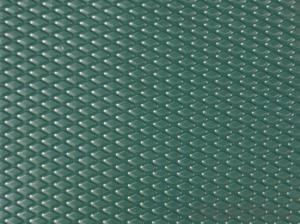

5mm Cost Price Alumet Baked Enamel Embossed Aluminum Alloy Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Company&Products Introducting

Established | 2012 years |

Product Type | Aluminium plate, Aluminium sheet, Aluminium coil, Aluminium strip.etc |

Product Martial | 1xxx series,3xxx series,5xxx series, 6xxx series,8xxx series |

Hardness state | HO,H14, H18, H24.etc |

Product Size | Thickness:0.1mm-10mm, 100mm<width<2000mm, Length :2000mm - 8000mm Also accept customized |

Surface Treatment | Mill finished |

Processed | Aluminium 5 bar, embossed plate, aluminium per-printed coil, aluminium tile,etc |

Min order quantity | 5 tons |

Short lead time | 15-20 days |

Application | Architectural/Decoration,Household,Transformer,Appliance,Transportation,Electrommunication,Food, etc |

Month Capacity | 5000 tons |

Accepted Payment Type | T/T,L/C |

Port of Loading | Shanghai |

Packing | Export wooden pallets. Customer's requests. |

Oversea Market | South America, Southeast Asia, Africa, Oceania, Mid East |

Ratio of Domestic/Export | 70%,30% |

Our advantage | Manufacture near from Shanghai reasonable price, various product, ensure quality |

Specifications:

1.Aluminum Sheet and Plate & Panel.

2.without oxidation and scratch.

3.Thickness:0.1mm-10mm

4.long-term of cooperation

5.the quality of the malitary level

- Q: Can aluminum sheets be used as heat shields?

- Yes, aluminum sheets can be used as heat shields. Aluminum has high thermal conductivity, which means it can effectively absorb and distribute heat, making it an excellent material for heat protection. It is commonly used in various applications such as automotive, aerospace, and industrial settings to shield sensitive components from high temperatures.

- Q: Can aluminum sheets be utilized as a material for constructing caravan roofs?

- <p>Yes, aluminum sheets can be used for caravan roofs. They are lightweight, durable, and resistant to corrosion, making them an ideal material for this purpose. Aluminum sheets are easy to install and maintain, and they can also reflect heat, helping to keep the interior of the caravan cooler. However, it's important to ensure that the aluminum sheets are of good quality and properly sealed to prevent water ingress and to maintain structural integrity over time.</p>

- Q: Is it possible to use aluminum sheets in environments with high temperatures?

- <p>Yes, aluminum sheets can be used in high-temperature environments, but with certain considerations. Aluminum has a high melting point of around 660掳C (1220掳F), which allows it to withstand high temperatures. However, its mechanical properties can degrade over time when exposed to sustained high temperatures, especially above 200掳C (392掳F). For applications requiring long-term exposure to high temperatures, special heat-resistant aluminum alloys or coatings may be necessary to maintain structural integrity and performance. It's also important to consider the specific conditions and the maximum temperature the aluminum will be exposed to when determining its suitability for a high-temperature application.</p>

- Q: Are aluminum sheets resistant to rust?

- Yes, aluminum sheets are highly resistant to rust due to their natural oxide coating that forms a protective barrier against corrosion.

- Q: Can aluminum sheets be used for cryogenic applications?

- Yes, aluminum sheets can be used for cryogenic applications. Aluminum has excellent thermal conductivity and can withstand low temperatures, making it suitable for cryogenic environments. Additionally, aluminum's lightweight and corrosion-resistant properties make it a popular choice in various cryogenic applications such as aerospace, scientific research, and cryogenic storage systems.

- Q: This question asks for a guide on the correct procedure to install aluminum sheets, likely for construction or renovation purposes.

- <p>To install aluminum sheets properly, follow these steps: 1. Prepare the surface by cleaning and leveling it. 2. Measure and cut the aluminum sheets to the required size using a metal saw or tin snips. 3. Apply a bead of construction adhesive along the edges of the surface where the sheets will be placed. 4. Position the aluminum sheet, ensuring it's aligned correctly. 5. Secure the sheet with screws or nails, using a washer to prevent tearing. 6. Seal the seams and edges with a weatherproof sealant to prevent water ingress. 7. Inspect the installation for any gaps or unevenness and make adjustments as needed. Always follow the manufacturer's guidelines and safety precautions while working with aluminum sheets.</p>

- Q: What is the flexural modulus of aluminum sheets?

- The measure of the stiffness or rigidity of aluminum sheets when subjected to bending or flexural stress is referred to as the flexural modulus. This mechanical property quantifies the aluminum sheet's resistance to deformation under applied force. Typically ranging between 69 GPa to 79 GPa, the flexural modulus of aluminum sheets depends on the specific alloy and temper. However, it is crucial to note that factors such as thickness, heat treatment, and manufacturing processes can cause slight variations in the flexural modulus. Aluminum is widely recognized for its exceptional strength-to-weight ratio, making it a favored choice for applications that require lightweight and durable materials. Due to its relatively high flexural modulus, aluminum sheets can maintain their shape and resist bending or flexing, making them suitable for uses in aircraft structures, automotive components, and building construction. It is important to highlight that the flexural modulus of aluminum can be improved through alloying elements or heat treatment processes. For instance, certain aluminum alloys like 7075 or 2024 may exhibit higher flexural modulus values due to their enhanced strength and stiffness properties. To summarize, the flexural modulus of aluminum sheets is a crucial mechanical property that determines their ability to withstand bending or flexural stress. This property provides valuable insights into the material's rigidity and assists engineers and designers in selecting the appropriate aluminum alloy and thickness for various applications.

- Q: Are aluminum sheets suitable for chemical processing?

- Aluminum sheets, indeed, prove to be fitting for chemical processing. Renowned for its superb resistance to corrosion, aluminum has gained popularity as a preferred option for tasks involving exposure to diverse chemicals. It develops a shielding oxide layer that halts further corrosion, even in demanding surroundings. Additionally, aluminum's lightweight characteristic facilitates its handling and transportation within the chemical processing sectors. Furthermore, aluminum excels as a heat conductor, enabling efficient temperature regulation during chemical reactions. All in all, when considering their corrosion resistance, lightweight composition, and commendable thermal conductivity, aluminum sheets emerge as a prudent selection for chemical processing endeavors.

- Q: iron-based alloys over aluminum in structural members of bridges and buildings?

- Aluminum generally has a better strength-to-weight-ratio. Steel alloys are still used in some of the parts of a typical aircraft, where tensile strength and toughness are the major considerations, over weight. The landing gear, bolts and pins, hinges, bearings, for example. Steel is used for bridges and buildings, because it's a lot *cheaper* than aluminum, and saving weight isn't nearly as critical as it is in aircraft. Steel is stiffer than aluminum, and It's easier and cheaper to make reliable welds in steel as well. Welding aluminum tends to be time consuming and expensive.

- Q: What is the fatigue strength of aluminum sheets?

- The fatigue strength of aluminum sheets depends on various factors such as the alloy, thickness, and manufacturing process. Generally, aluminum alloys have good fatigue strength compared to other materials. However, the exact fatigue strength can vary significantly and must be determined through specific testing and analysis for each particular aluminum sheet.

Send your message to us

5mm Cost Price Alumet Baked Enamel Embossed Aluminum Alloy Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords