SUS 304 Stainless Steel Sheet & stainless steel plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications:

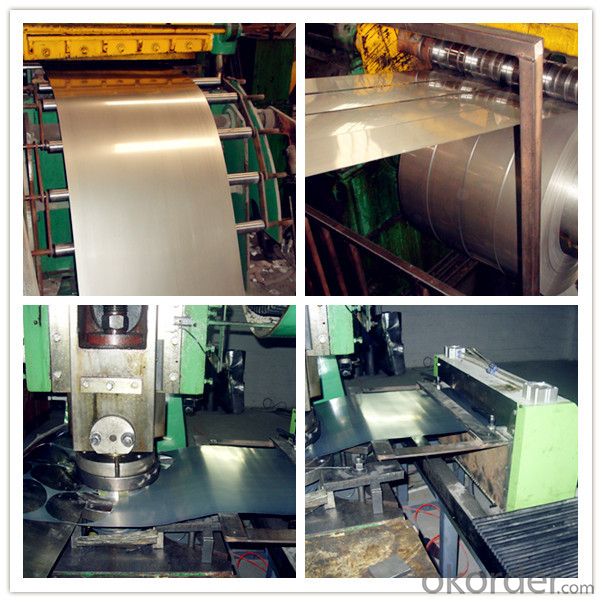

1) Surface: NO.1, 2B, BA, NO.3, NO.4, HL, NO.8 and so on.

2) Thickness: 0.3 to 80 mm

3) Width: 31 to 2000mm

4) Grade: 304, 304L, 316L, 321, 310S, 430, 409L, 201 etc.

Specification:

Type1 | Stainless steel coil |

Grade | 304,304L,316L,430,201,321,409L, etc. |

Thickness | 3.0-14mm(Hot rolled),0.3-6.0mm(cold rolled) |

Width | 1000/1219/1250/1500/1524/1800/2000mm or customized |

Diameter | 508mm,610mm |

Type2 | Stainless steel plate/sheet |

Grade | 304,304L,316L,430,201,321,409L, etc. |

Thickness | 3.0-80mm(Hot rolled),0.3-6.0mm(cold rolled) |

Width | 1000/1219/1250/1500/1524/1800/2000mm or customized |

Length | 500-6000 or customized |

Type 3 | Stainless steel strip |

Material | 304,304L,316L,430,201,321,409L, etc. |

Thickness | 3.0-8mm(Hot rolled),0.3-3.0mm(cold rolled) |

Width | 41-2000mm(Hot rolled),6-1550mm(cold rolled) |

Surface finish | NO.1, 2B, BA, NO.3, NO.4, HL, NO.8 and so on. |

Standard | ASTM,AISI, EN , DIN, JIS, GB, etc. |

Origin | BAOSTEEL,TISCO,TTSS,BAOXIN etc. |

Application range | Foodstuff, Gas, metallurgy, biology, electronic, chemical industry, petroleum, auto industry, beer tank. |

boiler, nuclear energy, Medical equipment, fertilizer etc. | |

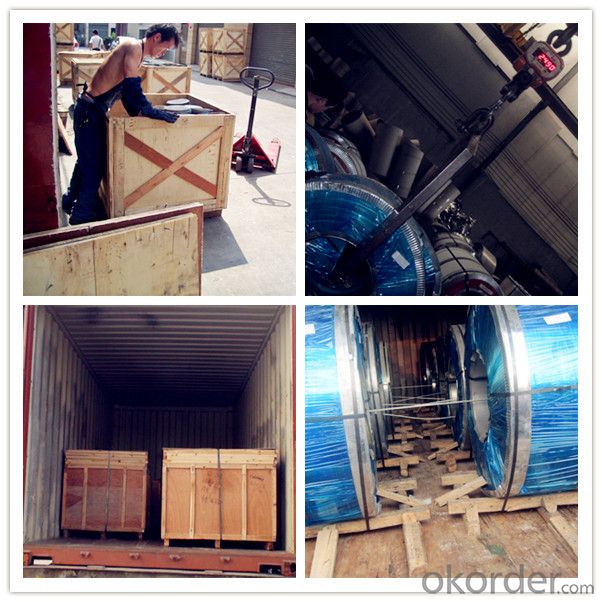

Packing | Standard export sea-worthy packing in wooden or squire pipe pallet. |

Delivery time | Normally 15-20 days(Stock),45-60 days (Production) |

Productivity | 5000-6000 tons/month |

Note | We can produce other standard as the customers’ requirement |

Trade details:

1. Mills origin: BAOSTEEL, TISCO, TTSS, BAOXIN, LISCO, ZPSS etc.

2. Delivery time: 10-20 days (Stock), 45-60days (production)

3. Payment: 30%- 100% T/T in advance, the rest balance against copy of B/L within 5 days or irrevocable LC at sight.

4.Shipment: Within 60 days or earlier as possible supplier can do to Shanghai port after the arrival of 30%TT deposit, or after the signature of contract if LC

5. Loading port: Shanghai/Ningbo, China.

6. Packing: As per export standard packing of Manufacturer, safety for transportation by container (suitable for container-carriage, protect against shock and discharging)

7. Inspection: Mills original material test report.

8. Quantity tol: +/-10% in total quantity and amount.

9. MOQ: 2ton per thickness.

More Products

Manufacting

| Q&A corrugated steel sheet | |||||||

| 1 | Q: WHAT ARE YOUR MAIN PRODUCT? | ||||||

| A:We are specializing in providing cold rolled 201/410/430 Stainless Steel Coil / Stainless Steel Strip /Stainless Steel Sheet / Stainless Steel Plate, Stainless Steel Circle, Stainless Steel tube/ Stainless Steel Pipe Sheets. | |||||||

| 2 | Q: WHAT ARE YOUR ADVANTAGES? | ||||||

| 1. We have a strict quality control from production to delivery. 2. We use advanced system and tool to improve working efficiency and control every step. 3. We have a specialized team in dealing with all the documents required by customers. We aim to zero error to save money and time for client. | |||||||

| 3 | Q: CAN I GET FREE SAMPLE? | ||||||

| A: YES. We can provide free sample. But we are not responsible for the delivery fee . | |||||||

Packing & Loading

- Q: Can stainless steel sheets be used for backsplashes?

- Yes, stainless steel sheets can be used for backsplashes.

- Q: Are stainless steel sheets suitable for heat transfer equipment?

- Stainless steel sheets are indeed a suitable option for heat transfer equipment. The reason lies in the remarkable thermal conductivity properties of stainless steel, enabling it to effectively transfer heat between different mediums. Its ability to endure high temperatures without warping or deforming makes it particularly well-suited for heat transfer applications. Moreover, stainless steel's resistance to corrosion guarantees the equipment's durability and longevity. Additionally, its hygienic qualities make it a fitting choice for industries such as food and pharmaceuticals, where cleanliness is of utmost importance. In conclusion, stainless steel sheets are a dependable and efficient selection for heat transfer equipment.

- Q: Can stainless steel sheets be used for medical implants or devices?

- Stainless steel sheets have the potential to serve as medical implants or devices. Thanks to its exceptional corrosion resistance, strength, and biocompatibility, stainless steel is a frequently utilized material in medical implants and devices. Its applications encompass orthopedic implants (such as hip replacements and bone plates), surgical instruments, dental implants, and cardiovascular devices. By precisely fabricating stainless steel sheets into the required shape and size, durability and long-term functionality in diverse medical applications can be ensured. Moreover, the ease with which stainless steel can be sterilized renders it suitable for employment in medical settings.

- Q: How do you prevent pitting or crevice corrosion on stainless steel sheets?

- To prevent pitting or crevice corrosion on stainless steel sheets, certain measures can be taken. First, ensuring proper cleaning and maintenance is crucial. Regularly cleaning the stainless steel sheets with mild detergent and water, followed by thorough rinsing and drying, helps remove any contaminants that can lead to corrosion. Additionally, avoiding exposure to corrosive substances like chloride-based cleaners or harsh chemicals is important. Applying a protective coating or passivating the stainless steel surface can also provide an extra barrier against corrosion. Passivation involves treating the stainless steel with a mild oxidizing agent to promote the formation of a passive oxide layer, which enhances the metal's resistance to corrosion. Proper design and installation practices are equally vital. Avoiding the use of dissimilar metals in contact with stainless steel sheets and ensuring proper sealing and gasketing in joints or crevices can prevent crevice corrosion. Adequate ventilation and avoiding stagnant conditions can also help minimize corrosion risks. Regular inspection and maintenance are necessary to identify and address any signs of corrosion promptly. This includes checking for signs of pitting or crevices, addressing any damage or scratches, and promptly repairing or replacing any corroded areas.

- Q: What is the difference between cold rolled and hot rolled stainless steel sheets?

- The manufacturing process and resulting surface finish are the primary factors that differentiate cold rolled and hot rolled stainless steel sheets. Cold rolled stainless steel sheets are made by rolling the steel at room temperature. This involves passing the steel through a series of rollers to reduce its thickness and achieve the desired shape. Cold rolling results in a smoother and more refined surface finish, with fewer surface defects and a tighter tolerance on thickness. Additionally, the process enhances the strength and hardness of the stainless steel sheet. On the other hand, hot rolled stainless steel sheets are produced by heating the steel above its recrystallization temperature and then rolling it through a series of rollers. This method is typically carried out at a higher temperature than cold rolling, resulting in a rougher surface finish. Hot rolling is commonly used for thicker sheets and leads to a more variable thickness and hardness compared to cold rolling. Regarding applications, cold rolled stainless steel sheets are commonly utilized in industries that require precise measurements, such as automotive, aerospace, and construction. The smoother surface finish makes them suitable for applications where aesthetics and surface quality are important. Conversely, hot rolled stainless steel sheets are often employed in applications that prioritize strength and durability, such as structural components in buildings, industrial machinery, and equipment. In conclusion, the main distinctions between cold rolled and hot rolled stainless steel sheets lie in the manufacturing process, resulting surface finish, and their respective applications. Cold rolled sheets offer a smoother surface finish and tighter thickness tolerance, while hot rolled sheets have a rougher surface finish and are more suitable for applications requiring strength and durability.

- Q: What is the elongation percentage of stainless steel sheets?

- The elongation percentage of stainless steel sheets can vary depending on the specific grade and thickness of the material. Generally, stainless steel sheets have a moderate elongation percentage, typically ranging from 40% to 60%. However, certain grades of stainless steel with higher nickel content, such as austenitic stainless steel, can exhibit greater elongation percentages, often exceeding 60%. It is important to note that elongation percentage is a measure of the material's ability to deform plastically before fracturing, indicating its ductility.

- Q: How do stainless steel sheets differ from other types of sheets?

- Stainless steel sheets set themselves apart from other types of sheets primarily due to their composition and distinctive properties. Unlike sheets made from materials like aluminum, brass, or copper, stainless steel sheets are manufactured using an alloy of iron, chromium, and other elements. The corrosion resistance of stainless steel sheets is one of the key distinctions. By adding chromium to the alloy, a passive layer forms on the surface of the sheet, safeguarding it against rust and corrosion. As a result, stainless steel sheets are highly durable and well-suited for diverse applications, particularly in environments exposed to moisture, chemicals, or extreme temperatures. Another factor that distinguishes stainless steel sheets is their strength and toughness. They possess exceptional mechanical properties, including high tensile strength, which renders them resistant to deformation and damage. Consequently, stainless steel sheets are more dependable and long-lasting compared to other sheet types. Moreover, stainless steel sheets offer an extensive range of aesthetic possibilities. They can be easily customized with various finishes, such as brushed, polished, or embossed, to achieve different appearances and textures. This versatility in design makes stainless steel sheets a popular choice in architectural, interior design, and decorative applications. Furthermore, stainless steel sheets boast excellent hygiene properties, qualifying them for use in the food and healthcare industries. They are easy to clean, non-porous, and non-reactive, preventing the growth of bacteria and ensuring the safety and cleanliness of the surfaces they cover. In conclusion, the unique characteristics of stainless steel sheets, including their corrosion resistance, strength, durability, aesthetic options, and hygiene properties, distinguish them from other sheet types. As a result, stainless steel sheets serve as a versatile and reliable choice for a wide range of applications across various industries.

- Q: What are the different types of edge finishes for stainless steel sheets?

- There are several different types of edge finishes that can be applied to stainless steel sheets. These finishes are designed to enhance the appearance and functionality of the edges while also providing protection against corrosion and damage. 1. Mill Finish: This is the most basic type of edge finish, where the edges are left as they come from the mill. It is a straight, unfinished edge without any additional treatment or polishing. 2. Deburred Edge: In this type of finish, the rough edges are smoothed out and deburred using abrasive materials. This helps to eliminate sharp edges and burrs, making the sheet safer to handle and preventing potential injuries. 3. Rounded Edge: A rounded edge finish involves milling or machining the edges to create a curved or rounded profile. This type of finish is commonly used in applications where safety is a concern, as it reduces the risk of cuts or injuries caused by sharp edges. 4. Beveled Edge: A beveled edge finish involves cutting or grinding the edges at an angle to create a sloped or chamfered profile. This type of finish is often used for aesthetic purposes, as it adds a decorative element to the sheet and can create a smooth transition between different surfaces. 5. Polished Edge: In this type of finish, the edges of the stainless steel sheet are polished to a high shine using abrasive materials or polishing compounds. This produces a smooth, reflective surface that enhances the overall appearance of the sheet and gives it a more finished look. 6. Brushed Edge: A brushed edge finish involves applying a brushed texture to the edges of the stainless steel sheet. This is achieved by using abrasive materials or brushes to create a consistent pattern of fine lines or scratches. The brushed edge finish can provide a unique and contemporary look to the sheet. These different types of edge finishes for stainless steel sheets offer various benefits and can be chosen based on the specific requirements of the application. Whether it's for safety, aesthetics, or functionality, selecting the right edge finish can greatly enhance the performance and visual appeal of stainless steel sheets.

- Q: Can stainless steel sheets be used for elevator interiors?

- Elevator interiors can indeed incorporate stainless steel sheets. Stainless steel proves to be a favored material for elevator interiors due to its durability, aesthetic appeal, and low maintenance. Its resistance to corrosion, scratches, and stains makes it an excellent choice for heavily frequented areas such as elevators. Moreover, stainless steel sheets can be customized to meet specific elevator design requirements and are available in a range of finishes, including brushed, mirrored, or patterned, offering a sleek and contemporary appearance. Furthermore, stainless steel is effortless to clean and sanitize, a crucial consideration in public spaces like elevators where hygiene is of utmost importance. In summary, stainless steel sheets present a versatile and pragmatic solution for elevator interiors.

- Q: Can stainless steel sheets be used for electrical enclosures?

- Yes, stainless steel sheets can be used for electrical enclosures. Stainless steel is a highly durable and corrosion-resistant material that provides excellent protection for electrical components. It has high strength and can withstand harsh environmental conditions, making it suitable for both indoor and outdoor applications. Additionally, stainless steel has good conductivity and can dissipate heat efficiently, which is crucial for maintaining proper temperatures within the enclosure. This makes stainless steel sheets a reliable choice for electrical enclosures, offering long-lasting performance and protection for the enclosed electrical equipment.

Send your message to us

SUS 304 Stainless Steel Sheet & stainless steel plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords