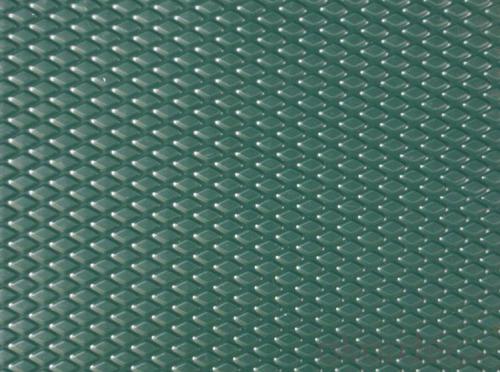

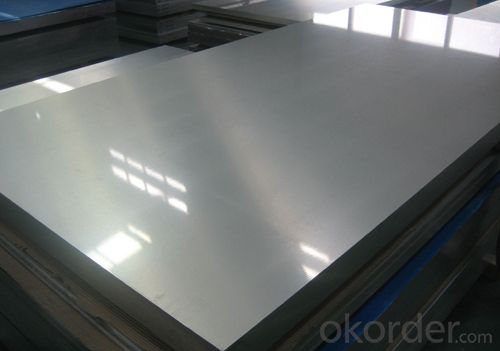

3mm Thickness Cost Price Embossed Thick Aluminum Foil Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of 3mm Thickness Cost Price Embossed Aluminum Sheet

Alloy | Temper | Specification(mm) | ||||

Thickness | Width | Length | Embossing Depth | Surface Treatment | ||

1050, 1060, 1100, 1070, 3003, 3105, etc. | O, H12, H14, H16, H18, H22, H24, H26, H32, etc. | 0.25~2.0 | ≤1250 | As per customer’s | 0.08~0.25 | Mill Finish, Bright Finish, Anodized, Color Coated |

Tolerance | ||||||

Thickness (base materials) | Thickness | Embossing Depth | Width | Length | Diagonal | |

0.25~0.5 | 0~0.05 | +/- 0.01 | +/-0.5 | +/- 1.0 | +/- 1.5 | |

> 0.5~2.0 | 0~0.10 | +/- 0.02 | +/-1.0 | +/- 1.5 | +/- 2 | |

We can produce as per customers’ special requirements. | ||||||

Chemical composition of 3mm Thickness Cost Price Embossed Aluminum Sheet

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Other | Min Al/ % | ||

Single | Total | ||||||||||||

3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | - | - | 0.10 | - | - | 0.05 | 0.15 | Remain |

3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | 0.15 | - | 0.25 | - | - | 0.05 | 0.15 | Remain |

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: What is the reflectivity of 101 aluminum sheets?

- The reflectivity of 101 aluminum sheets can vary depending on a few factors such as the surface finish, thickness, and any additional coatings or treatments applied to the sheets. Generally, aluminum has a high reflectivity, especially in the visible light spectrum. It can reflect around 80% to 90% of visible light, making it a popular material for reflective surfaces, mirrors, and various lighting applications. However, it is essential to note that the exact reflectivity of 101 aluminum sheets may differ based on specific manufacturing processes or variations in the material properties.

- Q: Are 101 aluminum sheets suitable for chemical processing equipment?

- 101 aluminum sheets are not suitable for chemical processing equipment. While aluminum is a versatile and widely used material, it is not recommended for applications involving strong acids or bases. Aluminum is susceptible to corrosion when exposed to certain chemicals, and this can compromise the integrity of the equipment and potentially lead to leaks or other safety hazards. For chemical processing equipment, it is advisable to choose materials that are specifically designed and manufactured to withstand the corrosive effects of the chemicals being used.

- Q: Can aluminum sheets be used for chemical storage containers?

- Yes, aluminum sheets can be used for chemical storage containers. Aluminum is known for its excellent corrosion resistance, which makes it suitable for storing a wide range of chemicals. It is also lightweight, durable, and non-reactive with most substances, making it a popular choice for chemical storage applications. Additionally, aluminum is easily formed and fabricated into various shapes and sizes, allowing for customized container designs. However, it is important to consider the specific chemical being stored and consult with experts to ensure compatibility and safety.

- Q: This question asks about the various applications of aluminum sheets within the construction industry.

- <p>Aluminum sheets are widely used in construction for their durability, lightweight, and resistance to corrosion. They are commonly used for roofing and cladding due to their ability to withstand harsh weather conditions. Aluminum sheets are also used in the manufacturing of window frames and doors because of their strength and thermal insulation properties. Additionally, they are utilized in the construction of scaffolding and temporary structures due to their ease of assembly and disassembly. In interior design, aluminum sheets can be used for decorative purposes, such as wall panels and ceilings. Their recyclability also makes them an environmentally friendly choice for construction projects.</p>

- Q: Can the aluminum sheets be used for manufacturing electrical connectors?

- Indeed, electrical connectors can be manufactured using aluminum sheets. The lightweight and exceptional conductivity of aluminum render it ideal for the efficient transmission of electricity. Its outstanding conductivity and ability to resist corrosion make it a frequently employed material in diverse electrical applications, particularly connectors. Furthermore, the malleability and ease with which aluminum can be molded into diverse connector designs make it an adaptable material for the production of electrical connectors.

- Q: Can aluminum sheet be painted or coated after fabrication?

- Yes, aluminum sheet can be painted or coated after fabrication. The surface of the aluminum sheet can be prepared by cleaning and etching to ensure proper adhesion of the paint or coating.

- Q: Are aluminum sheets suitable for roofing?

- Yes, aluminum sheets are suitable for roofing. They are lightweight, durable, and resistant to corrosion, making them an excellent choice for roofing materials. Additionally, aluminum sheets have good thermal properties, reflecting sunlight and helping to keep the building cool.

- Q: What's the difference between laser cutting aluminum plate and stainless steel plate?

- Aluminum plate reflectivity high, viscous strong, general 3mm above will hang slag, but very easy to peel off, stainless steel cutting ability and thickness and equipment power relationship more.

- Q: How do aluminum sheets perform in terms of creep resistance?

- Aluminum sheets generally exhibit good creep resistance, especially when compared to other metals. Aluminum has a low melting point and high thermal conductivity, which helps in reducing creep deformation. It also has a fine-grained microstructure that enhances its resistance to creep. However, it is important to note that the creep resistance of aluminum sheets can be affected by factors such as temperature, load, and alloy composition.

- Q: Can aluminum sheets be used for reflectors?

- Indeed, reflectors can utilize aluminum sheets. Renowned for its remarkable reflectivity properties, aluminum emerges as an optimal substance for a multitude of reflector applications. Its exceptional reflectivity empowers it to deftly redirect and bounce light, rendering it fitting for deployment in diverse devices such as illumination apparatus, solar panels, telescopes, and other instruments that necessitate precise and effective light reflection. Moreover, aluminum's lightweight nature, durability, and resistance to corrosion render it a pragmatic selection for reflectors that must endure formidable environmental circumstances.

Send your message to us

3mm Thickness Cost Price Embossed Thick Aluminum Foil Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords