherproofing properties of aluminum profiles?

- Aluminum profiles have excellent weatherproofing properties due to their inherent resistance to corrosion and their ability to withstand extreme weather conditions. They are highly durable and can effectively protect against moisture, UV radiation, and temperature fluctuations, making them ideal for outdoor applications. Additionally, aluminum profiles can be treated with various coatings or finishes to enhance their weather resistance even further.

Send your message to us

Customized Alloy 7075 Aluminum Extrusion Profiles for Industrial Applications

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords