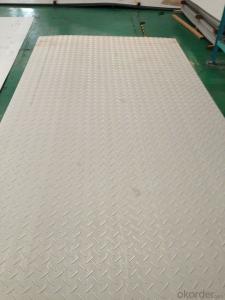

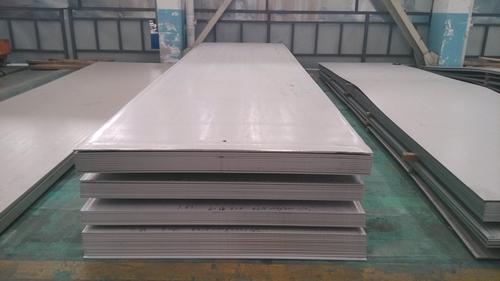

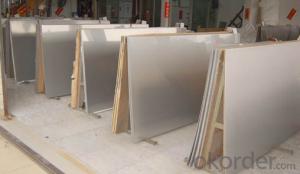

Stainless Steel 304 sheet with top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q: What is the difference between 304H and 304L stainless steel pipes?

- The main difference between 304H and 304L stainless steel pipes lies in their carbon content. 304H has a higher carbon content, which gives it improved high temperature strength and resistance to sensitization. On the other hand, 304L has a lower carbon content, making it more resistant to corrosion in certain environments.

- Q: Are stainless steel pipes suitable for compressed air systems?

- Yes, stainless steel pipes are suitable for compressed air systems. Stainless steel has excellent corrosion resistance, high strength, and can withstand high-pressure conditions, making it a reliable choice for transporting compressed air. Additionally, stainless steel pipes are durable and have a long lifespan, minimizing the need for frequent replacements.

- Q: Can stainless steel pipes be used for chemical storage tanks?

- Yes, stainless steel pipes can be used for chemical storage tanks. Stainless steel is highly resistant to corrosion and can withstand the harsh chemicals found in many industrial processes. Additionally, stainless steel pipes are durable, easy to clean, and have a long lifespan, making them a suitable choice for chemical storage applications.

- Q: What are the different standards and specifications for stainless steel pipes?

- There are several different standards and specifications for stainless steel pipes, depending on their intended use and the industry they are being used in. Some common standards include ASTM A312/A312M, which covers seamless, welded, and heavily cold worked austenitic stainless steel pipes; ASTM A358/A358M, which specifies electric-fusion-welded austenitic chromium-nickel stainless steel pipes; and ASTM A790/A790M, which covers seamless and welded ferritic/austenitic stainless steel pipes. Additionally, there are standards specific to different countries, such as EN 10216-5 in Europe and JIS G3459 in Japan. These standards outline the requirements for dimensions, material composition, mechanical properties, and other characteristics of stainless steel pipes.

- Q: What is the difference between seamless and SAW stainless steel pipes?

- Seamless and SAW (Submerged Arc Welding) stainless steel pipes find utility in various industries for the transportation of fluids or gases, but they possess certain distinct dissimilarities. 1. Manufacturing Process: The primary discrepancy resides in their manufacturing processes. Seamless stainless steel pipes emerge from the piercing of a solid billet, shaping it into a hollow tube. Conversely, SAW pipes result from the welding of multiple layers of steel plates together, employing a submerged arc welding technique. 2. Appearance: Seamless pipes boast a sleek and polished surface, imparting them with a more visually pleasing aspect. Conversely, SAW pipes display discernible welding seams, which can manifest internally or externally. 3. Strength and Durability: Seamless pipes generally exhibit superior strength and durability compared to SAW pipes. The absence of welding seams in seamless pipes eradicates potential weak points, rendering them less prone to failure under elevated pressure or extreme temperatures. 4. Size Range: Seamless pipes offer a broader spectrum of sizes, encompassing both small and large diameters. SAW pipes, limited by the welding process, are primarily employed for larger diameter pipes. 5. Cost: In terms of cost-effectiveness, SAW pipes typically hold an advantage over seamless pipes. The manufacturing process of SAW pipes entails the welding of multiple plates, which is less expensive than the process of creating a seamless pipe from a solid billet. 6. Applications: Seamless pipes find common usage in industries where high pressure and corrosion resistance are imperative, such as oil and gas, petrochemical, and power generation. SAW pipes, owing to their larger size range and cost-effectiveness, are frequently utilized in infrastructure projects like water supply, sewage systems, and construction. In conclusion, the principal discrepancies between seamless and SAW stainless steel pipes lie in their manufacturing process, appearance, strength, size range, cost, and applications. The choice between the two hinges upon the specific requirements of the project and the desired characteristics of the pipe.

- Q: Can stainless steel pipes be used for agricultural irrigation systems?

- Indeed, agricultural irrigation systems can utilize stainless steel pipes. With its exceptional durability and resistance to corrosion, stainless steel proves to be an appropriate material for a wide range of purposes, including agricultural irrigation. Its remarkable ability to withstand rust and corrosion, even when faced with moisture, chemicals, and fertilizers commonly employed in irrigation systems, is well-known. Furthermore, stainless steel pipes possess the capability to endure high-pressure water flow, enabling them to efficiently deliver water to crops. Notably, stainless steel is environmentally conscious, being entirely recyclable, which renders it a sustainable option for agricultural irrigation systems.

- Q: Can stainless steel pipes be used for marine applications?

- Yes, stainless steel pipes can be used for marine applications. Stainless steel is known for its corrosion resistance, making it an ideal material for use in marine environments where there is constant exposure to saltwater and high levels of humidity. Stainless steel pipes are resistant to rust and corrosion, ensuring their durability and longevity in marine applications. They are commonly used for various purposes in the marine industry, such as piping systems, exhaust systems, and structural components. Additionally, stainless steel pipes can withstand extreme temperatures and pressures, making them suitable for the demanding conditions often encountered in marine applications.

- Q: What is the external coating used for stainless steel pipes?

- The external coating used for stainless steel pipes can vary, but common options include epoxy, polyethylene, or polypropylene coatings.

- Q: Can stainless steel pipes be used in the food processing industry?

- Yes, stainless steel pipes can be used in the food processing industry. Stainless steel is a popular choice for use in food processing due to its many beneficial properties. Firstly, stainless steel is resistant to corrosion, which is essential in an environment where food and liquids are constantly being processed and handled. Additionally, stainless steel is easy to clean and maintain, which is crucial in food processing to ensure hygiene and prevent contamination. Stainless steel pipes also have high strength and durability, allowing them to withstand the demanding conditions of the food processing industry. Moreover, stainless steel is non-reactive, meaning it does not interact chemically with food or ingredients, ensuring that the quality and taste of the processed products are not affected. Overall, stainless steel pipes are an excellent choice for the food processing industry due to their corrosion resistance, cleanliness, durability, and non-reactive properties.

- Q: Are stainless steel pipes resistant to crevice corrosion?

- Stainless steel pipes are generally known for their resistance to crevice corrosion. This is due to the presence of a significant amount of chromium in stainless steel, which creates a passive oxide layer on the material's surface. This oxide layer acts as a protective barrier, preventing the entry of corrosive substances, including crevices. However, it is important to consider that the resistance to crevice corrosion can vary based on the grade and composition of stainless steel used, as well as the environmental conditions the pipes are exposed to. Therefore, it is advisable to carefully choose the appropriate grade of stainless steel for the specific application and environment to ensure the best possible defense against crevice corrosion.

Send your message to us

Stainless Steel 304 sheet with top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords