Fiberglass Suspended Ceiling Grid with Fiberglass Felt for Attractive Acoustics

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

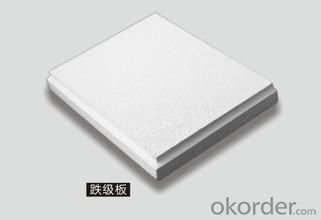

The tile is made by high-density fiberglass with compound decoration wool on the surface and fiberglass wool on the back .The edges are painted. With the characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The titles are manufactured from high density dry felf resin bonded fiberglass wool, with fine texture painted glass tissue facer,plain tissue backer and sealed and painted edges.square edge titles will be paralled to suspension system after installation.

Product Advantages:

1)Incombustibility/Non-flammability: Consmos Calcium silicate board is non-flammable and conforms to the national grade A standard (GB8624 Grade A) with excellent fire resistance property. In case of fire, the board will not burn and not give off toxic smoke.

(2)Thermal/heat insulation: Owing to low heat conductivity, the product has good performances on keeping warm and heat insulation.

(3)Water-proofing and moistureproof: The product is allowed to long-term exposure to moist environment but still very stable. The board still keeps intact after being soaked in water for one month, the phenomenon of swelling and out of shape will not happen. It has good adjusting mechanics like woods. Even it is used on wash house.

(4)Endurance/durability: Consmos Calcium silicate board provides good insulation against bugs, fungus and corrosion. It can last for a long time and will not corrode.

(5)Noise-proofing: Consmos Calcium silicate board provides good insulation against noise.

(6)High-Strength and Light weight: The board is light weight, in this case, it can decrease weight of building greatly. At the same time, the material is high-stength and not easy to be damaged.

(7)Easiness to installation: The construction process does not require complicated tools but just the ones used in regular wood construction. Our board can be fixed on light steel frame with self-attachable screws or a glue gun to nail the bolts into the wooden frame.

(8)Environmental protection: Consmos Calcium silicate board is 100% free of asbestos fiber and will not cause any harm to human body or the environment.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q: I kinda left the sink on while i was taking a shower.. so when i got out my bathroom floor had water everywhere (about an inch of water)i mopped up the mess with towels but i forgot to wipe inside the cabinets (and that what caused the water to soak through according to my mom) now i'm being screamed at every. single. day.on the first floor if you look up, the ceiling pretty much dried up but theres 2 creases popping out. kind of like a loong 3-d v shape since the water soaked through and outlined the cabinets shape.and since my mom loves burdening me soo much, now my parents say that they lost 5 grand in our house's value T____Ti don't know if we're supposed to repair it, paint over it (though u can't rlly paint over it), or w/e.. does anyone know what i should do? don't tell me to call a repair man because my parents want to see their 'options' before they call themThanks.. :)

- Peel away the loose and damaged surface. Get a container of 60 min sheetrock mud, fiberglass mesh tape and a trowel. Tape over the seams making sure the tape is IN the ceiling surface, put several coats (thin) on the ceiling, and then try to match the texture if you can. Paint over entire ceiling. This is what a contractor will do.

- Q: I have a 120 year old house w/ a flat roof, no attic and no insulation. I have a dropped ceiling on the top floor - drop is about 5&quot;. Ceiling tiles are not insulated. I plan on getting insulation and having it rest on top of the ceiling tiles.I live in Pittsburgh, PA where we get hot summers and cold winters. What would be a better insulation - traditional fiberglass or radiant? Radiant appeals to me since installation is easier, but if it won't be as effective, I won't do it. Thanks!

- get cellulose. fiberglass will melt in you have a fire, then your house will burn. cellulose while it is paper, will not burn. it has borax and other fire retardant things in it.

- Q: What is good material for external wall insulation

- Of course, is the use of fireproof materials rock wool board better

- Q: How is Sophia Wardrobe?

- Sophia Wardrobe advantage ? 1, ultra-high panel. Sofia can provide up to 2.8 meters of the door and side panels, wardrobe doors do not have splicing can be direct access to the ceiling, noble and elegant, extraordinary style. ? 2, two-color panels up to 10mm French original imported panel, woody strong, and both sides of different colors, can be used for face, more fashionable. ? 3, the unique top brush with nylon fiber material (steel products applicable), can be clever to keep the balance of the door guide, from the slowdown, to reduce the door back and forth collision is sliding sliding door system of high-tech. ? 4, choose to enrich a dozen independent sub-cabinet, a dozen wardrobe accessories, dozens of colors, any choice of free.

- Q: Indoor ground artificial marble paving after the bow is the reason

- Decorative materials are divided into two parts: part of the outdoor materials, part of the indoor materials.

- Q: We recently purchased a condo with an unfinished walkout basement. Two walls above grade have fiberglass batts with a plastic vapor barrier. The ceiling has exposed fiberglass batts. We have no immediate plans to finish the basement, but I will have a washer and dryer down there. There is an electric blower to keep the pipes from freezing, but no other source of heat. I am concerned about exposure to the fiber from the ceiling batts and am wondering if there is any covering I can use to encapsulate the fiberglass, or would removal be the best option? I heard that to cover in plastic would not be a good idea because of condensation. We live in a cold winter climate. Thank you.

- Short of a dropped ceiling, you might try stapling kraft paper or the such over the fiberglass. Lets the insulation breathe, but covers it up.

- Q: We just bought a house and our ceiling has the cottage cheese texture to it and it is cracked and broken in many placed so my husband wants to just take it off. I have told him that it may contain asbestos but he thinks he can do it on his own. So we are going to get it tested and if it does he just wants to remove it himself. My question is, is this a job anyone can do?

- As sparkles said asbestos is a hazardous materials.. wow if hubby wants to do it himself best of british luck. To start with he is going to need complete head mask and breathing gear filters and full overalls ,, no part of body to be exposed, the material has to be dampered as its pulled out and completely wrapped in plastic and taped up and buried with minimum cover of 6ft. Wash all clothes and then burn 'em You think I joke!! I kid you not.. asbestous dust can linger and if breathed in collects on the lungs then BINGO ..Asbestosis CANCER WITH A BIGGG C. Take it from someone who has it & i guarantee u dont want it.. So sit down with a glass of wine or beer , think about it and get the experts in you only have one life and the experts have the liscence to do it & get rid of it. Take the old man for a second honeymoon and leave it to them..... that's the best advice you can get for free. ciao.. but the fine if you get caught in Aussie land would NOTcompensate for the experts...

- Q: Hi,The felt (or whatever it is made of) ceiling in my car is falling down. I have scraped most of the residual glue off the ceiling made out of fiberglass and what I can off of the carpet/felt part. I've tried a couple of different types of two sided tape and can't get it to stick. Does anyone have any ideas?Thanks in advance...

- There is a headliner repair spray available at auto parts store. You spray it on the ceiling and the material your are trying to reattach, let it tack up, and then press into place. Works ok unless there is too much residual insulation on the ceiling.

- Q: Write a writing for the future

- Look at some science fiction may help but do not look addicted

- Q: Plywood on the first scraping ash, and then scraping 821 putty sticky prison it?

- Wood joint processing. Construction of the base surface according to the actual situation to determine whether to spray observation, ceilings are wooden ceiling, to use plate (ceilings) filling agent for caulking, with kraft paper or fiberglass mesh covered flattened, filling agent dry into the process

Send your message to us

Fiberglass Suspended Ceiling Grid with Fiberglass Felt for Attractive Acoustics

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords