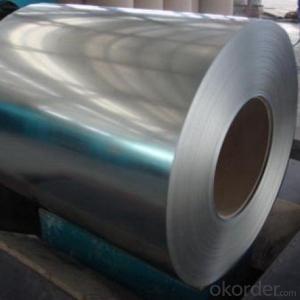

300 Series Hot Rolled Stainless Steel NO.1 Finish

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

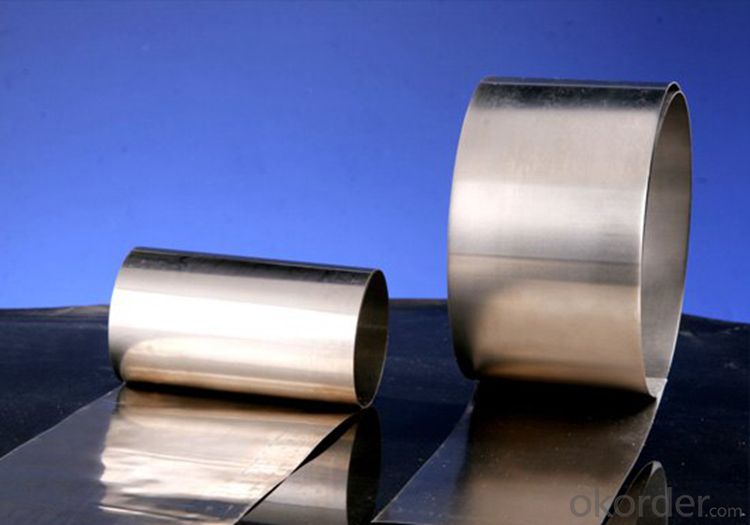

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment&Delivery

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Application of Stainless Steel Coils

(1) Boiler heat exchanger,

(2) Chemical industries,

(3) Hardware fields,

(4) Construction material,

(5) Kitchen utensils,

(6) Building construction,

(7) Medical equipment,

(8) chemical tank,

(9) pipe etc

Detail picture for Stainless Steel

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: How do you prevent crevice corrosion in stainless steel sheets?

- To prevent crevice corrosion in stainless steel sheets, there are a few key measures that can be taken: 1. Proper design and fabrication: Ensure that the stainless steel sheets are designed and fabricated with smooth surfaces and minimal crevices. This will reduce the potential for stagnant solution entrapment and minimize the risk of crevice corrosion. 2. Regular cleaning and maintenance: Regularly clean the stainless steel sheets to remove any debris or contaminants that can promote crevice corrosion. This can be done using mild detergents or specialized stainless steel cleaners. 3. Avoid exposure to corrosive environments: Limit the exposure of stainless steel sheets to corrosive environments, such as those containing chloride ions (e.g., saltwater). If exposure is unavoidable, consider applying protective coatings or using higher-grade stainless steel alloys that are more resistant to crevice corrosion. 4. Control the environment: Maintain proper environmental conditions, such as controlling temperature, humidity, and pH levels, to minimize the risk of crevice corrosion. Monitoring and controlling these factors can help create a less conducive environment for corrosion to occur. 5. Regular inspections and maintenance: Conduct regular inspections to identify any signs of crevice corrosion, such as discoloration, pitting, or rough surfaces. If any corrosion is detected, take immediate action to remove it and repair the affected area. By implementing these preventive measures, you can significantly reduce the risk of crevice corrosion in stainless steel sheets, ensuring their longevity and performance.

- Q: Can stainless steel sheets be used for flooring?

- Yes, stainless steel sheets can be used for flooring. Stainless steel is a durable and corrosion-resistant material that can withstand heavy foot traffic and provide a sleek and modern look to the flooring.

- Q: Can stainless steel sheets be used for wire mesh?

- Yes, stainless steel sheets can be used for wire mesh. Stainless steel is a versatile material that is commonly used in various applications due to its durability, corrosion resistance, and strength. When stainless steel sheets are processed into wire mesh, they can provide a strong and reliable mesh structure. Stainless steel wire mesh is often used in industries such as construction, agriculture, mining, and filtration, among others. It is known for its ability to withstand harsh environments, resist rust and corrosion, and maintain its structural integrity over time.

- Q: What are the applications of stainless steel sheets in the automotive industry?

- Due to their advantageous properties, stainless steel sheets are extensively utilized in the automotive industry. These sheets play a vital role in various automobile components, contributing to the overall performance, durability, and aesthetics of vehicles. A key application of stainless steel sheets in the automotive industry is seen in the manufacturing of exhaust systems. With its high resistance to corrosion and heat, stainless steel proves to be an ideal material for exhaust pipes. These sheets can endure the elevated temperatures generated by the engine, ensuring the longevity and reliability of the exhaust system. Furthermore, stainless steel sheets find use in the production of automotive body panels. They offer exceptional strength and rigidity, enabling the creation of lightweight yet robust body parts. The corrosion resistance of stainless steel is also advantageous, as it guarantees the long-lasting quality of the body panels, even in harsh weather conditions. Moreover, stainless steel sheets are employed in the fabrication of fuel tanks and other fluid storage components. The corrosion resistance and ability to withstand high pressure make stainless steel a suitable material for such applications. The integration of stainless steel in fuel tanks ensures their leak-free and durable nature, ultimately enhancing safety and longevity. Additionally, stainless steel sheets are utilized in the manufacture of various interior and exterior trim parts. These include decorative elements like grilles, trims, and accents, which enhance the vehicle's aesthetics. The ability of stainless steel to be polished and finished to a high shine adds an element of elegance and sophistication to the car's design. To summarize, stainless steel sheets have multiple applications within the automotive industry. They are utilized in exhaust systems, body panels, fuel tanks, and trim parts, among others. The exceptional properties of stainless steel, including corrosion resistance, heat resistance, and strength, greatly contribute to the overall performance, durability, and aesthetics of automobiles.

- Q: Can stainless steel sheets be formed into complex shapes?

- Complex shapes can indeed be formed from stainless steel sheets. Stainless steel is renowned for its exceptional formability and versatility, establishing it as a highly utilized material across numerous industries. It can be readily manipulated through various fabrication techniques like bending, rolling, stamping, and deep drawing, facilitating the creation of intricate shapes with utmost precision and accuracy. Furthermore, stainless steel possesses remarkable ductility, enabling it to endure substantial deformation while retaining its mechanical properties and structural integrity. Consequently, it is frequently favored for applications necessitating intricate and tailored designs, including architectural structures, automotive components, kitchen appliances, and medical devices.

- Q: What are the benefits of using embossed stainless steel sheets?

- Embossed stainless steel sheets offer several benefits. Firstly, they provide a highly durable and long-lasting solution due to the strength and corrosion resistance of stainless steel. Additionally, the embossed pattern adds a unique aesthetic appeal, enhancing the overall look and feel of any space. Furthermore, the embossing helps to hide scratches and fingerprints, making the surface more forgiving and easier to maintain. Lastly, the texture created by embossing adds grip, making it suitable for applications where slip resistance is required, such as flooring or staircases.

- Q: How do you drill holes in stainless steel sheets?

- To achieve accurate and clean results, it is necessary to follow specific steps and use the right tools when drilling holes in stainless steel sheets. Here is a detailed guide on how to accomplish this task: Step 1: Gather the required tools, including a drill machine, suitable drill bits for stainless steel (cobalt or carbide are recommended), a center punch, safety goggles, work gloves, and a clamp or vise to secure the stainless steel sheet. Step 2: Select the appropriate drill bit. Since stainless steel is a tough material, regular drill bits may not be effective. Instead, opt for cobalt or carbide drill bits that are specifically designed for cutting through hard metals. Step 3: Mark the hole position by using a center punch to create a small indentation at the exact spot where you intend to drill. This will prevent the drill bit from slipping when starting the hole. Step 4: Firmly secure the stainless steel sheet using a clamp or vise on a workbench or surface. This will prevent any movement during drilling and ensure precise and clean holes. Step 5: Prioritize safety by wearing safety goggles and work gloves to protect your eyes and hands from metal debris and sharp edges. Step 6: Begin drilling by placing the drill bit on the marked indentation and applying gentle pressure to start the hole. Use a lower speed setting on your drill machine to prevent overheating, gradually increasing the pressure as you continue drilling. Step 7: Apply cutting fluid or lubricant on the drill bit while drilling to reduce friction and heat buildup. This will extend the life of the drill bit and prevent discoloration or warping of the stainless steel sheet due to excessive heat. Step 8: Monitor the drilling progress and adjust the speed and pressure accordingly. It is crucial to maintain a steady pace and avoid applying excessive force to prevent drill bit breakage or damage to the stainless steel sheet. Step 9: Periodically stop drilling to remove metal debris from the hole, ensuring that it does not clog and that the hole remains clean. Step 10: Once the desired hole size is achieved, slowly withdraw the drill bit from the stainless steel sheet. Use a file or deburring tool to smooth out any rough edges around the hole. By following these steps and utilizing the appropriate tools, you can successfully drill precise and clean holes in stainless steel sheets. Remember to take your time, prioritize safety, and properly maintain your tools for optimal results.

- Q: What is the minimum thickness available for stainless steel sheets?

- The minimum thickness available for stainless steel sheets can vary depending on the specific grade and manufacturing capabilities, but it is typically around 0.4 millimeters (0.0157 inches) or even thinner.

- Q: Can stainless steel sheets be used for medical instruments?

- Yes, stainless steel sheets can be used for medical instruments. Stainless steel is a popular choice for medical instruments due to its excellent corrosion resistance, durability, and ease of sterilization. It is non-reactive, which means it does not leach any harmful substances into the body during medical procedures. Stainless steel sheets are used to manufacture various medical instruments such as surgical tools, implants, dental instruments, and diagnostic equipment. The smooth surface of stainless steel sheets also makes them easy to clean and maintain, which is crucial for maintaining sterility in medical settings. Overall, stainless steel sheets are a reliable and widely used material for manufacturing medical instruments.

- Q: Can stainless steel sheets be used in the automotive industry?

- Yes, stainless steel sheets can be used in the automotive industry. Stainless steel is often used due to its high strength, corrosion resistance, and durability. It is used for various components such as exhaust systems, body panels, frames, and interior trim.

Send your message to us

300 Series Hot Rolled Stainless Steel NO.1 Finish

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords