5052 Aluminum Sheets for Sale - Direct Casting Aluminium Coils for Secondary Rolling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

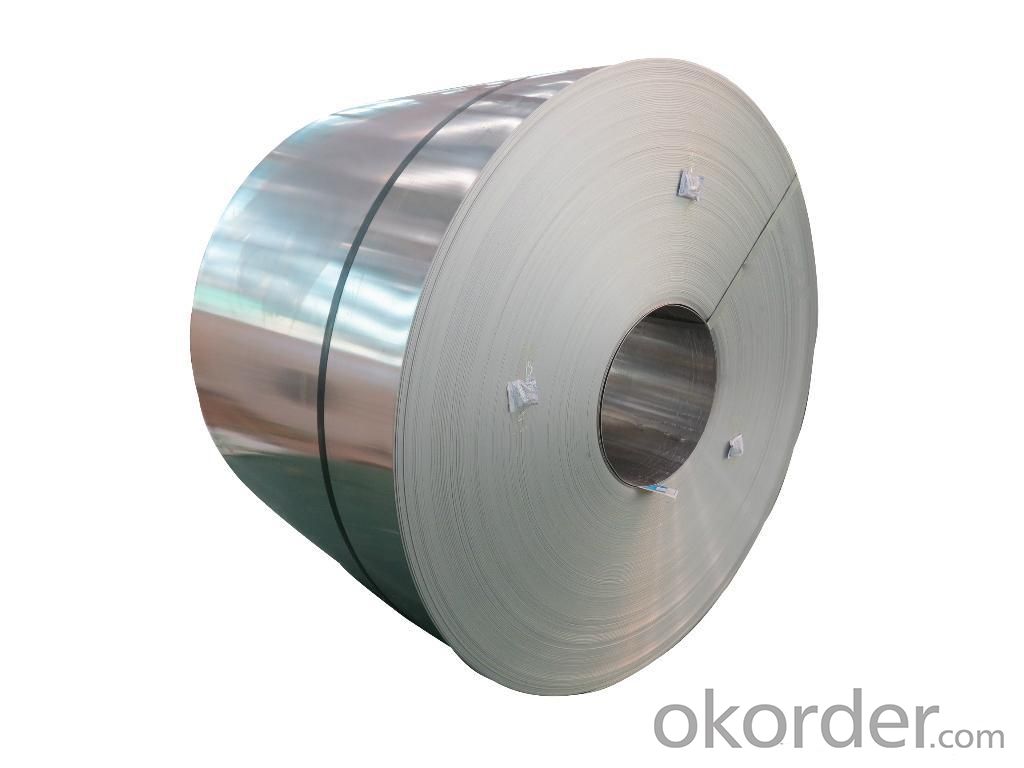

1.Structure of Direct Casting Aluminium Coils for Secondary Rolling

Direct Casting Aluminium Coils for Secondary Rolling in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Direct Casting Aluminium Coils for Secondary Rolling

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | TEMPER | THICKNESS | WIDTH | WEIGHT |

| AA5052 | H14 | 3MM-8MM | 1200MM-1800MM | 5-6 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: is there aluminum oxide on the surface of aluminum sheet after being polished by abrasive paper?

- aluminum will be oxided as aluminum oxide once being exposed in air.

- Q: What are the different methods of surface protection for outdoor aluminum sheet?

- There are several methods of surface protection for outdoor aluminum sheets. One common method is painting the surface with a protective coating, such as a weather-resistant paint or powder coating. Another method is anodizing, which involves creating a durable oxide layer on the surface of the aluminum. Additionally, applying a clear protective film or using a protective sealant can also help protect the aluminum sheet from outdoor elements.

- Q: Can aluminum sheets replace traditional roofing materials such as wood or metal?

- <p>Yes, aluminum sheets can be used as an alternative to traditional wooden or metal roofing. They offer several advantages, including resistance to corrosion, lightweight nature, and durability. Aluminum is also recyclable and can be painted or coated to provide a long-lasting finish. However, it's important to consider factors such as cost, local climate, and the specific requirements of the building project when deciding whether to use aluminum sheets for roofing.</p>

- Q: What are the potential environmental issues that arise from the use of aluminum sheets?

- <p>Yes, there are environmental concerns related to using aluminum sheets. The production process is energy-intensive and contributes to greenhouse gas emissions. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The disposal of aluminum waste can also lead to pollution if not properly managed. However, aluminum is highly recyclable, which can mitigate some of these concerns if recycling practices are adopted widely.</p>

- Q: This question asks for a comparison of aluminum sheets with other materials regarding their cost and performance.

- <p>Aluminum sheets are generally cost-effective and offer excellent performance compared to many other materials. They are lightweight, which reduces material and transportation costs. They also have high strength-to-weight ratios, making them durable and resistant to corrosion. In terms of performance, aluminum sheets are versatile, used in various industries such as construction, automotive, and aerospace. They conduct heat and electricity well, which is beneficial for applications requiring thermal or electrical conductivity. However, they may be more expensive than some plastics or cheaper metals like steel on a per-unit basis, but their lower weight and durability often offset this cost over time.</p>

- Q: Are aluminum sheets suitable for food storage containers?

- Yes, aluminum sheets are suitable for food storage containers. Aluminum is a safe and durable material that is resistant to corrosion, making it ideal for storing and preserving food. It also has excellent heat conduction properties, allowing for even cooking and reheating.

- Q: Can aluminum sheets be used for outdoor furniture?

- Yes, aluminum sheets can be used for outdoor furniture. Aluminum is a popular choice for outdoor furniture due to its durability, lightweight nature, and resistance to rust and corrosion. It is commonly used to make outdoor tables, chairs, and other furniture pieces.

- Q: Over the years, the thermite reaction has been used for welding railroad rails, in incendiary bombs, and to ignite solid-fuel rocket motors. The reaction is given below.Fe2O3(s) + 2 Al(s) 2 Fe(l) + Al2O3(s)What masses of iron(III) oxide and aluminum must be used to produce 10.0 g iron?a) iron (III) oxideb)aluminiumc)What is the maximum mass of aluminum oxide that could be produced?

- i'm uncertain regardless of the incontrovertible fact that it must be relaxing, are you making thermite? i might guess which you would be able to artwork this out from the atomic weights of each, and taking the valencies under consideration - 2 aluminium atoms for 3 oxygen atoms. 2 iron atoms for 2 oxygen (a million:a million).

- Q: How do aluminum sheets perform in terms of fatigue resistance?

- Aluminum sheets possess outstanding fatigue resistance, showcasing their ability to endure repeated stress and strain cycles without significant degradation in their mechanical properties. The exceptional fatigue resistance of aluminum sheets primarily stems from their microstructure, characterized by small and uniformly dispersed grains. This microstructure aids in the even distribution of applied stress throughout the material, effectively preventing crack formation and propagation. Moreover, fatigue resistance in aluminum sheets can be further enhanced through various processing techniques, such as heat treatment, alloying, and surface treatments. These techniques serve to refine the microstructure, enhance strength, and elevate the overall fatigue performance of the material. Furthermore, aluminum's relatively low density compared to other metals contributes to its superior fatigue resistance. This lower density enables improved energy absorption during cyclic loading, thereby reducing the likelihood of crack initiation and propagation. It is worth noting, however, that the fatigue resistance of aluminum sheets can vary depending on the specific alloy, temper, and thickness. Different aluminum alloys possess distinct mechanical properties and fatigue limits, necessitating the selection of the appropriate alloy and temper based on specific application requirements. In conclusion, aluminum sheets are highly esteemed for their remarkable fatigue resistance, making them a favored choice in industries that demand materials capable of enduring cyclic loading and extended service life.

- Q: Are 101 aluminum sheets available in different finishes (e.g., brushed, polished)?

- Yes, 101 aluminum sheets are available in different finishes such as brushed and polished. These finishes are achieved through various processes that result in different textures and appearances on the surface of the aluminum sheets. Brushed finishes are created by brushing the surface of the sheet with an abrasive material, which creates a pattern of fine lines. This finish is commonly used to create a matte appearance. On the other hand, polished finishes are achieved by polishing the surface of the sheet to a high shine. This finish is often used to create a reflective and smooth surface. So, depending on the desired aesthetic or functional requirements, one can choose between brushed or polished finishes for 101 aluminum sheets.

Send your message to us

5052 Aluminum Sheets for Sale - Direct Casting Aluminium Coils for Secondary Rolling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords