8 1 2 X 11 Sheets Aluminum for Ink Jet - Aluminium Sheet 1050 1060 1100 3003 with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.2~320mm |

Width | <2800mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Payment | L/C ,T/T |

Brief Introduction for Cold Rolled Steel Coil

Cold Rolled Steel Coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold Rolled Steel Coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The Cold Rolled Steel Coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the Cold Rolled Steel Coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final Cold Rolled Steel Coil may be manufactured in the form of sheets, strips, bars, or other forms.

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

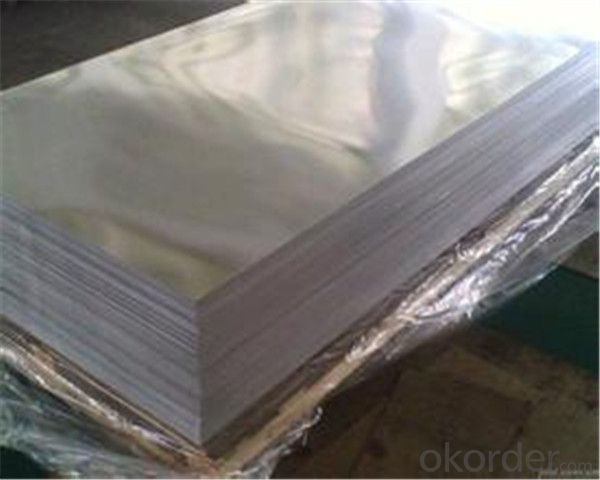

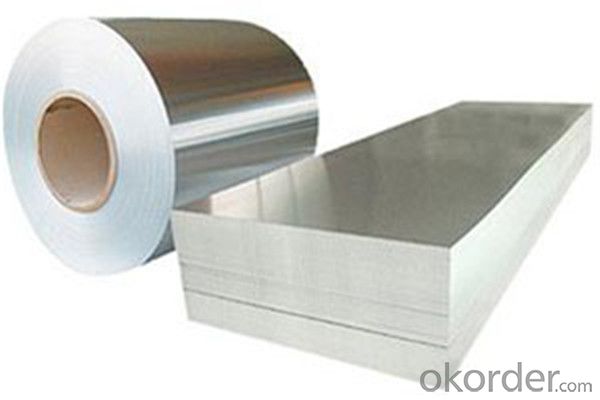

Photos of products

If you were to take a quick look around the room you're currently sitting in, it's likely that you would be able to name a number of objects that have been made using aluminium. This metal is one of the most popular on earth and, as such, it has a number of applications that feature in our daily lives. One of the best applications for aluminium today is as a roofing material, and here are the reasons why:

Leaks

This is something that all homeowners would like to avoid at all costs, as leaks can cause considerable damage to the structural integrity of a building, not to mention ruin paint jobs and carpet. Fortunately, aluminium roofing can be installed at varying pitches whilst still providing adequate water run off. The next time there's a torrential downpour, you won't have to fear flooding.

Flammable

Another concern for homeowners is how their property will be able to withstand a fire, should one ever break out. This is an area in which aluminium roofing is truly given the chance to shine. Unlike other roofing materials, this metal is not flammable in the slightest and will not be coated with substances that could catch fire. This makes aluminium an extremely safe choice.

Cost

Whilst there are some arguments that suggest aluminium roofing costs more than most other types, you cannot deny the benefits that such a choice will provide your home with. Even so, purchasing sheets of corrugated aluminium can actually work out to be a very cost effective way of providing your home and possessions with protection.

Lightweight

The need to repair or replaced sections of the roof can strike fear into the hearts of many homeowners, simply for the fact that they dread having to haul a bunch of tiles up the side of the house. With aluminium roofing, on the other hand, you will be able to handle the sheets much easier and won't risk falling off the roof simply getting them up there.

With all of the advantages offered to you and your home with the inclusion of aluminium roofing, it's any wonder that more buildings haven't been fitted with this fantastic material. If you are in the process of renovating or building your home and have been on the lookout for a suitable roofing material, you really should be looking into aluminium for the fact that is lessens the chances of leaks and is not flammable.

- Q: What are the limitations of using aluminum sheet?

- There are several limitations to using aluminum sheet. Firstly, it has a lower strength-to-weight ratio compared to other materials like steel. This means that aluminum sheets may not be as strong and durable in certain applications. Additionally, aluminum is prone to corrosion, especially in harsh environments, so proper protective coatings or treatments are necessary. Aluminum sheets also have limited formability compared to materials like steel, which can impact their use in certain complex shapes or designs. Lastly, aluminum sheets can be more expensive than other materials, which may affect their affordability in certain projects.

- Q: This question asks about the various types of aluminum sheets that are commonly used for roofing purposes, including their specific applications and characteristics.

- <p>Aluminum sheets used for roofing come in various types, each with unique properties and applications. The main types include: 1) Corrugated Aluminum Sheets: Known for their strength and durability, these are often used in commercial and industrial roofing due to their ability to withstand harsh weather conditions. 2) Standing Seam Aluminum Sheets: These provide a sleek, clean look and are favored for their water-resistant properties, making them ideal for residential and architectural applications. 3) Flat Aluminum Sheets: Offer a smooth surface finish and are used where a uniform appearance is desired. 4) Perforated Aluminum Sheets: These have small holes that allow for ventilation, reducing heat build-up and are used in areas requiring natural light and air circulation. 5) Embossed Aluminum Sheets: With a textured surface, they provide added rigidity and are used in both residential and commercial settings for their aesthetic appeal. Each type is chosen based on the specific needs of the roofing project, such as design, weather resistance, and longevity.</p>

- Q: This question asks for methods to preserve the aesthetic quality of aluminum sheets and prevent deterioration over time.

- <p>To maintain the appearance of aluminum sheets over time, follow these steps: 1. Regularly clean the sheets with a mild detergent and water to remove dirt and grime. 2. Avoid using harsh chemicals or abrasive materials that can scratch the surface. 3. Apply a protective coating or sealant if the sheets are exposed to harsh weather conditions or corrosive environments. 4. Inspect the sheets periodically for signs of corrosion or damage and address any issues promptly. 5. Keep the aluminum sheets dry, as moisture can lead to rust and other forms of deterioration. Proper maintenance will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: I have been doing this science prac at school and I have received some strange results. I measured the density of this metal, which leads me to believe it is Aluminium. Also, its silvery appearance supports this. When I have attempted to react it with Hydrochloric Acid, Sulfuric Acid and the nitrates/chlorides of a few metals, I have received some odd results.Despite having a high reactivity, the only substance it has reacted with so far out of all of the above is Tin Chloride. Am I doing something wrong? Is it possible that it isn't aluminium and rather a similar metal such as zinc? Thanks in advance :)

- Aluminum is very reactive so what happens is that it has a coat aluminum oxide as soon as it comes in contact with oxygen the outer layer forms aluminum oxide Al2O3. That is why Aluminum does not rust. The Al203 coat protects it.

- Q: Can aluminum sheet be used for heat shielding?

- Yes, aluminum sheet can be used for heat shielding due to its high thermal conductivity and ability to reflect and radiate heat effectively.

- Q: What are the different types of alloys used for painted aluminum sheets?

- Painted aluminum sheets commonly utilize various types of alloys. Among them, 3003 stands out as a favored option due to its exceptional corrosion resistance and high formability. This alloy finds extensive use in industries like automotive, where a smooth surface finish is preferred. Another frequently employed alloy is 5052, which provides superior strength compared to 3003. Its remarkable resistance to corrosion and ability to endure harsh environments make it suitable for marine and architectural applications. Moreover, it is renowned for its weldability and formability. 6061 is also a well-liked choice for painted aluminum sheets. Its notable attributes include high strength and excellent machinability. This alloy is often employed in structural applications, such as the production of aircraft parts and automotive components. Furthermore, painted aluminum sheets may incorporate other alloys like 2024, 5754, and 7075. These alloys possess specific properties that render them suitable for particular applications, such as elevated strength or improved corrosion resistance. In essence, the selection of the alloy for painted aluminum sheets hinges upon the specific requirements of the application, such as desired strength, corrosion resistance, and formability.

- Q: What is the fatigue strength of 101 aluminum sheets?

- The fatigue strength of 101 aluminum sheets refers to the maximum stress level that the sheets can endure without experiencing fatigue failure. The fatigue strength of a material is typically determined through fatigue testing, where the material is subjected to repeated cyclic loading until failure occurs. However, it is important to note that the fatigue strength can vary depending on a range of factors such as the sheet's thickness, surface condition, heat treatment, and other mechanical properties. Therefore, without specific information on these variables, it is not possible to provide an accurate value for the fatigue strength of 101 aluminum sheets. To determine the fatigue strength of 101 aluminum sheets, it is recommended to consult the material's technical datasheet or reach out to the manufacturer or supplier for specific information. They can provide details on the fatigue properties, including the endurance limit or the stress level at which the material can withstand an unlimited number of cycles without fatigue failure.

- Q: What type of aluminium sheet is a food grade?

- You can inquire about our company: dexincheng Pioneer Metals corporation. Baidu will find the phone soon.

- Q: What is the typical fracture toughness of aluminum sheets?

- The typical fracture toughness of aluminum sheets can vary depending on a variety of factors such as the alloy composition, heat treatment, and manufacturing process. However, on average, the fracture toughness of aluminum sheets ranges from 20 to 40 MPa√m. This value indicates the material's ability to resist crack propagation and withstand applied loads without fracturing. It is worth noting that aluminum alloys can be further enhanced with various strengthening techniques, such as alloying elements and grain refinement, which can improve their fracture toughness. Therefore, it is essential to consider specific aluminum alloys and their respective processing conditions to determine the precise fracture toughness of aluminum sheets in a given application.

- Q: Can aluminum sheets be used for chemical reactors?

- Yes, aluminum sheets can be used for chemical reactors. Aluminum is often chosen for its corrosion resistance, lightweight properties, and ability to withstand high temperatures, making it suitable for various chemical processes in reactor applications. However, it is important to consider the specific chemical reactions and conditions involved, as certain chemicals or extreme conditions may chemically react with or degrade aluminum.

Send your message to us

8 1 2 X 11 Sheets Aluminum for Ink Jet - Aluminium Sheet 1050 1060 1100 3003 with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords