300 Serises Stainless Steel Suppliers in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

300 Serises Stainless Steel Suppliers in China

Product Description

1 | Product Name | stainless steel suppliers |

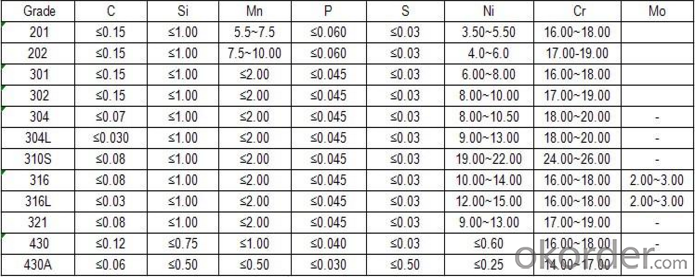

2 | Material | ASTM 301, ASTM304,ASTM304L, ASTM 316, ASTM316Ti,ASTM309S, ASTM310S, ASTM321, ASTM347H,ASTM A317,ASTMA317L, ASTM409,ASTM409L,ASTM410,ASTM420,ASTM430 ASTM 201,ASTM202, |

3 | Technique | Cold Rolled Stainless Steel plate Cold Drawn Stainless Steel plate Hot Rolled Stainless Steel plate |

4 | Standard | ASTM,AISI,ASME,JIS,SUS,DIN,EN,GB,BS |

5 | Thickness | 0.2-6.0mm for cold rolled 3.0-300mm for hot rolled |

Width | 600-3000mm | |

Length | Any, as your requirement | |

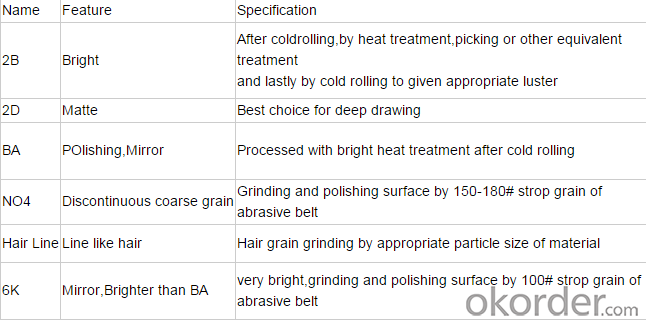

6 | Surface Treatment | No.1, NO.4 ,2B, BA, Hair Line,8K,Brush,Embossed and Mirror Finish or as your demand |

7 | Packing | Standard export packing-For stainless steel sheet 1.surface polish 2. bundle package 3. wooden case , wooden pallet package 4:container or bulk 5. special according to customer request |

8 | Delivery | Normally according to the order quantity or upon negotiation |

9 | Price Item | FOB,CFR,CIF Or as negotiated |

10

| Application | Stainless Steel plate are widely used in below fields: 1: Construction feild,shipping building industry 2: Petroleum and Chemical Industries 3: Food and Machenical Industries 4: Boiler Heat Exchange |

Surface of stainless steel suppliers

Chemical component of stainless steel supplier

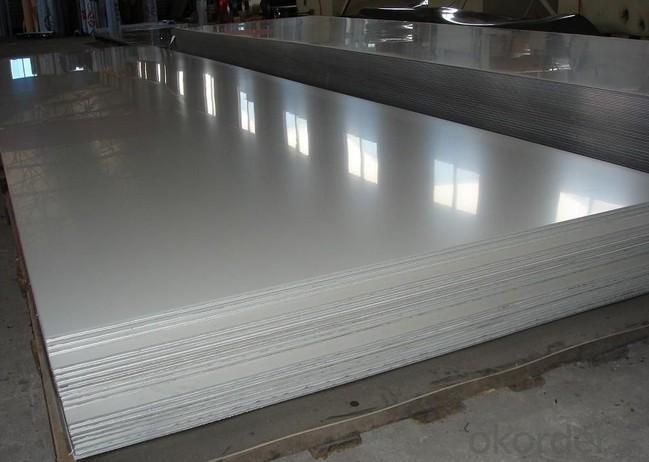

Product show

Packaging & Shipping

Our main products are stainless steel inox sheet/plate,coil/roll,strip,bar,angle,pipe and tube .

Grades are 201,202,304,304L,316,316L,310S,309S,301,321,904L,410,420,430,409.

Surface--we have 2B,BA,No.4/HL/Hairline/brushed/satin,8K/No.8/mirror,SB,gold,etch,No.1,polish,etc.

Thickness--0.2-6mm for cold rolled; 3-150mm for hot rolled.

Standard size--1000×2000mm,1219×2438mm=4ft×8ft=1220×2440mm,

1250×2500mm,1500×3000/6000mm,1524×6096mm,2000×6000mm.

Certificate--ISO,BV,SGS,TUV,IQI or other third inspections.

Package--wooden pallets without fimugated,iron pallets,water proof papers,

interleaved paper,pvc film,20'GP or 40'GP container.

Delivery time-- 5-7 days for standard sizes,less than 100Tons,

other quantity is as the actual situations.

Advantage--Corrosion resistant ,Compressive strength,none magnetic,magnetic

Application--stainless steel sheet/plate

Stainless steels of various kinds are used in thousands of applications. The following gives a flavour of the full range:

1.Domestic cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

2.Transport exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles

3.Oil and Gas – platform accommodation, cable trays, subsea pipelines.

4.Medical Surgical instruments, surgical implants, MRI scanners.

5.Food and Drink – Catering equipment, brewing, distilling, food processing.

6.Water – Water and sewage treatment, water tubing, hot water tanks.

7.General – springs, fasteners (bolts, nuts and washers), wire.

8.Chemical/Pharmaceutical – pressure vessels, process piping.

9.Architectural/Civil Engineering – cladding, handrails, door and window fittings, street furniture, structural sections,reinforcement bar, lighting columns, lintels, masonry supports

FAQ

Small quantity, short time delivery

If we have stocks, the delivery time is less than 7 days,If the quantity is more than 500Tons,the delivery time is abou 30 days after confirming the order.

Choose the appropriate metals stainless steel for your needs.

We carefully balance quality, delivery time and price,procure various grades metals from all over the world.

Lower total cost

We taking your processing into account,offer you reduce a total cost by using our product.

We assure you:

Small MOQ + Cheap Price + Fantastic Quality + Fast Delivery

- Q: Can stainless steel sheets be used for hygienic environments?

- Stainless steel sheets are indeed suitable for hygienic environments. This is because stainless steel possesses certain inherent properties that render it highly resistant to corrosion, heat, and chemical damage, thus making it a popular choice for such environments. Its surface is smooth and non-porous, which facilitates easy cleaning and prevents the accumulation of bacteria, mold, or other contaminants. Furthermore, stainless steel is non-reactive and does not release any harmful substances, making it ideal for sensitive environments like food processing facilities, hospitals, pharmaceutical labs, and cleanrooms. Moreover, stainless steel is both durable and long-lasting, ensuring excellent hygiene and cleanliness for extended periods. All in all, stainless steel sheets are a dependable and hygienic option for various applications in environments that prioritize cleanliness and sanitation.

- Q: How do I prevent rusting on stainless steel sheets?

- To prevent rusting on stainless steel sheets, it is important to keep them clean and dry. Regularly clean the sheets with mild soap and water, and avoid using abrasive cleaners or scrubbing tools that can damage the protective layer. Additionally, ensure the sheets are completely dry after cleaning to prevent moisture accumulation. Applying a coat of mineral oil or a stainless steel cleaner can also help create a barrier against rust.

- Q: How do you prevent intergranular corrosion on stainless steel sheets?

- Intergranular corrosion, which causes structural damage and reduced strength, occurs along the grain boundaries of stainless steel. To prevent this corrosion on stainless steel sheets, several steps can be taken: 1. Material Selection: To prevent intergranular corrosion, it is crucial to select the appropriate grade of stainless steel. Grades like 304L or 316L, which have low carbon content, are less susceptible to this type of corrosion due to their reduced sensitivity to sensitization. 2. Heat Treatment: One can heat treat stainless steel sheets to eliminate carbide precipitation, a common cause of intergranular corrosion. This process, known as solution annealing or sensitization heat treatment, involves heating the material to a specific temperature range and rapidly cooling it. This treatment ensures the formation of a consistent and corrosion-resistant microstructure. 3. Passivation: Passivation is a chemical process that removes contaminants and forms a protective oxide layer on the surface of stainless steel sheets. This layer acts as a barrier against corrosion and prevents intergranular attack. Typically, nitric acid or citric acid solutions are used for passivation. 4. Welding Techniques: Proper welding techniques should be employed when welding stainless steel sheets to minimize the risk of intergranular corrosion. This includes using low heat input, preventing excessive heat build-up, and using filler materials with low carbon content to prevent sensitization. 5. Avoiding Contamination: It is essential to protect stainless steel sheets from contamination by other metals, particularly those with higher galvanic potentials. Contact with carbon steel, for instance, can lead to galvanic corrosion and promote intergranular attack. Therefore, it is important to store and fabricate stainless steel sheets separately from other metals. 6. Regular Cleaning and Maintenance: Regularly cleaning and maintaining stainless steel sheets is vital to prevent the accumulation of corrosive substances or contaminants on the surface. Non-abrasive cleaners and proper cleaning methods should be used to avoid scratching the stainless steel, as scratches can create sites for corrosion initiation. By implementing these preventive measures, one can significantly reduce intergranular corrosion, ensuring the durability and performance of stainless steel sheets.

- Q: What is the difference between stainless steel sheets and plates?

- Stainless steel sheets and plates are both types of flat metal materials that are widely used in various industries and applications. However, there are a few key differences between them. 1. Thickness: Stainless steel sheets are generally thinner than plates. Sheets typically have a thickness ranging from 0.4mm to 4mm, whereas plates are usually thicker, starting from 4mm and going up to several inches. 2. Size: Sheets are typically available in standard sizes of 4ft x 8ft or 5ft x 10ft, while plates are usually available in larger sizes and can be customized to specific dimensions. Plates are commonly used for heavy-duty applications that require greater strength and durability. 3. Weight: Due to their difference in thickness, plates are generally heavier than sheets. This makes plates more suitable for applications where weight-bearing capacity is critical, such as construction, shipbuilding, or industrial equipment. 4. Applications: Stainless steel sheets are commonly used for decorative purposes, architectural applications, and smaller-scale projects such as kitchen backsplashes or countertops. Plates, on the other hand, are preferred for structural components, machinery parts, and load-bearing applications like bridges, tanks, or pressure vessels. 5. Cost: Stainless steel plates are generally more expensive than sheets due to their larger size and higher thickness. Sheets, being thinner and smaller, are usually more cost-effective and easily accessible. In summary, the key differences between stainless steel sheets and plates are their thickness, size, weight, applications, and cost. It is important to consider these factors when choosing between the two materials for a specific project or application.

- Q: Are stainless steel sheets suitable for elevator control panels?

- Stainless steel sheets are indeed appropriate for elevator control panels. This resilient and impervious material is capable of enduring diverse environmental conditions, such as continuous usage, moisture, heat, and chemicals. Elevator control panels necessitate a substance that is effortless to cleanse, resistant to marks and deformations, and visually pleasing. Stainless steel fulfills all of these requirements, rendering it an optimal selection for elevator control panels. Moreover, stainless steel possesses a sleek and contemporary look, thereby augmenting the overall design of the elevator interior.

- Q: Are stainless steel sheets suitable for railway station platforms?

- Railway station platforms can benefit from the use of stainless steel sheets. This material is known for its durability, making it a suitable choice for platforms that experience heavy foot traffic and extreme weather conditions. Its resistance to corrosion is especially important in areas exposed to moisture, like platforms where rain, snow, or spilled liquids may occur. Furthermore, stainless steel sheets are easy to clean and maintain, ensuring a hygienic and safe environment for passengers. The sleek and modern appearance of stainless steel also adds to the overall aesthetic appeal of the railway station. In summary, stainless steel sheets possess the necessary strength, durability, and aesthetic qualities required for railway station platforms.

- Q: What is the difference between hot rolled and cold rolled stainless steel sheets?

- Hot rolled and cold rolled stainless steel sheets differ in their manufacturing process, resulting in distinctive characteristics and properties. Hot rolled stainless steel sheets are manufactured by passing the stainless steel through a series of rollers at a high temperature. This process results in a thicker and rougher surface compared to cold rolled sheets. Hot rolling allows for faster production and is generally more cost-effective. However, the rougher surface may require additional processing, such as grinding or polishing, to achieve the desired finish. On the other hand, cold rolled stainless steel sheets are manufactured by cooling the hot rolled sheets and then annealing them in a controlled environment. This process improves the surface finish, resulting in a smoother and more uniform appearance. Cold rolling also allows for tighter tolerances and greater strength, making it suitable for applications that require precise dimensions and superior mechanical properties. In terms of strength and hardness, cold rolled stainless steel sheets generally exhibit greater strength and hardness compared to hot rolled sheets. This is due to the strain hardening that occurs during the cold rolling process. Cold rolled sheets are also less susceptible to deformation and warping, making them ideal for applications where flatness is critical. In summary, the main differences between hot rolled and cold rolled stainless steel sheets lie in their manufacturing process, surface finish, dimensional tolerance, and mechanical properties. Hot rolled sheets are thicker and have a rougher surface, while cold rolled sheets are thinner, smoother, and exhibit greater strength and hardness. The choice between the two depends on the specific requirements of the application and the desired aesthetic and functional characteristics.

- Q: Can stainless steel sheets be used for railway station facades?

- Yes, stainless steel sheets can be used for railway station facades. Stainless steel is a durable and corrosion-resistant material that can withstand harsh weather conditions, making it suitable for exterior applications. It also has an attractive and modern appearance, making it a popular choice for architectural design. Additionally, stainless steel sheets are easy to clean and maintain, which is important for high-traffic areas like railway stations. Overall, stainless steel sheets are a suitable and practical option for railway station facades.

- Q: Are stainless steel sheets suitable for marine environments?

- Yes, stainless steel sheets are suitable for marine environments. Stainless steel is highly resistant to corrosion and rust due to the presence of chromium in its composition. This makes it an ideal material for use in marine environments where constant exposure to saltwater and moisture can cause other metals to corrode quickly. Stainless steel sheets also have good mechanical properties, high strength, and excellent durability, which further make them suitable for marine applications. Additionally, stainless steel is easy to clean and maintain, ensuring its longevity and performance in harsh marine conditions.

- Q: Can stainless steel sheets be used for solar panels?

- Solar panels can indeed utilize stainless steel sheets. This material possesses a strong and reliable nature that withstands corrosion, thus making it suitable for long-term and outdoor usage. It offers exceptional defense against environmental elements like moisture and UV radiation, which are commonly encountered in solar panel installations. Furthermore, stainless steel showcases commendable thermal conductivity, promoting efficient dissipation of heat from the solar cells. This characteristic aids in maximizing the energy conversion efficiency of the panels. Additionally, stainless steel sheets present a sleek and polished surface, enhancing the visual appeal of the solar panels. All in all, stainless steel sheets are a reasonable and widely chosen option for the production of solar panels due to their durability, resistance to corrosion, thermal conductivity, and aesthetic attractiveness.

Send your message to us

300 Serises Stainless Steel Suppliers in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords