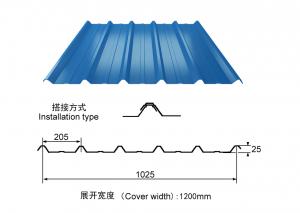

1-10mm Cost Price Embossed Aluminum Corrugated Metal Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Grade:

1000 Series,3000 Series,4000 Series,5000 Series,6000 Series,7000 Series,2000 Series

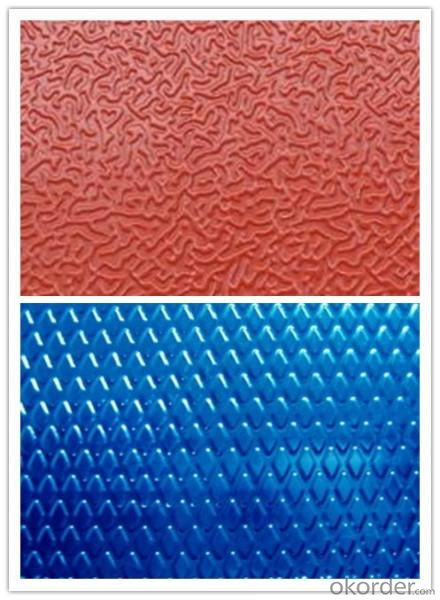

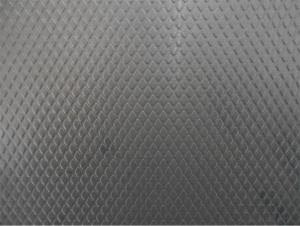

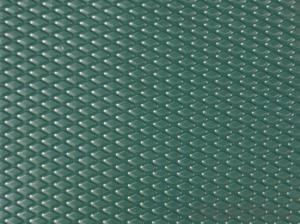

Surface Treatment:

Coated,Embossed,Anodized,Polished,Mill Finish,Color Coated,Oxidized,Enameled Wire,Brushed,Printed,Composited,Holographic Impression,Sand Blasted,Powder Coating

Shape:

Angle,Square,T-Profile,Round,Flat,Rectangular,Oval,Hexagonal

Temper:

T3-T8,O-H112,T351-T651,T351-T851,Soft,Half Hard,Hard

Application:

Liner & Wad,Decorations,Door & Window,Heat Sink,Transportation Tools,Glass Wall,Food,Kitchen Use,Pharmaceutical,Seal & Closure,Insulation Material,Label & Tag

Parameters:

| Division | Description | Application | Feature |

| 1000 SERIES | 1050 1060 1090 1100 representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. | Utensil, decoration, Reflecting plate, printing plate, heatproof plate,cookware | Easy to process and weld,resistant to rust,high,conductibility of electricity and heat,low strength |

| 3000 SERIES | 3xxx series aluminum represents 3003 3004,3005. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment | Utensil(F/P, inside of rice cooker), aluminum can,material for interior and exterior of building,chemical equipment,Cellular Phone | 20% higher strength than the 1100 series, easily welded and brazed, good antirust,ability Non-heat treatable |

| 5000 SERIES | 5xxx series representatives 5052 5005 5083,5754. The 5000 series aluminum alloy aluminum belong to the more commonly used series, the main elements for magnesium, with magnesium in the amount between 3-5%. And can be called aluminum magnesium alloy. Key features for low density, high tensile strength, elongation rate is high. In the same area under the weight of the magnesium alloy aluminum less than other series. | Ship board heatproof apparatus, material for interior and exterior of building, Parts of Electronic tools.Automobile Components | Excellent corrosion resistance andweld ability together with Easy to process and weld and superior hardness &heatproof Can be anodized for increased corrosion resistance |

| 6000 SERIES | 6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications. | IT equipment & facility, Mould material, motor material, automatic line, machine & plant etc | Easy to process , good corrosion resistance, high toughness and processed without distortion after heat-treatable, superior surface treatment |

| 7000 SERIES | 7000 aluminum alloy is another common alloy, wide variety. It contains zinc and magnesium. The best strength in the common aluminum alloy is 7075 alloy, but it can't be welded, and its corrosion resistance is rather poor, many manufacturing parts with CNC cutting is 7075 alloy. | The aerospace industry & High strength accessories | 7000 series is high tensile to process with special alloy |

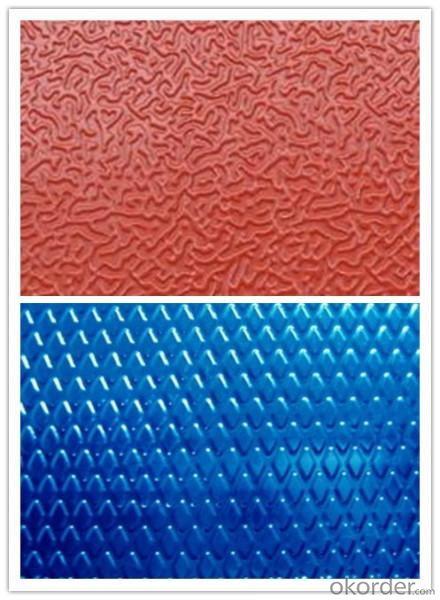

Product picture

- Q: Are aluminum sheets suitable for electrical connectors?

- Yes, aluminum sheets are suitable for electrical connectors. Aluminum is a highly conductive metal, which makes it an excellent choice for transferring electric current. It has a low electrical resistance, allowing for efficient transmission of electricity. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective, making it a popular material for electrical connectors in various industries such as automotive, aerospace, and electronics. However, it is important to note that aluminum connectors may require additional measures to prevent galvanic corrosion when used with dissimilar metals.

- Q: Can aluminum plates be welded with stainless steel or iron nuts?

- If the thickness of the sheet is not enough, the effective thread stroke can be mounted with K nuts. Rivet nuts are required if accuracy is required.If it is a thick aluminum sheet, it can be directly drilled and tapped; also, the steel screw sleeve can be added.

- Q: How do you prevent surface marring of aluminum sheets during handling?

- To prevent surface marring of aluminum sheets during handling, there are several steps you can take: 1. Use clean gloves or finger cots: When handling aluminum sheets, it is important to avoid direct contact with bare hands as they may contain oils, dirt, or other contaminants that can leave marks on the surface. Wearing clean gloves or finger cots can provide a barrier and prevent any transfer of substances onto the sheets. 2. Use protective packaging: Prior to handling, consider using protective packaging such as foam or plastic sheets to cover the surface of the aluminum sheets. This will provide an additional layer of protection against scratches or abrasions during transportation or storage. 3. Implement proper storage and handling techniques: Store aluminum sheets in a clean and dry environment, away from any abrasive materials or surfaces. When moving or handling the sheets, ensure that they are lifted or supported evenly to avoid any bending or distortion that may lead to surface marring. Using appropriate lifting equipment, such as suction cups or clamps, can help distribute the weight evenly and minimize the risk of damage. 4. Clean the surface regularly: Regularly clean the aluminum sheets using a mild detergent or aluminum-specific cleaning solution. This will help remove any dirt, grime, or other substances that could potentially cause surface marring. Be sure to use soft, non-abrasive cleaning tools such as microfiber cloths or sponges to avoid scratching the surface. 5. Implement quality control measures: Establishing quality control measures during the handling process can help identify any potential sources of surface marring. Regular inspections should be conducted to check for any signs of damage or defects. Implementing proper training for employees involved in the handling process can also help minimize the risk of surface marring. By following these preventive measures, you can significantly reduce the chances of surface marring on aluminum sheets during handling, ensuring their pristine condition and quality.

- Q: What are the rules or laws concerning the application of flame-retardant coatings on aluminum sheets?

- <p>Yes, there are regulations regarding the use of flame-retardant coatings on aluminum sheets. These regulations vary by country and application, but they generally aim to ensure safety and compliance with fire safety standards. In the United States, for example, the National Fire Protection Association (NFPA) provides guidelines, and building codes like the International Building Code (IBC) may specify requirements for flame retardancy. The European Union has its own set of standards, such as EN 13501, which classifies the reaction to fire performance of construction products. Compliance with these regulations is crucial to ensure that the aluminum sheets and their coatings meet the necessary safety standards and to avoid legal penalties.</p>

- Q: What does exterior wall imitate aluminium paint have? Imitate aluminium plate paint is fluorocarbon paint?

- If not missing the cost or use aluminum plate, because the fluorine content of fluorocarbon metal paint paint factory production lot are not enough, so the warranty 10-15 years is just a pretext, and the construction of the technical requirements for workers is relatively high.

- Q: What are the standards and certifications available for aluminum sheets?

- Aluminum sheets can be evaluated for quality and compliance with industry requirements through various standards and certifications. Some well-known ones include: 1. ASTM International Standards: Developed by the American Society for Testing and Materials (ASTM), these standards focus on aspects like chemical composition, mechanical properties, and dimensional tolerances. They promote consistent quality across different aluminum sheet products. 2. ISO 9001: This globally recognized certification establishes guidelines for quality management systems. Aluminum sheet manufacturers with ISO 9001 certification demonstrate their commitment to meeting customer requirements, continuous improvement, and strict quality control processes. 3. ASME Standards: The American Society of Mechanical Engineers (ASME) has specific standards for aluminum sheet materials used in pressure vessels, piping, and other applications. These standards ensure the safety and reliability of aluminum sheets in critical applications. 4. MIL-Specifications: The United States Department of Defense (DoD) has developed military specifications (MIL-Specs) for materials, including aluminum sheets. These specifications define the requirements for military-grade aluminum sheets, ensuring their suitability for defense applications. 5. EN Standards: The European Committee for Standardization (CEN) has established a series of European Norm (EN) standards for aluminum and aluminum alloys. These standards cover chemical composition, mechanical properties, and surface finishes, ensuring compatibility and consistency in the European market. 6. RoHS Compliance: Compliance with the Restriction of Hazardous Substances (RoHS) is crucial for aluminum sheets used in electrical and electronic equipment. This certification guarantees that the aluminum sheets are free from hazardous substances, ensuring environmental safety. Manufacturers and suppliers of aluminum sheets must adhere to these standards and certifications to ensure their products are of the highest quality, safety, and suitability for specific applications.

- Q: What is the maximum width available for aluminum sheets?

- The maximum width available for aluminum sheets can vary depending on the manufacturer and specific requirements. However, in general, aluminum sheets are commonly available in widths up to 72 inches or 1.83 meters. It is important to note that some manufacturers may offer even wider options for specialized applications. Additionally, custom sizes can also be obtained through specific orders, allowing for greater flexibility in width choices.

- Q: Can the aluminum sheets be used in the construction industry?

- Yes, aluminum sheets can definitely be used in the construction industry. Aluminum is a versatile and lightweight material that offers several advantages for construction applications. It is corrosion-resistant, which makes it ideal for outdoor structures and buildings. Aluminum sheets are commonly used for roofing, siding, window frames, doors, and other architectural elements. Additionally, aluminum's high strength-to-weight ratio allows for the construction of durable and efficient structures. Its malleability also makes it easy to fabricate and shape into various forms, allowing for creative and innovative designs in construction projects. Overall, aluminum sheets are a popular choice in the construction industry due to their durability, versatility, and aesthetic appeal.

- Q: Are the aluminum sheets suitable for outdoor applications?

- Yes, aluminum sheets are suitable for outdoor applications. Aluminum is highly resistant to corrosion and weathering, making it an ideal choice for outdoor use. Additionally, aluminum sheets are lightweight, durable, and have excellent thermal and electrical conductivity, further enhancing their suitability for various outdoor applications.

- Q: I've heard certain eyeliners contain lead and that it's a harmful (cancerous) ingredient. I use Urban Decay's 24/7 eyeliner and on the box it says it contains aluminum powder. Is that another word for lead? If not, is aluminum powder harmful too? Thanks!

- Nope - not lead. Aluminum is one of the most common substances in the earths crust. Shouldn't hurt you. And actually fancy ladies covered their faces with white lead for a LONG time (Queen Elizabeth I white face was from white lead) - and these people didn't die even though they had quite a poisonous stuff on their skin.

Send your message to us

1-10mm Cost Price Embossed Aluminum Corrugated Metal Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords