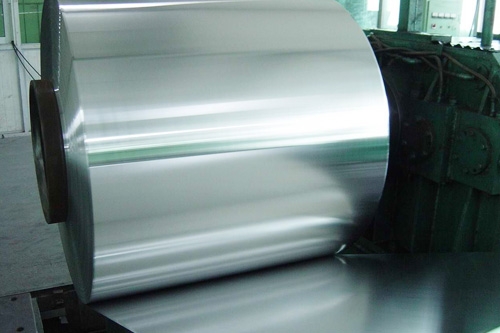

Large Aluminum Sheets for Sale - Cold Rolled & Hot Rolled Aluminum Coil and Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet and hot rolled sheet are all widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,7075,,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

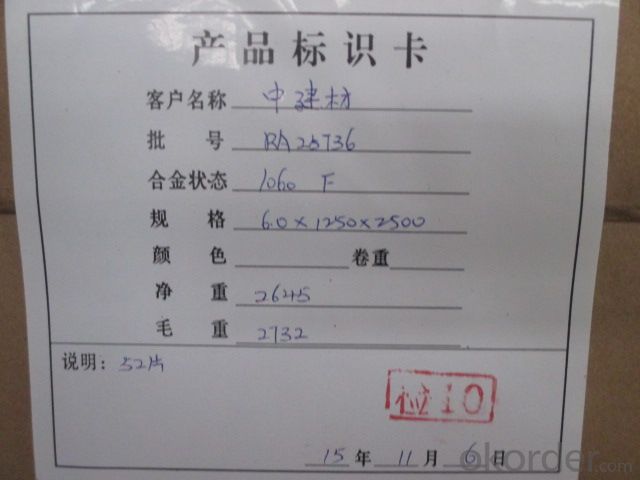

4. Product detailed sizes:

1000mm*2000mm, 1219mm**2440mm, 1250mm*2500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, vietnam, sri lanka, bangladesh, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are hot rolled sheet and cold rolled sheet,

aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Yes, aluminum sheets are suitable for use in food processing and packaging industries. Aluminum is a versatile and widely used material in the food industry due to its excellent properties and advantages. Firstly, aluminum is a non-toxic material, making it safe for direct contact with food. It does not react with food or alter its taste, ensuring the preservation of the original flavor and quality. This is particularly important in the packaging industry, as it helps to maintain the freshness and integrity of the food product. Secondly, aluminum has excellent thermal conductivity, which allows for efficient and even heat distribution during food processing. This property is beneficial for cooking, baking, and other thermal processes, ensuring that food is cooked or processed evenly. Additionally, aluminum sheets offer excellent barrier properties, such as resistance to moisture, light, and gases. This helps to protect food from external factors that could potentially deteriorate its quality, such as moisture or oxygen. It also helps to prolong the shelf life of packaged food products. Furthermore, aluminum sheets are lightweight, yet strong and durable. This makes them easy to handle and transport in food processing and packaging operations. Their strength and durability ensure that the packaging remains intact and protects the food during transportation and storage. Lastly, aluminum is a sustainable material. It is 100% recyclable, meaning that it can be reused without losing its properties. This helps to reduce the environmental impact and supports the circular economy. In conclusion, aluminum sheets are highly suitable for use in the food processing and packaging industries. Their non-toxic nature, thermal conductivity, barrier properties, lightweight yet strong characteristics, and sustainability make them an ideal choice for ensuring the safety and quality of food products.

- Q: This question asks for the cost of an aluminum sheet.

- <p>The cost of aluminum sheets can vary significantly based on factors such as thickness, grade, surface finish, and market conditions. As of my last update, the price range for aluminum sheets could be anywhere from $0.50 to $5 per pound, but this is subject to change. For the most accurate and current pricing, it's best to check with suppliers or on metal exchange platforms, as prices can fluctuate daily. Always consider the specific requirements of your project to determine the exact type and grade of aluminum needed, which will also affect the cost.</p>

- Q: This question asks about the various colors and finishes that can be applied to aluminum sheets.

- <p>Aluminum sheets are available in a wide range of colors and finishes, offering versatility for various applications. Common colors include silver, white, black, and bronze, but they can also be anodized or painted to achieve virtually any color. Finishes can be smooth, brushed, or embossed, with options like matte, satin, and gloss. Additionally, there are specialty finishes like mirror-like polished, hammered, and wood grain textures. The choice of color and finish depends on the specific requirements of the project, such as aesthetics, durability, and resistance to environmental factors.</p>

- Q: This question asks for a comparison of aluminum sheets with other common materials used in building insulation, focusing on their properties and performance.

- <p>Aluminum sheets are lightweight and have excellent thermal conductivity, which can be both an advantage and a disadvantage in insulation. They reflect heat well, making them useful in radiant barrier applications, but they are poor insulators as they do not trap heat. In contrast, materials like fiberglass, cellulose, and mineral wool have lower thermal conductivity and are more effective at reducing heat transfer. These materials are better at insulating as they trap air, which is a poor conductor of heat. Foam insulation, such as polyurethane and polystyrene, also offers good thermal resistance due to their closed-cell structure. Overall, aluminum sheets are not typically used as primary insulation but can be effective in specific applications where heat reflection is desired.</p>

- Q: Can 101 aluminum sheets be CNC machined?

- CNC machining is capable of processing 101 aluminum sheets, allowing for the creation of intricate and accurate cuts, holes, and shapes. This versatile and precise manufacturing process is commonly employed for aluminum materials. It involves computer-controlled machines that remove material from the sheets. The CNC machinability of 101 aluminum sheets is not restricted by their specific alloy designation. Nevertheless, to achieve optimal results, it is crucial to take into account factors like cutting parameters, tool selection, and feed rates when machining these sheets.

- Q: What precautions should be taken to ensure safety while installing aluminum sheets?

- <p>When installing aluminum sheets, safety measures include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hard hats. Ensure the work area is clear of debris and any tripping hazards. Use ladders and scaffolding that are in good condition and set up correctly. Always have a spotter when lifting heavy sheets and use proper lifting techniques to avoid back injuries. Keep hands and feet away from edges and corners to prevent cuts. Ensure all tools are in good working order and use them correctly. Follow all manufacturer's guidelines for installation and adhere to local safety regulations.</p>

- Q: What are the common sizes of aluminum sheets?

- The common sizes of aluminum sheets vary, but some of the standard sizes include 4x8 feet, 4x10 feet, and 5x10 feet. These sizes are widely available and commonly used in various industries.

- Q: Can aluminum sheet be used for automotive body panels?

- Automotive body panels can indeed utilize aluminum sheets. In fact, aluminum is gaining popularity in the automotive industry due to its numerous advantages. Firstly, aluminum surpasses steel in terms of weight, leading to improved fuel efficiency and overall vehicle performance. Furthermore, aluminum boasts high resistance to corrosion, providing durability for body panels exposed to the elements. Additionally, aluminum exhibits remarkable formability, enabling the creation of intricate designs and enhancing design flexibility during vehicle production. Moreover, aluminum excels in absorbing crash impact, thereby enhancing vehicle safety. Nevertheless, it is important to acknowledge that utilizing aluminum for automotive body panels may necessitate specialized equipment and techniques for welding and repair purposes.

- Q: is putting Aluminium foil behind the wind shield actually generate more heat and make the car hotter inside or make the car inside cooler? assume you put foil behind all windows.

- it does it is just too thin to hold the heat once the heat source has been removed

- Q: Are aluminum sheets conductive?

- Indeed, aluminum sheets possess conductivity. Being a metal, aluminum exhibits exceptional electrical conductivity. Consequently, aluminum sheets facilitate the smooth passage of electricity, rendering them suitable for an array of applications that necessitate conductivity, including electrical wiring, power transmission lines, and electronic devices.

Send your message to us

Large Aluminum Sheets for Sale - Cold Rolled & Hot Rolled Aluminum Coil and Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords