5086 Aluminum Sheets - Polyester Coated Aluminum Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Polyester Coated Aluminum Coil for Construction Description:

Color coated aluminum coil is aluminum coil after cleaning, coating, and baking. Surface of aluminum coil can be painted to any color. Dong Chuan color-coated aluminum coil and aluminum sheet coils mainly come from Southwest Aluminum, Nanping, Chinalco, Ruimin, etc. which are the best raw materials suppliers domestically. Our coating paints are mainly from American PPG and Swedish Becker.

2.Main Features of Polyester Coated Aluminum Coil for Construction:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

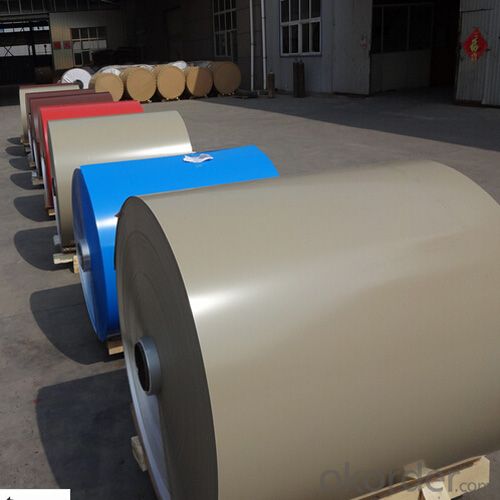

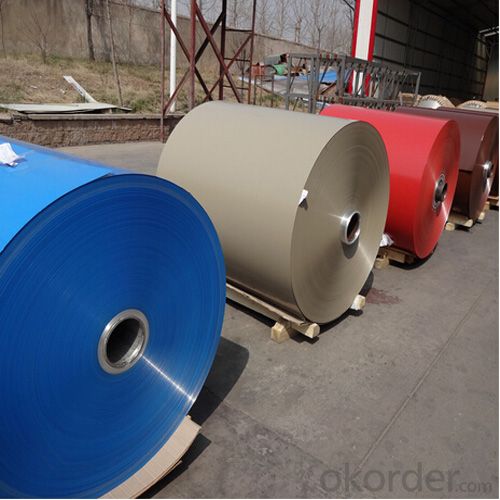

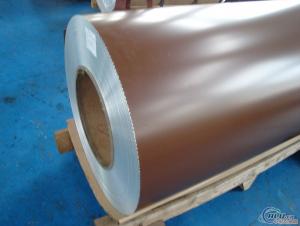

3. Polyester Coated Aluminum Coil for Construction Images:

4. Polyester Coated Aluminum Coil for Construction Specification:

Item | Color Coated Aluminium coil,Aluminium coil,Aluminium alloy coil, |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc |

Material | 1060,1050,1070,1100,a1100P,3003,3005,5052,5652,5154,5254,5454,5083,5754, 5086,5056,5456,2A12,2024,2014,6061,6062,6063,6082,7003,7004,7075,8010,8020,etc |

Thickness | 0.1-200mm |

Width | 10-2600mm |

Length | 1-12m,or as required |

Temper | 0-H112,T3-T8,T351-T851 |

Surface | mill,bright,polished,hair line,brush,sand blast,checkered,embossed,etching,etc |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What is the coefficient of expansion for aluminum sheets?

- The coefficient of expansion for aluminum sheets is roughly 0.000022 per degree Celsius, indicating that the aluminum sheet will expand by 0.000022 times its original length with every degree Celsius rise in temperature. It is crucial to take this coefficient of expansion into account in situations where the aluminum sheets may encounter fluctuating temperatures, as it can impact the material's overall dimensions and stability.

- Q: How do aluminum sheets perform in terms of dimensional stability?

- Aluminum sheets generally exhibit good dimensional stability due to their low coefficient of thermal expansion, meaning they are less likely to warp or deform when exposed to temperature changes compared to other materials.

- Q: Are aluminum sheets suitable for chemical storage applications?

- Yes, aluminum sheets are suitable for chemical storage applications. Aluminum is known for its excellent corrosion resistance, making it ideal for storing a wide range of chemicals. It forms a naturally occurring oxide layer on its surface, which provides a protective barrier against moisture and chemicals. Additionally, aluminum sheets are lightweight and easy to handle, making them convenient for storage purposes. However, it is essential to consider the specific chemical being stored and consult with experts to ensure compatibility with aluminum. Some highly corrosive or reactive chemicals may require alternative storage materials.

- Q: Can aluminum sheets be bent without cracking?

- Yes, aluminum sheets can be bent without cracking, as long as the bending process is done carefully and within the material's limits.

- Q: I have tried every possible method that I could find on the web for cleaning aluminum, tungsten, filler wire. Nothing has seemed to work. I've tried looking for leaks in the argon line. I'm getting decent welds but there is gunk in the welds for sure. I'm worried about overall strength of the welds. Does anybody out there know of a tried and true method for cleaning aluminum, tungsten, filler etc. that is sure to work? If I can follow that method and still have problems It could possibly be a problem with the machine. Any help would be much appreciated.

- Preweld cleaning requires two operations: oil/grease removal and oxide removal. As below, remove oils and greases first, then remove the oxide. Don’t reverse this order. Take the following steps before welding aluminum: 1. Remove oil, grease, and water vapor using an organic solvent such as acetone or a mild alkaline solution like a strong soap. You may also use citrus-based degreasers, but be sure to rinse and dry the part before welding. 2. Remove surface oxides with a stainless steel wire brush (used only for aluminum) or strong alkaline or acid. Many welding suppliers sell oxide-removal solutions in spray or squeeze bottles for local application. Exercise extreme care when handling these solutions, and again, rinse and dry the part before welding. 3. Assemble the joint. If it won't be welded immediately, cover the joint with brown Kraft paper to prevent dirt and grit in the air from getting into the joint. 4. Keep the aluminum dry and at room temperature. 5. Weld within a few days. Clean the joint again if it isn't welded within that time. Good luck!!!

- Q: What are the different methods of cutting aluminum sheet?

- There are several methods of cutting aluminum sheet, each with its own advantages and applications. 1. Shearing: This is a straightforward method that involves using a sharp blade to cut through the aluminum sheet. It is a fast and efficient process, especially for straight cuts. However, it may not be suitable for complex or intricate designs. 2. Laser cutting: Laser cutting utilizes a high-powered laser beam to melt or vaporize the aluminum sheet, resulting in a precise and clean cut. This method is ideal for intricate designs, as it allows for detailed and accurate cuts. Laser cutting is also fast and can be automated, making it suitable for large-scale production. 3. Waterjet cutting: Waterjet cutting involves using a high-pressure stream of water mixed with abrasive materials to cut through the aluminum sheet. This method is versatile and can handle different materials and thicknesses. It produces a smooth and precise cut without generating heat, making it suitable for heat-sensitive materials. 4. Plasma cutting: Plasma cutting involves using a plasma torch to heat and melt the aluminum sheet, creating a cut. It is a fast and cost-effective method, especially for thicker sheets. However, the cut might not be as clean compared to laser or waterjet cutting. 5. CNC milling: Computer Numerical Control (CNC) milling involves using a rotating cutting tool to remove material from the aluminum sheet, creating a cut. This method is precise and can produce complex shapes and designs. It is commonly used for prototypes or small production runs. It is important to consider factors such as the desired cut quality, complexity of the design, material thickness, and production volume when choosing the appropriate method for cutting aluminum sheet.

- Q: What are the different methods of surface engraving aluminum sheets?

- There are several methods of surface engraving aluminum sheets, including laser engraving, mechanical engraving, chemical etching, and diamond drag engraving. Each method offers different levels of precision and depth, allowing for various artistic or functional purposes.

- Q: Are the aluminum sheets suitable for manufacturing power distribution panels?

- Yes, aluminum sheets are suitable for manufacturing power distribution panels. Aluminum is a lightweight, durable, and corrosion-resistant material that makes it an ideal choice for various industrial applications, including power distribution panels. Aluminum sheets can withstand high electrical currents while effectively dissipating heat, ensuring the safe and efficient distribution of power. Additionally, aluminum is readily available and cost-effective compared to other materials such as copper. Therefore, aluminum sheets are a suitable choice for manufacturing power distribution panels.

- Q: What is the typical lead time for ordering aluminum sheets?

- The typical lead time for ordering aluminum sheets can vary depending on the supplier and specific requirements, but it usually ranges from a few days to a couple of weeks.

- Q: Are 101 aluminum sheets suitable for aerospace tooling?

- No, 101 aluminum sheets are not suitable for aerospace tooling.

Send your message to us

5086 Aluminum Sheets - Polyester Coated Aluminum Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords