4 Foot By 8 Foot Brushed Aluminum Sheets for Ceiling Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Brushed Aluminum Sheet for Ceiling Decoration

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Brushed Aluminum Sheet for Ceiling Decoration

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

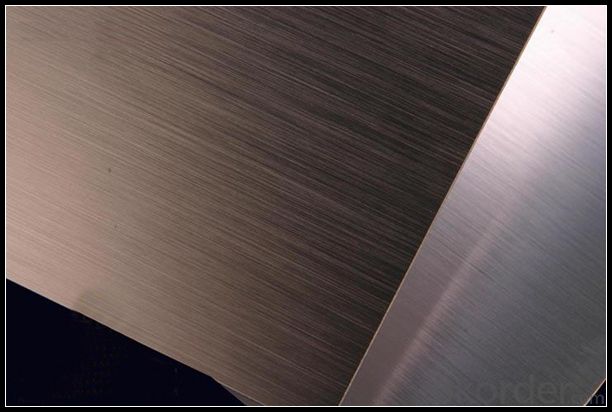

3. Brushed Aluminum Sheet for Ceiling Decoration Images

4.Specification of Brushed Aluminum Sheet for Ceiling Decoration

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: How are aluminum sheets tested for quality and compliance with industry standards?

- Quality and compliance with industry standards for aluminum sheets are ensured through a comprehensive range of tests and inspections. These tests guarantee that the desired specifications and performance criteria are met by the sheets. Visual inspection is one of the commonly utilized tests, where the sheets are thoroughly examined for any surface defects like scratches, dents, or cracks. This examination is crucial to ensure a flawless and smooth appearance. Furthermore, dimensional checks are carried out to verify the thickness, width, and length of the sheets. Precise measurements are essential to meet the specific requirements of the intended application. Various tests are conducted to evaluate the mechanical properties. Tensile strength tests assess the maximum load the aluminum sheet can bear before breaking. This aids in determining the structural integrity of the sheet and its ability to withstand external forces. Similarly, hardness tests measure the sheet's resistance to indentation or penetration, providing insights into its durability and resistance to wear. Chemical composition analysis is also undertaken to ensure that the aluminum sheets contain the necessary alloying elements within the specified limits. This analysis helps confirm that the material composition aligns with industry standards, as different alloy compositions can affect the mechanical properties of the sheets and their suitability for various applications. Corrosion resistance tests assess the sheet's capacity to withstand environmental factors like moisture, chemicals, and temperature variations, thereby evaluating its surface integrity. This evaluation is particularly important for applications where aluminum sheets are exposed to corrosive substances or harsh environments. In addition to these tests, non-destructive testing techniques such as ultrasonic testing or eddy current testing may be employed on aluminum sheets. These methods help identify internal defects or irregularities that may not be visible through visual inspection alone. Overall, a combination of visual inspections, dimensional checks, mechanical tests, chemical composition analysis, and surface integrity evaluations are utilized to ensure that aluminum sheets meet the quality standards and compliance requirements set by the industry. These rigorous testing procedures guarantee that the sheets are suitable for their intended purpose and fulfill the expectations of customers.

- Q: Are the aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are suitable for aerospace applications due to their lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance, making them ideal for aircraft structures and components. Moreover, aluminum's ability to be easily machined, formed, and welded further enhances its suitability for aerospace use.

- Q: What is the width and length of the aluminum sheets?

- The width and length of the aluminum sheets can vary depending on the specific product or manufacturer. It would be best to consult the product specifications or contact the manufacturer for accurate measurements.

- Q: Can aluminum sheets be embossed or engraved?

- Aluminum sheets have the capability to be embossed or engraved. The act of embossing entails the formation of a raised design or pattern on the aluminum sheet's surface, whereas engraving involves the cutting or etching of a design into the surface. These techniques are applicable for incorporating decorative or functional elements into aluminum sheets. In numerous industries, such as automotive, aerospace, signage, and architectural applications, embossed or engraved aluminum sheets are commonly employed. The process of embossing or engraving aluminum sheets typically necessitates the utilization of specialized machinery or tools to achieve the desired design.

- Q: How is an aluminum sheet manufactured?

- An aluminum sheet is manufactured through a process called rolling, where a large ingot of aluminum is heated and passed through a series of rollers to reduce its thickness and increase its length. This continuous rolling process is repeated until the desired thickness is achieved, and the aluminum sheet is then cut into various sizes and shapes.

- Q: on an hot day, which will stay cooler longer...aluminum, or copper? why?thanks!

- aluminum will stay cooler longer conducts only almost half as much heat at a given temperature than copper yet it also it loses heat quickly. copper is a great conductor of heat so it will heat up faster and also it holds that energy much longer.

- Q: What is the use?

- The three and 3000 series aluminum on behalf of 300330033A21. Also known as China's 3000 series aluminum antirust aluminum production process is more outstanding.3000 series aluminum is made of manganese as main components. The contents of 1.0-1.5 in between. Is a series of anti rust function better. Routine application in air conditioning, ice box, car etc. in the moist environment, price more than 1000 written columns, is a commonly used alloy series.The four and 4000 series aluminum aluminum on behalf of 4A014000 series belongs to the high silicon content series. Usually silicon content between 4.5-6.0%. Belongs to the building material, mechanical parts, forging materials, welding materials; low melting point, good corrosion resistance of the product description: has the characteristics of heat resistance, wear resistanceThe five and 5000 Series 5052.5005.5083.5A05 series.5000 series aluminum plate belongs to the representative of the more commonly used aluminium alloy series, the main elements of magnesium, magnesium content in 3-5%. Also called aluminum magnesium alloy. The main characteristics of low density, high tensile strength, elongation rate is high. In the same area under the weight of the aluminium magnesium alloy is lower than that of other series. It is commonly used in aviation, such as aircraft fuel tank. The application in the conventional industries are more widely. The processing technology for slab continuous casting and rolling, which belongs to the aluminum plate series so can do deep processing. Oxidation belongs to one of the more mature aluminum series in China 5000 series aluminum plate.

- Q: Are aluminum sheets suitable for pharmaceutical applications?

- Aluminum sheets are well-suited for pharmaceutical use, as they possess a range of advantageous properties. Firstly, their lightweight nature and exceptional resistance to corrosion make them an ideal choice for packaging pharmaceutical products. By shielding the contents from external factors like moisture, light, and oxygen, which could potentially compromise the medication's quality, aluminum sheets offer excellent protection. Additionally, aluminum sheets are highly malleable and can easily be molded into different shapes and sizes, allowing for customized packaging designs. Moreover, their availability in various thicknesses provides options for different types of pharmaceutical products, including tablets, capsules, and liquid medications. Furthermore, aluminum sheets boast a remarkable barrier property that effectively prevents the transfer of odors, flavors, and contaminants. This barrier ensures the integrity and safety of the medication throughout its entire shelf life. Furthermore, aluminum is a non-toxic material, guaranteeing that it does not react with drugs or alter their composition. This quality makes it an optimal choice for pharmaceutical applications, where maintaining the purity and stability of the medication is of utmost importance. In conclusion, aluminum sheets are highly suitable for pharmaceutical applications, thanks to their lightweight nature, corrosion resistance, barrier properties, and non-toxic composition. By efficiently safeguarding and preserving pharmaceutical products, they ensure the quality and safety of these crucial medications.

- Q: The furnace above is only hot enough to melt lead, but isn't hot enough to melt aluminum. I'm not looking for a blowtorch, or something too expensive or could melt gold, but just something that i can buy and is like the one above but isn't that expensive and can melt aluminum. Thanks!

- Aluminum melts below 1300F These gold and silver melters like the one in the link go to 2000F or more and should work for aluminum. I guess more small melters of metals want to melt gold and silver than aluminum.

- Q: Are aluminum sheets suitable for automotive heat shields?

- Yes, aluminum sheets are suitable for automotive heat shields. Aluminum is a lightweight and highly conductive material, making it an excellent choice for heat management in automotive applications. It has a high melting point and good thermal conductivity properties, allowing it to effectively absorb and dissipate heat generated by the vehicle's engine, exhaust system, or other heat sources. Additionally, aluminum sheets are easy to shape and form into various sizes and designs, making them versatile for different automotive heat shield applications. Overall, aluminum sheets provide a cost-effective and efficient solution for protecting sensitive components from heat damage in automotive systems.

Send your message to us

4 Foot By 8 Foot Brushed Aluminum Sheets for Ceiling Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords