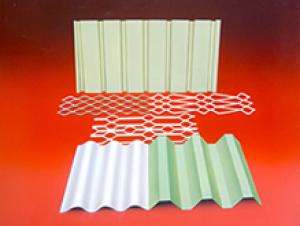

Aluminum Extrusion Heat Sink Profiles for Surface Treatment Aluminum Profiles for Windows and Doors

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: Everybody good: please look at this section of the aluminum can not buy ready-made standard parts. If the mold needs to be opened, is it the extrusion process? About how much is the die charge?. Thank you.

- Is it ready to estimate?. Custom mold. If the simple section of the mold is about two thousand yuan (our company has many of these profiles on the outside to buy), the mold fee is in a certain amount can be returned.

- Q: we recently entered a batch of aluminum billet, under the rain, billet oxidation, spray finished drawing after the profile off the skin, how to do

- Before treatment, not dealt with, must be dealt with before spraying, this situation.

- Q: Can aluminum profiles be used for solar power systems?

- Indeed, solar power systems can utilize aluminum profiles. The utilization of aluminum is widespread in the fabrication of solar panels and their supporting frameworks. Its lightweight characteristic, remarkable strength-to-weight ratio, and superior resistance to corrosion make it a favored material. Frequently employed for the framing and installation of solar panels, aluminum profiles offer both structural stability and enduring qualities. Notably, aluminum is effortlessly recyclable, rendering it an environmentally-conscious option for solar power systems.

- Q: How can I control the hardness of 6063 aluminum profile at 6-9 degrees?

- Two 、 soft burning treatment:2.1 purpose:Materials for stretching and stretching include rolling materials, extrusion materials and forging materials:Casting - Hot Processing - cold processing - finished materialIn the process of hot or cold processing processing, material processing hardening, the strength increases or lead to work hardening, the strength increases or lead to reduced processing. In order to eliminate the work hardening, for cold working before or after the application of heat treatment is soft burning treatment. Its purpose is to make use of the material is needed.2.2 classification:Due to the different conditions of soft burning:2.2.1 part of soft burning: only part of the work hardening is eliminated, the treatment temperature is below the recrystallization temperature, the actual temperature depends on the strength, and the higher the strength, the lower the treatment temperature2.2.2 completely soft burning: treatment temperature in the recrystallization temperature or slightly higher, so that the material recrystallization, and completely eliminate the work hardening, also make the strength to the lowest stateThere is time and soft burning:2.2.3 soft burning before cold or cold start process, soft burning treatment added, usually completely soft burning, its purpose in the recovery process, and make the next function more smoothly, and the control of the organization, in order to fit for the final product requirements.2.2.4 ultimate soft burning: the main purpose is to adjust the final strength level of the finished product, that is, to adjust the chain3 processing common sense

- Q: Can aluminum profiles be used for shelving systems?

- Yes, aluminum profiles can be used for shelving systems. Aluminum profiles are lightweight, durable, and have a high strength-to-weight ratio, making them suitable for supporting shelving units. Additionally, aluminum profiles can be easily customized and offer a sleek and modern aesthetic for shelving systems.

- Q: Are aluminum profiles compatible with other materials for construction purposes?

- <p>Yes, aluminum profiles can be used in combination with other materials in construction. They are often paired with steel, glass, and various plastics due to their lightweight, durability, and corrosion resistance. Aluminum's ability to be easily joined and its compatibility with different finishes make it a versatile choice for construction projects.</p>

- Q: How do aluminum profiles contribute to the reduction of carbon footprint?

- Aluminum profiles play a significant role in reducing carbon footprints due to their inherent environmental benefits. Firstly, aluminum is a highly recyclable material, with nearly 75% of all aluminum ever produced still in use today. This recyclability greatly reduces the need for extracting and refining new aluminum, which is an energy-intensive process that contributes to carbon emissions. Moreover, the lightweight nature of aluminum profiles provides several advantages in terms of transportation and energy consumption. As compared to other materials like steel, aluminum is significantly lighter, resulting in reduced fuel consumption during transportation. This not only reduces carbon emissions but also lowers the overall energy required for logistics. In addition, aluminum profiles are commonly used in the construction industry, where they contribute to the energy efficiency of buildings. Aluminum's excellent thermal conductivity enables the creation of highly efficient windows, doors, and facades, which prevent heat transfer and reduce the need for excessive heating or cooling. By improving the energy efficiency of buildings, aluminum profiles help to minimize energy consumption and consequently lower carbon emissions. Furthermore, aluminum profiles have a long lifespan and require minimal maintenance, which reduces the need for frequent replacement. This durability helps to conserve resources and reduces the carbon emissions associated with the production and disposal of alternative materials. Overall, the use of aluminum profiles in various industries contributes significantly to the reduction of carbon footprints. Its recyclability, lightweight nature, energy efficiency, and durability all make aluminum a sustainable choice with a positive impact on the environment.

- Q: Is it possible to utilize aluminum profiles as a component in systems designed for covering interior walls?

- <p>Yes, aluminum profiles can be used for interior wall cladding systems. They are lightweight, durable, and resistant to corrosion, making them an ideal choice for both residential and commercial applications. Aluminum profiles are easy to install and can be used in conjunction with various materials such as glass, stone, or wood to create a sleek and modern look. They are also customizable, allowing for a wide range of design options and can be powder-coated or anodized for different finishes and colors to match any interior design scheme.</p>

- Q: Are aluminum profiles suitable for playground equipment?

- Playground equipment can be made from aluminum profiles, which are lightweight and durable materials commonly used in many industries, including playground equipment manufacturing. These profiles are known for their strength and resistance to corrosion, making them perfect for outdoor use. They provide stability and can handle the weight and forces exerted during play. In addition, aluminum is non-toxic and does not rust, ensuring the safety and longevity of the equipment. The versatility of aluminum allows for the creation of various shapes and designs, offering endless possibilities for innovative and attractive playground structures. In summary, aluminum profiles are an ideal choice for playground equipment due to their strength, durability, and safety features.

- Q: What specific coatings or treatments are necessary for aluminum profiles to be used outdoors?

- <p>For outdoor use of aluminum profiles, special coatings or treatments are often required to protect against weathering, corrosion, and UV damage. Anodizing is a common process that increases the durability and resistance of aluminum. Powder coating is another method used for additional protection and to provide a wide range of colors. Some profiles may also be treated with a clear coat to maintain the natural look of aluminum while still offering protection. It's important to select the appropriate treatment based on the specific environmental conditions and aesthetic requirements of the application.</p>

Send your message to us

Aluminum Extrusion Heat Sink Profiles for Surface Treatment Aluminum Profiles for Windows and Doors

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords