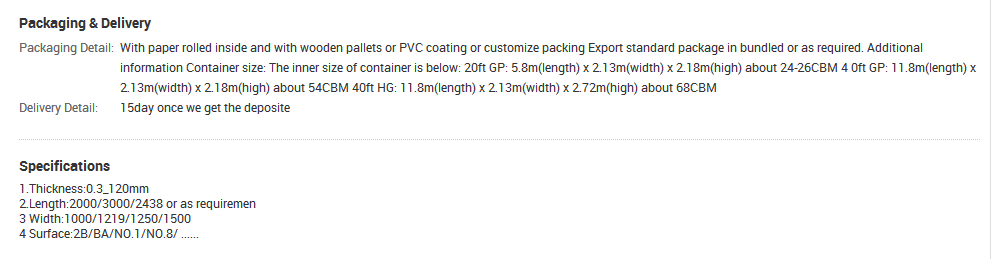

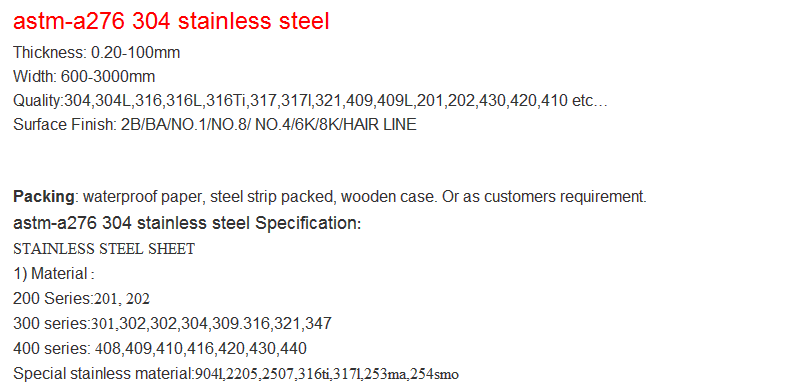

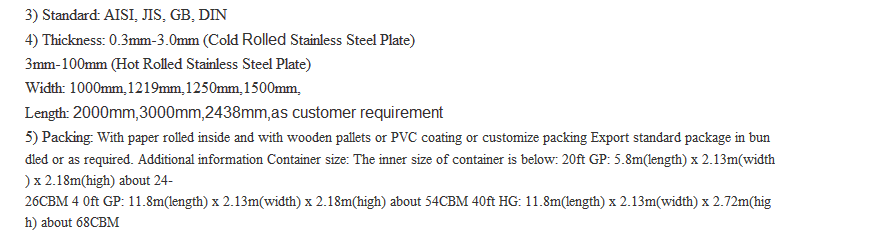

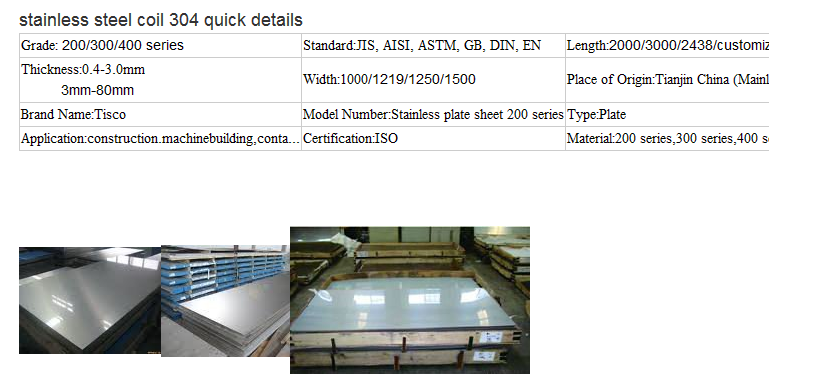

276 304 stainless steel,stainless steel sheet,stainless steel plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: What are the different types of stainless steel pipe bends?

- There are several different types of stainless steel pipe bends, including 45-degree, 90-degree, and 180-degree bends. Additionally, there are short radius and long radius bends, as well as U-bends and J-bends. These variations allow for flexibility in designing and connecting stainless steel piping systems to fit specific needs and spatial constraints.

- Q: Can stainless steel pipes be used for drinking water supply?

- Yes, stainless steel pipes can be used for drinking water supply. Stainless steel is a highly durable and corrosion-resistant material, making it a suitable choice for transporting drinking water safely and hygienically. Unlike other materials, stainless steel pipes do not leach harmful chemicals or contaminants into the water, maintaining its quality and purity. Additionally, stainless steel pipes are resistant to bacterial growth, which further ensures the safety of the drinking water.

- Q: Are stainless steel pipes suitable for fire sprinkler systems?

- Indeed, fire sprinkler systems find stainless steel pipes to be a suitable choice. The durability and longevity of stainless steel, owing to its remarkable resistance to corrosion, make it an ideal material for pipe systems. This corrosion resistance ensures that the pipes will not weaken or deteriorate over time, thus guaranteeing the fire sprinkler system's dependability and effectiveness. Furthermore, stainless steel pipes possess outstanding heat resistance, a crucial attribute in fire protection systems. They can endure high temperatures without warping or melting, thereby ensuring that the pipes will not fail in the event of a fire emergency. All in all, stainless steel pipes offer the requisite strength, durability, and heat resistance needed in fire sprinkler systems, rendering them a suitable choice for such applications.

- Q: Can stainless steel pipes be threaded?

- Yes, stainless steel pipes can be threaded. Threading is a process of creating internal or external threads on a material, which allows for easy connection and assembly with other components. Stainless steel is a versatile material that can undergo threading processes, including both internal and external threading. Threading stainless steel pipes can be done using various methods such as manual threading, machine threading, or even by using specialized threading tools. Threading stainless steel pipes provides a secure and reliable connection, making it suitable for various applications in industries such as plumbing, oil and gas, construction, and more.

- Q: What is the difference between electropolished and passivated stainless steel pipes?

- Electropolished and passivated stainless steel pipes are both surface treatments used to enhance the corrosion resistance and aesthetic appearance of stainless steel. However, there are some key differences between the two processes. Electropolishing is an electrochemical process that selectively removes a thin layer of material from the stainless steel surface. This process helps to remove impurities, contaminants, and embedded particles, resulting in a smooth and clean surface. Electropolishing also improves the microfinish of the stainless steel, reducing surface roughness and enhancing the overall appearance. This process can also improve the corrosion resistance of stainless steel by creating a passive chromium oxide layer on the surface. On the other hand, passivation is a chemical process that involves the application of an acid-based solution to the stainless steel surface. This solution helps to remove iron contaminants and other foreign substances from the surface, leaving behind a clean and passive layer of chromium oxide. Passivation helps to enhance the corrosion resistance of stainless steel by promoting the formation of a stable and protective oxide layer. In summary, electropolishing is an electrochemical process that removes a thin layer of material to create a smooth and clean surface, while passivation is a chemical process that removes contaminants and promotes the formation of a protective oxide layer. Both processes contribute to improving the corrosion resistance and aesthetics of stainless steel pipes, but they differ in the method used to achieve these results.

- Q: Can stainless steel pipes be used for sewage and wastewater systems?

- Yes, stainless steel pipes can be used for sewage and wastewater systems. Stainless steel is known for its excellent corrosion resistance, making it highly suitable for applications involving water and sewage. It is resistant to rust, corrosion, and chemical reactions, which ensures a longer lifespan and reduces the need for frequent replacements. Stainless steel pipes also have a smooth surface that prevents the accumulation of debris and facilitates easy cleaning. Additionally, stainless steel is non-porous, preventing the growth of bacteria and fungi, making it hygienic and suitable for sewage and wastewater systems. Its durability, reliability, and resistance to harsh environmental conditions make stainless steel pipes a popular choice for these applications.

- Q: Can stainless steel pipes be insulated with polyvinylidene fluoride?

- Yes, stainless steel pipes can be insulated with polyvinylidene fluoride (PVDF). PVDF is a highly durable and temperature-resistant polymer that is commonly used for insulation purposes. It has excellent chemical resistance, UV stability, and flame retardant properties, making it suitable for insulating stainless steel pipes in various applications. PVDF insulation can help prevent heat loss or gain, protect against corrosion, and provide additional mechanical protection to the stainless steel pipes.

- Q: Can stainless steel pipes be wrapped with fiberglass insulation?

- Yes, stainless steel pipes can be wrapped with fiberglass insulation.

- Q: What is the difference between seamless and welded stainless steel pipes?

- The manufacturing process and resulting characteristics are what set seamless and welded stainless steel pipes apart. Seamless pipes are made by piercing a solid billet or ingot, heating it to a high temperature, and then rolling it into a hollow cylindrical shape. This ensures a smooth and uniform surface with no seams or joints. Seamless pipes are known for their higher strength and better corrosion resistance compared to welded pipes. They are the preferred choice for applications involving high pressure or temperature, as their seamless nature makes them more reliable and less prone to leaks. On the other hand, welded pipes are created by joining two or more pieces of steel using different welding techniques. This process introduces a seam or weld line along the length of the pipe. Welded pipes can be produced continuously or intermittently, depending on the specifications required. Although they may have slightly lower strength and corrosion resistance than seamless pipes, advancements in welding technology have greatly improved their quality and performance. Welded pipes are generally more cost-effective and commonly used in applications with lower pressure or temperature requirements. In conclusion, the differences between seamless and welded stainless steel pipes stem from their manufacturing processes and resulting characteristics. Seamless pipes offer higher strength, better corrosion resistance, and are preferred for high-pressure or temperature applications. Welded pipes are more cost-effective, commonly used for lower-pressure or temperature applications, and have seen significant enhancements in quality and performance. Ultimately, the choice of pipe type depends on the specific needs of the application and cost considerations.

- Q: Can stainless steel pipes be used for power generation applications?

- Yes, stainless steel pipes can be used for power generation applications. Stainless steel is a popular choice for pipes in power generation due to its high corrosion resistance, durability, and strength. It can withstand high temperatures and pressures, making it suitable for various power generation processes such as thermal power plants, nuclear power plants, and hydroelectric power plants. Stainless steel pipes are commonly used in power generation applications for several reasons. Firstly, stainless steel has excellent resistance to corrosion, both from high-temperature steam and chemicals commonly used in power generation processes. This resistance ensures that the pipes remain intact and reliable over a long period of time, reducing maintenance and replacement costs. Secondly, stainless steel pipes are known for their durability and strength. They can withstand the high pressures and temperatures generated during power generation without deforming or breaking. This is crucial for ensuring the safety and efficiency of power generation systems. Furthermore, stainless steel is also highly resistant to scaling and fouling, which can occur in power generation applications due to the presence of impurities in water or steam. The smooth surface of stainless steel pipes helps minimize the buildup of deposits, ensuring efficient heat transfer and preventing clogging or blockage. Lastly, stainless steel pipes are compatible with a wide range of power generation fuels, including coal, natural gas, oil, and renewable energy sources. They can handle the corrosive effects of these fuels and maintain their structural integrity. In summary, stainless steel pipes are well-suited for power generation applications due to their corrosion resistance, durability, strength, and compatibility with various fuels. They offer a reliable and long-lasting solution for transporting fluids and gases in power generation systems.

Send your message to us

276 304 stainless steel,stainless steel sheet,stainless steel plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords