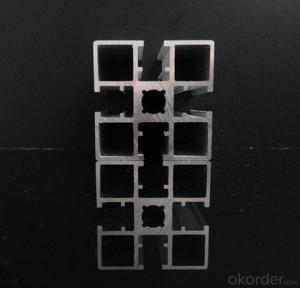

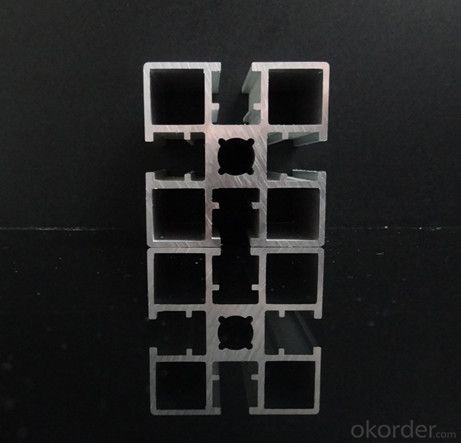

Custom Aluminum Profiles - Alloy 7005 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Product Name | Alloy 7005 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: How is the aluminum alloy profile series divided?

- According to alloy composition.1 pure aluminum, such as 1100,2 series aluminum alloy3 Series al Mn alloys, such as 3003, 3A214 series Al Si alloy5 Series Al Mg alloy6 series Al Mg Si alloy, such as 606360617 Series Al Zn Alloy8 lines, others9 line standby

- Q: Are aluminum profiles suitable for lighting fixtures?

- Lighting fixtures can greatly benefit from the use of aluminum profiles. Aluminum, being a lightweight and versatile material, offers numerous advantages for lighting applications. To begin with, aluminum profiles possess excellent thermal conductivity. This means they effectively dissipate the heat generated by the lighting fixtures. Maintaining a cooler operating temperature is crucial as excessive heat can shorten the lifespan and impact the performance of the lighting components. By utilizing aluminum profiles, the longevity and efficiency of the lighting fixtures are enhanced. Moreover, aluminum profiles are resistant to corrosion, making them suitable for both indoor and outdoor lighting fixtures. This corrosion resistance ensures that the fixtures can endure harsh environmental conditions, such as high humidity or moisture exposure, without deteriorating or losing functionality. Additionally, aluminum profiles are easily customizable and can be tailored to meet various lighting requirements. They can be extruded into different shapes and sizes, allowing for flexibility in the design of lighting fixtures. This versatility empowers manufacturers to create sleek and modern lighting solutions that seamlessly integrate into different architectural designs and spaces. Furthermore, aluminum profiles offer aesthetic appeal as they can be powder-coated or anodized in a wide array of colors. This provides a plethora of options to match different interior or exterior design themes. Lastly, aluminum is a sustainable material that can be fully recycled. By choosing aluminum profiles for lighting fixtures, one contributes to reducing environmental impact and supports the principles of sustainability. To summarize, aluminum profiles are highly suitable for lighting fixtures due to their thermal conductivity, corrosion resistance, versatility, aesthetic appeal, and sustainability. This is why they are extensively used in the lighting industry.

- Q: Can aluminum profiles be used for skylights?

- Yes, aluminum profiles can be used for skylights. Aluminum is a popular material choice for skylight frames due to its durability, strength, and resistance to corrosion. It is lightweight yet sturdy, making it suitable for supporting the weight of skylight glass while ensuring long-lasting performance. Additionally, aluminum profiles can be easily customized and shaped to meet specific design requirements, allowing for various skylight styles and sizes. The use of aluminum profiles in skylights also provides excellent thermal insulation properties, contributing to energy efficiency by reducing heat transfer and preventing condensation. Overall, aluminum profiles are a reliable and practical option for constructing skylights.

- Q: Xi'an XAC aluminum sales site.

- For the choice of aluminum profiles, here are a few suggestions for you to refer to:First: very cheap, do not chooseAs follows: the cost of industrial aluminum material = the spot price of aluminum ingot, the processing cost of extrusion aluminum material, the freight of packing material. These are transparent, the cost of aluminum profiles are similar, significantly lower than the market price, the first possibility: the weight per meter less; second: aluminum is the use of recycled materials; third: material loss amplification (not according to the actual sales amount of meters).Second: only understand the sale material supplier does not chooseExplain as follows: preparing goods, recruit a few operator, big online promotion can be opened. Those who are often hurt are our buyers. Miss wiring mostly do not know how to use, only know the unit price. How to use to meet customer needs; how to make the most cost-effective; in different venues that kind of connection is the best; these are they can not answer accurately. Only know the cheapest and recommended profile connection the cheapest; this connection is the lowest cost, but the cost of artificial, a connection is the weakest, aluminum convenience wouldn't be reflected, and will bring much trouble for the future reconstruction. But the wiring girl will push it one way.Third: in production of aluminium supplierExplain as follows: in the production of aluminum suppliers, are generally engaged in this industry for more than 10 years, and their users have very rich experience, have a good understanding and knowledge of the quality and performance of products, suitable for the requirement of the customers will recommend price is a good product, choose a convenient and practical accessories.

- Q: High compartment aluminum profiles are generally divided into several specifications, what are the attributes?

- Aluminum Alloy profiles are GB and non-standard, the state has special provisions on the thickness of the material, material requirements, each with the aluminum bar is not the same, we know that there are 6063-T5, A and aluminum and the B rods and even more, it shows a aluminum problem, raw materials and good poor relationship with out the quality of the materials, profiles of many kinds of Oh, high compartment aluminum, 80, paragraph 84 of paragraph 100, many Oh, don't be fooled that each kind of aluminum are the same, with the recovery of aluminum ingots is not the same as that of pure

- Q: This question asks if aluminum profiles can be utilized in sustainable construction projects and seeks an explanation of their application.

- <p>Yes, aluminum profiles can be used for green building projects. They are valued for their durability, recyclability, and energy efficiency. Aluminum profiles are lightweight, which reduces the load on structures and can contribute to energy savings in heating and cooling. They also have high thermal conductivity, which can be beneficial for heat transfer in building systems. Additionally, aluminum is 100% recyclable, meaning it can be repurposed without losing its properties, reducing waste and the need for new raw materials. This recyclability aligns with the principles of sustainable construction by promoting a circular economy and reducing the environmental impact of building materials.</p>

- Q: Can aluminum profiles be used in the production of consumer electronics?

- Consumer electronics production can make use of aluminum profiles, which possess qualities such as lightness, strength, and durability. These attributes render aluminum profiles appropriate for diverse purposes within the electronics sector. For instance, they can serve as housings or enclosures for smartphones, laptops, tablets, and audio equipment. The adaptability of aluminum profiles facilitates customization and seamless integration of components, guaranteeing optimal performance and safeguarding of electronic devices. Moreover, these profiles can undergo anodization or coating processes to acquire a polished appearance and increased resistance to corrosion. This further enhances their attractiveness in the realm of consumer electronics manufacturing.

- Q: How do you join two aluminum profiles together?

- There are several ways to join two aluminum profiles together, depending on the desired strength, appearance, and functionality of the joint. Here are a few common methods: 1. Mechanical Fasteners: One of the simplest and most common methods is to use mechanical fasteners such as screws, bolts, or rivets. These fasteners can be drilled through both profiles and tightened to securely hold them together. It is important to choose the appropriate size and type of fastener based on the thickness and material of the profiles. 2. Welding: Welding is another popular method for joining aluminum profiles. It involves melting the aluminum at the joint and allowing it to solidify, creating a strong bond between the two profiles. There are different types of welding techniques that can be used, such as TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding, depending on the specific application and requirements. 3. Adhesives: Adhesive bonding is a non-invasive method for joining aluminum profiles. Specialized adhesives designed for bonding aluminum can be applied to the surfaces of the profiles and then pressed together. This type of joint is particularly useful when a seamless appearance is desired, as it eliminates the need for visible fasteners or welds. However, the strength of the adhesive bond may vary depending on the type of adhesive used. 4. Interlocking Systems: Some aluminum profiles are designed with interlocking systems that allow them to connect easily. These systems typically involve the use of connectors or accessories specifically designed for the profiles being used. They can provide a secure and sturdy joint while also simplifying the assembly process. When deciding how to join two aluminum profiles together, it is important to consider factors such as the strength requirements, aesthetics, ease of assembly, and disassembly if necessary. Additionally, it is recommended to consult with professionals or experts in aluminum fabrication to ensure the chosen method is appropriate for the specific application.

- Q: This question is asking about the various types of aluminum profiles that are used for exterior cladding purposes.

- <p>Aluminum profiles for exterior cladding are diverse and serve various architectural and functional needs. Some common types include: 1. Flat Profiles: Used for simple, sleek designs. 2. Box Profiles: Ideal for creating a modern, industrial look. 3. Angle Profiles: Useful for corners and edges. 4. Channel Profiles: Often used for window and door frames. 5. T-Profiles: Commonly used for hidden fastening systems. 6. U-Channels: Suitable for cover applications. 7. Special Profiles: Custom designs for specific architectural requirements. Each type offers unique benefits in terms of aesthetics, strength, and weather resistance, making them suitable for different building facades and exterior applications.</p>

- Q: This question asks about the various methods for connecting aluminum profiles using fasteners.

- <p>There are several ways to join aluminum profiles together using fasteners: 1. Bolts and Nuts: Commonly used for strong and removable connections. 2. Rivets: Provide a permanent connection, suitable for high-stress applications. 3. Screws: Offer a secure and adjustable connection, often used in furniture and construction. 4. Pins: Used for alignment and positioning, often in lighter applications. 5. Adhesives: Can be used for a more aesthetically pleasing joint, though not as strong as mechanical fasteners. 6. Welding: Although not a fastener method, it is a common way to join aluminum profiles for a permanent and strong bond. Each method has its advantages and is chosen based on the specific requirements of the application, such as strength, permanence, and ease of assembly.</p>

Send your message to us

Custom Aluminum Profiles - Alloy 7005 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords