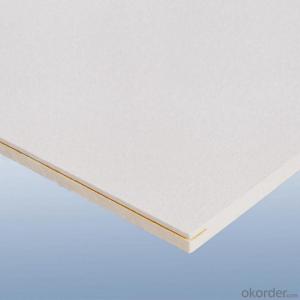

Fiberglass Under Deck Ceiling Panels 90k Density Acoustic Good Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Ceiling

The tiles are manufactured from high density fiberglass wool.The visible face has a decorative fiberglass tissue and the back of the tile is covered with normal tissue.The four edges of the tile are sealed and have grooves. It can be jointed together without suspended system. The tiles will cover the suspension system after installation. They are are suitable for loe flap ceiling space and concrete-made, wooded-made or gymsum ceiling.

Installation method:

Use screw to fix the smooth roof. The tiles can be connected after making grooves on each two jointed edges.

Tiles are easy to trim and install

Both inches and metric grids are available

Main Characteristic:

Non-combustible

No sagging,wrapping or delaminating

Green building material

Excellent sound absorption

Application:

Halls,classrooms,offices,shopping centers.etc.

Acoustic fiberglass ceiling contains a better perfomance in tension strong, light weight, so it is easy to trim and install for interior decoration, with T-grids for suspension system or glue, nail or good material could come with fiberglass ceiling baord. Thus an excellent artical work need a high quality acoustic ceiling board, also high quality.

Energysaving is a trend for our 21' era, new product like fiberglass ceiling tile could in place of traditional products one day. Which depends on functional characters: little deflection of geometry dimention, no radiocative property, specific activity of 226Ra: Ira ≤1.0 and specific activity of 226 Ra 232 Th, 40 K: Ir ≤ 1.3. Both products and packages can be recycled.

- Q: What is the use of Mgcl?

- Chemical Name: Magnesium Chloride [1] (MgCl2) Chemical Description: English name is magnesium chloride. Chemical formula MgCl2, is composed of 74.54% chlorine and 25.48% magnesium,

- Q: My house has not been renovated, according to the upstairs that he bought the best waterproof glue, do a number of waterproof treatment, try to see the water did not see a leak, told me to be assured! What is the possibility of future leakage? Thank you

- No matter he did not do waterproof, first told him to plug the hole, and looked uncomfortable. It is recommended to plug Wang Wang waterproofing agent mix a little sand, the effect is particularly good. Followed by good water, must be sure to personally do not leak, the best with the property management to participate in the acceptance, because the problem, property management and even the relationship. Tell the truth to see that hole, I doubt they can do waterproof.

- Q: Details: The house is a 3 story house. When showering on the 2nd or 3rd floor, the living room ceiling leaked. Not just 1-2 drops but we had to get a bucket and you can see the staining on the ceiling. This was 4-5 years ago and we stopped using these showers. No further leaking when NOT using the showers. The contractor opened the ceiling today near the staining and turned on the showers. He said that there was no leaking. What happened? Any suggestions? Thanks.

- Could you see any pipes in he ceiling, drain pipes or hot and cold water pipes? I doubt if the pipes fixed them selves and if you start using these showers again, it will start leaking again. Most likely the pipe or pipes have calcium deposit that have temporarily sealed the leak. I would leave the ceiling open for a week and use those showers every day to see if they start leaking again. Good luck

- Q: Fiberglass sound-absorbing ceiling features

- Substrate: dry glass fiber synthesis, high strength. Surface decoration: acrylic paint non-combustible properties

- Q: Hi Y/A, I have to repair some old ugly seams that have been patched badly, painted over twice and are now cracking as well, you know, where rooms are divided at the ceiling? What's the best way to clean those up without knocking them out and doing it <right> over? I have one, fairly long one..5 ft.

- it extremely is why you notice a super sort of ceilings with popcorn texture. The acoustic texture hides the failings. confident ceilings are greater solid reason you're working over head. you need to use a 12 vast knife on the seams. The topping compound could be a minimum of 12 or greater inches huge. this would feather out the seam. a superb dry wall-er would desire to try this authentic away and he does no longer cost you plenty. Spend some greater dollars and hire out, you already did the complicated area. good good fortune.

- Q: has any one used corrugated metal (used comonly on barn roofs and in resturant decor). for a ceiling in a basement. ( will be in bar-living-game open area) want to have access and hate drop ceilings. planning on just screwing to joist. would like to know if you are happy with and if you have any pictures.

- My best friends have a rustic country style decor and they've used corrugated metal ceilings in one bathroom and one bedroom--and they look fantastic! Both are painted, which I don't think you can do with that fiberglass stuff. Go for it. Theirs are also screwed to the joists.

- Q: What is the use of halogen powder

- 1, in the chemical industry is an important inorganic raw materials for the production of magnesium carbonate, magnesium hydroxide, magnesium oxide and other magnesium products, but also for the antifreeze and other raw materials. 2, in the metallurgical industry for the production of metal magnesium, liquid chlorine and high purity magnesia and so on. 3, in the building materials industry is the production of light building materials such as fiberglass, decorative panels, sanitary ware, ceilings, floor tiles, magnesium oxide cement, ventilation pipes, anti-theft covers, fire doors and windows, fire board, partition board, production of artificial marble High - rise building materials important raw materials. In the magnesite products can do high-quality magnesium tile, high-quality fire board, magnesium box, magnesium decoration plate, light wall panels, abrasive, stoves, fireworks and other additives. 4, in other areas can do food additives, protein coagulant, snow melting agent, refrigerant, dust, refractories and so on. With the brine (magnesium chloride aqueous solution) point of the tofu than the stone point of the tofu, soft and delicious 5. Metallurgical industry: used to manufacture refractory and pile furnace arm adhesive, and is the manufacture of flux and smelting metal magnesium Of raw materials. 6. Machinery industry: life, with lime soil can be made of mechanical crates, triangular mats and furniture, etc., is "soil material" good material. 7. Transportation industry: for the road ice melting agent, ice fast, less corrosive to the vehicle, higher than the effect of sodium chloride. 8. Medicine: made of magnesium chloride "halogen dry" can be used for medicinal purposes. 9. Agriculture: available for magnesium fertilizer, potassium and magnesium fertilizer and cotton defoliants

- Q: I have 100 acres of arable land, looking for partners and projects, interested friends to give an answer to it!

- Where? And then more to the better

- Q: We just remodeled and now have a family room in our basement. This is right under our upstairs living room. All noise in the basement comes directly upstairs. There is duct work running across the basement ceiling to the floor vents in the living room. We have nothing on the basement ceiling right now. Any suggestions of how to reduce the sound coming up? And no, getting rid of our kids is not an option!

- install insulation, and or a suspended ceiling...

- Q: What are the active lime use?

- First, the preparation of lime mortar and lime milk coating Lime mortar from lime paste and sand, water mixed together, can be used as the wall, the ceiling of the plaster. Lime milk is made from lime cream and is often used as a paint for interior and ceiling. Second, the preparation of lime and triad soil Lime: lime + clay. Triad: lime + clay + sand, stone or slag and other fillers. Can be widely used as the basis of the building, the road or the ground cushion. Third, the production of carbonized lime board The calcined lime board is a lightweight sheet made of ground lime, fibrous filler (such as glass fiber) or lightweight aggregate (such as slag), and then made by artificial carbonization. It is suitable for non-load bearing inner wall panel , Ceiling and so on. Fourth, the production of silicate products Grinding of lime or lime powder and sand or granulated blast furnace slag, slag, fly ash and other siliceous materials by ingredients, mixing, molding, and then pressure or high pressure steam curing, can be made of dense or porous silicate products The Such as lime sand bricks, fly ash bricks and blocks, aerated concrete blocks and so on. Fifth, the preparation of clinker-free cement Will have a certain activity of the material (such as granulated blast furnace slag, fly ash, coal gangue ash and other industrial waste), according to the appropriate proportion of lime with the common grinding, can be obtained with hydraulic cementing material, that is No clinker cement.

Send your message to us

Fiberglass Under Deck Ceiling Panels 90k Density Acoustic Good Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords