Carbon Steel Sheet Plate High Quality A36

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description of steel plate:

Our products into high-strength low-alloy steel plate, carbon structural steel plate, alloy structural steel plate, boiler and pressure vessel steel plate, bridge steel plate, structural steel plate, shipbuilding steel plate and marine oil platform steel plate, pipe steel plate, high strength and high toughness steel plate, mold plate, corrosion-resistant plate, Wear-resistand steel plate, composite plate with 12 major series.

2.Size range: Steel Plate width 300-5000mm, thickness 5-600mm, length 1000-18000mm.

Usage: (1).used for metallurgical, mechanical, electrical construction field

(2).used for ships, military (armored) Construction

(3).used for outside engineering, machine tool base, automobile rear of products

3.Standard: According to user requirements, can be delivered the following criteria: National standards, the metallurgical industry, the American ASTM, ASME standards, Japanese JIS, German DIN, British BS, European EN, the international ISO standards and the standards specific board.

4.Inspection Standard: In accordance with China (JB4730, GB/T2970), United States (A435, A577, A588), Japan (JISG0801, JISG0901), Germany (SEL072), British (BS5996), France (NFS04-305) and other domestic and international testing standard production test.

5.Data of steel sheet:

TYPE | STEEL sheet |

OUTER DIAMETER | 1000 1250 1500 1800MM |

WALL THICKNESS | 0.3-2.0MM |

THICKNESS TOLORANCE | +/- 002MM |

ZINC COATING | 60G-270G |

STANDARD | iso1461 |

MATERIAL | SPCC |

PACKING | WATERPROOF CLOTH FRISTLY, AND SURFACE TO BE VANISHED AND BE PACKED IN BUNDLES, WRAPPED WITH STEEL STRIP IN MINIMUM IN 5 POINTS, |

SURFACE TREATMENT | BRIGHT FINISHED, SLIT EDGE, OILED |

DELIVERY TIME | ACCORDING TO THE QUANTITY, LESS THAN 20 DAYS |

MOQ | 25TONS |

PRODUCTIVITY | 6000 TONS PER MONTH |

REMARK | ANTI CORRSION AND HIGH TEMPERATURE RESISTANG WITH BLACK PAINTING ALL THE PRODUCTION PROCESS ARE MADE UNDER THE ISO 9001-2000 STRICTLY |

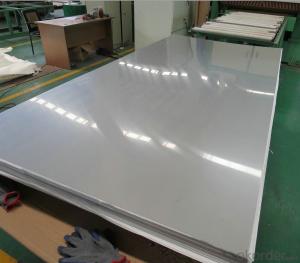

6.Image of steel sheet:

7.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How to introduce carbon steel plate?

- According to the use of carbon steel can be divided into carbon structural steel, carbon tool steel and free cutting steel structure three, carbon structural steel and steel construction project is divided into two kinds of structural steel and machinery manufacturing; (2) by refining methods can be divided into open hearth steel, steel converter; (3) according to the method of desoxydation can be divided into boiling Teng steel (F), steel (Z) and SEMIKILLED steel (b) and special steel (TZ); (4) according to the carbon content of the steel can be divided into low carbon steel (WC = 0.25%), carbon steel (WC0.25% - 0.6%) and high carbon steel (WC>0.6%); (5) according to the the quality of the steel can be divided into ordinary carbon steel (carbon steel with phosphorus, sulfur, high quality carbon steel (P), low sulfur and high quality steel (P), lower sulfur) and super high quality steel.

- Q: What does "Z" mean to the performance of steel?

- To apply for Z steel plate thickness and subjected to tensile load on just the thickness direction has the performance requirements, it is in a certain level of structural steel (called parent steel) on the basis of the special treatment (such as calcium treatment, vacuum degassing, argon stirring etc.) and proper heat treatment steel.

- Q: What are the common lengths of steel sheets?

- Common lengths of steel sheets can vary depending on the specific application and industry requirements. However, some commonly available lengths include 8 feet (2.44 meters), 10 feet (3.05 meters), and 12 feet (3.66 meters).

- Q: Can the steel sheets be easily drilled or machined?

- Steel sheets can be drilled or machined with ease. The versatility of steel allows for easy manipulation using a range of tools and techniques. Drilling and machining steel sheets is a widely practiced method in industries like construction, manufacturing, and engineering. By employing the appropriate equipment and expertise, one can create holes, mold the material, or attain precise dimensions required for a specific purpose.

- Q: Can steel sheets be used in high-temperature applications?

- Yes, steel sheets can be used in high-temperature applications due to their excellent heat resistance properties. Steel sheets are commonly used in industries such as automotive, aerospace, and manufacturing where high temperatures are encountered.

- Q: Can steel sheets be used for soundproofing or insulation?

- While steel sheets can indeed be utilized for soundproofing or insulation, they do not possess the same level of efficacy as materials specifically engineered for these functions. The density and sound- and heat-blocking capabilities inherent in steel sheets do confer some natural soundproofing and insulating properties to a certain extent. Nevertheless, their efficiency pales in comparison to those of dedicated soundproofing materials like acoustic panels or fiberglass insulation. To enhance the soundproofing or insulation attributes of a structure, steel sheets can be employed as an additional layer, but for optimal outcomes, they should be combined with other materials.

- Q: Can steel sheets be used for radiation shielding?

- Yes, steel sheets can be used for radiation shielding. Steel is a commonly used material for radiation shielding due to its high density and ability to absorb and scatter radiation. When it comes to protecting against radiation, the thickness of the shield is crucial. Thicker steel sheets are more effective in blocking radiation, as they have a higher absorption capacity. Steel sheets can be utilized for various applications such as in nuclear power plants, medical facilities, industrial radiography, and even in the construction of protective barriers in areas with high levels of radiation.

- Q: What is the average cost of stainless steel sheets?

- The average cost of stainless steel sheets can vary depending on various factors such as the grade of stainless steel, the thickness of the sheets, the size of the sheets, and the supplier. On average, stainless steel sheets can range in price from $30 to $300 per sheet. Lower-grade stainless steel sheets tend to be more affordable, while higher-grade ones can be more expensive. Additionally, thicker sheets are generally more costly than thinner ones due to the increased amount of material used. It is important to consider these factors and shop around to find the best price and quality that suits your specific needs.

- Q: Can steel sheets be used in the energy sector?

- Yes, steel sheets can be used in the energy sector for various applications such as in construction of power plants, transmission towers, wind turbines, and oil and gas pipelines. Steel sheets are known for their strength, durability, and ability to withstand harsh environments, making them suitable for use in the energy industry.

- Q: How do you calculate the square footage of a ton of steel?

- The width of the sheet is 500~1500 mm; the thickness is 600~3000 mm. According to the type of steel sheet, ordinary steel, stainless steel, alloy steel, spring steel, stainless steel, tool steel, heat-resistant steel, bearing steel, silicon steel and industrial pure iron sheet; according to professional use, with drums board, enamel board, bulletproof plate; surface coating and plating, plating with zinc thin plate, tin plate, plating lead sheet, plastic composite plate

Send your message to us

Carbon Steel Sheet Plate High Quality A36

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords