Alloy 6061 Aluminium Extrusion Profiles For Industrial Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

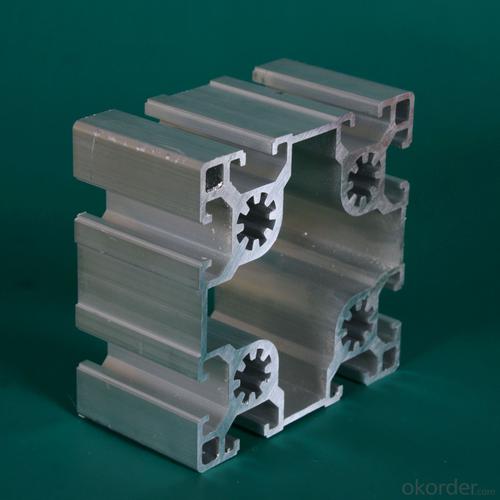

Product Name | Alloy 6061 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: What are the manufacturers of aluminum profiles in Jiangsu and Jiangyin?

- Jiangyin aluminum manufacturer, including aluminum, aluminum, cell Longding Xieji Xinyu aluminum, aluminum, aluminum, aluminum Donghua Jianbang started earlier, larger scale. Their market is mainly in East china.

- Q: What are the different machining options for aluminum profiles?

- For aluminum profiles, there are various machining options to choose from, depending on specific requirements and desired outcomes. Some commonly used machining options for aluminum profiles include: 1. Milling: By utilizing rotating cutting tools, material can be removed from the aluminum profile, resulting in intricate shapes and features. This versatile option is suitable for both roughing and finishing tasks. 2. Drilling: Holes can be created in aluminum profiles through drilling. The precision and accuracy required determine whether a conventional drill or a CNC machine is used. 3. Tapping: To enable secure fastening, internal threads can be created in aluminum profiles through tapping. This is commonly used with screws or bolts. 4. Turning: By rotating the aluminum profile and applying a cutting tool, cylindrical shapes or features can be created through turning. This method is often employed for precise round components like shafts or pins. 5. Sawing: Aluminum profiles can be cut to specific lengths or straight cuts can be made using a saw blade. This process is known as sawing. 6. Bending: To achieve the desired form, force is applied to reshape the aluminum profile through bending. Various methods, such as press brakes or roll forming machines, can be utilized for this purpose. 7. Grinding: For a smooth, polished finish or to remove imperfections, grinding involves using abrasive particles to eliminate small amounts of material from the surface of the aluminum profile. 8. Welding: Joining aluminum profiles is commonly done through welding. This process involves melting and fusing the aluminum profiles together using heat and pressure, resulting in a strong and durable bond. These examples highlight the range of machining options available for aluminum profiles. The choice of machining method depends on factors such as the desired shape, size, finish, and specific application requirements of the profile.

- Q: How do you ensure proper weatherproofing with aluminum profiles?

- To ensure proper weatherproofing with aluminum profiles, there are several key measures that can be taken. Firstly, it is important to select high-quality aluminum profiles that are specifically designed for weather resistance. These profiles should be treated with a suitable finish or coating that provides protection against corrosion and weather elements. Next, proper installation techniques should be followed to ensure a tight and secure fit. This includes ensuring that the profiles are correctly aligned and joined together using appropriate fasteners or adhesives. Any gaps or openings between the profiles should be sealed with weatherproofing materials such as silicone or rubber gaskets to prevent water or air infiltration. In addition, it is crucial to pay attention to the design and construction of the aluminum profiles. This involves incorporating features like sloped surfaces, drip edges, and drainage systems to facilitate water runoff and prevent pooling or accumulation. Adequate provisions should also be made to address thermal expansion and contraction, which can affect the weatherproofing performance of the profiles. Regular maintenance is another important aspect in ensuring long-lasting weatherproofing. Periodic inspections should be conducted to identify any signs of wear, damage, or deterioration in the profiles or their weatherproofing elements. Any issues should be promptly addressed through repairs or replacement to maintain the integrity of the weatherproofing system. Overall, by selecting quality aluminum profiles, following proper installation techniques, incorporating suitable design features, and conducting regular maintenance, one can ensure proper weatherproofing with aluminum profiles and enhance their durability and performance against weather elements.

- Q: How do aluminum profiles perform in vibration isolation applications?

- Aluminum profiles are highly effective in vibration isolation applications due to their unique properties and characteristics. The use of aluminum profiles in such applications helps to minimize and dampen vibrations, creating a stable and isolated environment. One of the primary reasons for the effectiveness of aluminum profiles in vibration isolation is their high strength-to-weight ratio. Aluminum is a lightweight material, which allows for the construction of structures that can effectively absorb and dissipate vibrations. This lightweight nature ensures that the profiles do not add excessive weight to the system, as added weight can amplify vibrations rather than dampen them. Additionally, aluminum profiles have excellent damping capabilities. Damping refers to the ability of a material to absorb and dissipate energy from vibrations. Aluminum possesses inherent damping properties, which significantly contribute to reducing vibration levels. This ensures that the profiles effectively isolate vibrations and prevent their transmission to other components or structures. Furthermore, aluminum profiles can be easily customized and designed to meet specific vibration isolation requirements. They can be engineered to have specific geometries and configurations, allowing for the creation of structures that effectively attenuate vibrations. This flexibility in design enables the optimization of the profiles for different applications and environments, ensuring maximum effectiveness in vibration isolation. Moreover, aluminum profiles offer good corrosion resistance, which is crucial in vibration isolation applications that may be exposed to harsh operating conditions. This corrosion resistance ensures the longevity and reliability of the profiles, maintaining their performance over extended periods. In summary, aluminum profiles are highly suitable for vibration isolation applications due to their lightweight nature, excellent damping capabilities, customization options, and corrosion resistance. Through their effective vibration absorption and dissipation properties, aluminum profiles help to create stable and isolated environments, minimizing the impact of vibrations on surrounding components or structures.

- Q: Aluminum profile spraying process

- Powder coating construction technology and requirements of the powder electrostatic spraying is the use of the principle of high voltage electrostatic corona electric field. With high-voltage anode in the gun head on the metal guide, is formed by spraying electrode of the workpiece, the formation of a strong electrostatic field between the gun and the workpiece. When the compressed air as carrier gas, powder coating from guide rod for powder barrels by powder pipe to spray gun, the corona discharge guide rod is connected with the high voltage anode is generated, and the negative charge density in the vicinity of the powder, with a negative charge, and entered into the field of electrostatic field strength is very high, in the dual role of static electricity and gas. The powder evenly ground to powder layer formed on the surface of workpiece thickness uniformity, and heat curing into durable coating coating construction process:

- Q: This question asks for the proper and safe method of installing aluminum profiles, which are commonly used in construction and manufacturing.

- <p>To install aluminum profiles correctly and safely, follow these steps: 1. Plan the layout and measure the required lengths accurately. 2. Use appropriate cutting tools to cut the profiles to size, ensuring a clean edge. 3. Apply protective gloves and eyewear when handling aluminum profiles to avoid injury. 4. Use the correct fasteners, such as screws or bolts, compatible with the aluminum profiles. 5. Ensure the profiles are securely fastened and aligned properly. 6. Check for any sharp edges or burrs after installation and smooth them out to prevent injury. 7. Always follow the manufacturer's guidelines and safety precautions. Proper installation and safety measures will ensure the longevity and stability of the aluminum profiles.</p>

- Q: Is it possible to tailor aluminum profiles to fulfill particular design and aesthetic needs?

- <p>Yes, aluminum profiles can be customized to meet specific aesthetic requirements. Manufacturers offer a variety of finishes, colors, and surface treatments to enhance the visual appeal of aluminum profiles. Additionally, the profiles can be cut, bent, and shaped to fit unique design specifications. This customization allows for a high degree of flexibility in creating structures and designs that are both functional and visually appealing, making aluminum profiles suitable for a wide range of applications from architectural to industrial design.</p>

- Q: This question asks for a description of the various dimensions and forms of aluminum profiles that are utilized in siding systems.

- <p>Aluminum profiles for siding systems come in a variety of sizes and shapes to accommodate different architectural styles and structural requirements. Common profiles include flat bars, channels, angles, and Z-profiles. Sizes can range from narrow trims of 10mm to wide panels of over 200mm in width, with thicknesses typically from 0.5mm to 3mm. Shapes are designed for specific functions, such as interlocking for a seamless appearance, or with grooves for attaching insulation. Custom profiles are also available for unique applications. These profiles are chosen based on the building's design, load-bearing needs, and aesthetic preferences.</p>

- Q: Will the aluminum profile be deformed at about 100 degrees?

- Of course, you only choose the quality of aluminum, as far as possible to choose the hardness of high bar, 5052, 5056, 6082, 7075 and so on are high strengthAluminium alloy。Our common 6063-T5 material, the door and window material is the material.

- Q: Where is the exact location? TwentyBecause I was doing aluminum sales, want to go to the market!Where is the specific market aluminum sales, as long as there is, I have to go around! Say where it is! For example, what area, what road, how many?! Since I went to Chengdu for the first time, please tell me more about it. Thank you!

- Two days ago in the city to find the north gate, Xinshengda profile market have taken a little more, Sammy, the gold house electrical city only one sell Aluminum Alloy, Wanguan electrical didn't go to see, tailor steel city to ask a security guard said little or no 512, no Aluminum Alloy sold, only 512 of the next street there is a Aluminum Alloy sell (416 opposite the hospital). Today I went to Qingbaijiang Fengxiang profile market. Where is the place where the aluminum alloy merchants gathered, the profiles, accessories, processing?...... Goods are available in all varieties。 But the aluminum doors and windows only home balcony with the majority, profile industry, such as steel rack chassis radiator with basically No. This market sells stainless steel materials, businesses are also more. Bus route Liang Jia lane to Qingbaijiang on the car, told the driver to Fengxiang market under the line, and 6 yuan fare, cheaper! Drive away the State Road 108 to Mi Mou Town, Fengxiang market in 108 State Road next great, far away saw. This is the latest information, 2013-9-12

Send your message to us

Alloy 6061 Aluminium Extrusion Profiles For Industrial Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords