Steel Flats 304 Stainless Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

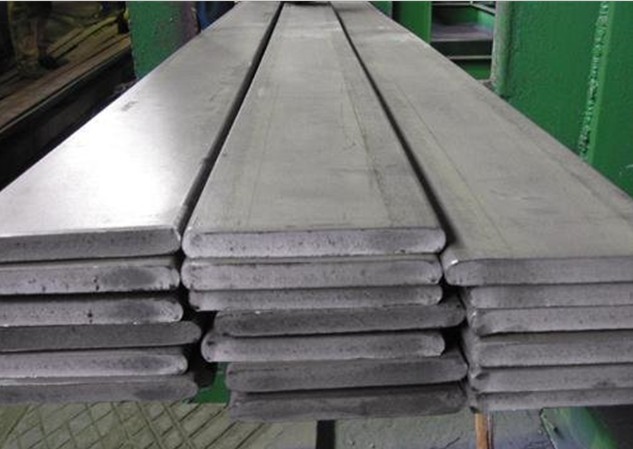

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

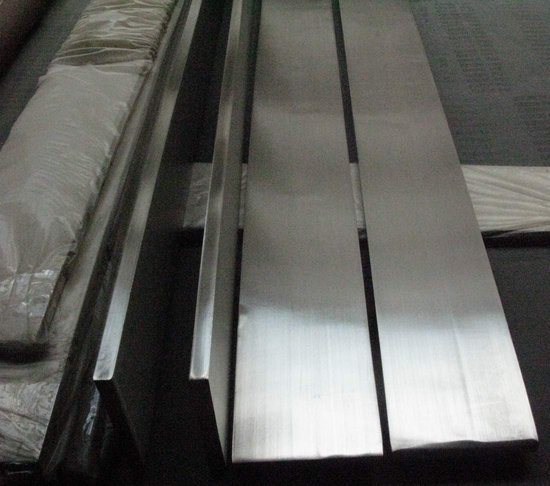

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

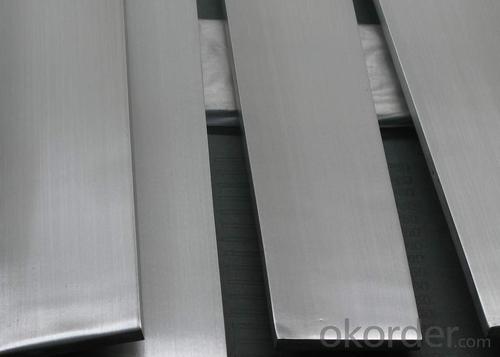

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q: Can stainless steel pipes be used for dairy industries?

- Yes, stainless steel pipes can be used for dairy industries. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for the sanitary requirements of the dairy industry. It is widely used in the production, processing, and transportation of milk and other dairy products due to its hygienic properties and ease of cleaning.

- Q: Can stainless steel pipes be used for firefighting systems?

- Yes, stainless steel pipes can be used for firefighting systems. Stainless steel is a durable and corrosion-resistant material, making it suitable for various applications, including firefighting systems. Its resistance to heat, pressure, and chemicals makes it an ideal choice for transporting water, foam, or other fire suppression agents. Stainless steel pipes are also known for their high strength and ability to withstand extreme conditions, ensuring the reliability and longevity of the firefighting system. Additionally, stainless steel pipes have a smooth inner surface, minimizing friction loss and maximizing water flow, which is essential for effective firefighting operations. Overall, stainless steel pipes provide a safe and efficient solution for firefighting systems, offering reliable performance and durability in critical situations.

- Q: Are stainless steel pipes recyclable?

- Yes, stainless steel pipes are recyclable. Stainless steel is a highly sustainable material that can be recycled repeatedly without losing its properties or quality. Recycling stainless steel pipes helps conserve resources, reduce waste, and minimize environmental impact.

- Q: Can stainless steel pipes be used in the aerospace industry?

- Certainly! Stainless steel pipes have a wide range of applications in the aerospace industry due to their versatility and durability. With exceptional resistance to corrosion, high temperatures, and pressure, stainless steel is an ideal material for various aerospace systems like fuel, hydraulic, and air conditioning systems. Moreover, stainless steel pipes are commonly utilized in aircraft engines, ensuring optimal performance under extreme temperatures. Furthermore, their lightweight nature makes them particularly suitable for aerospace applications where weight reduction is crucial. In conclusion, stainless steel pipes not only meet the rigorous requirements and standards of the aerospace industry but are also extensively employed in various aircraft and spacecraft components.

- Q: What are the different types of stainless steel pipe fittings?

- Various piping systems commonly use several different types of stainless steel pipe fittings. Some of the most frequently used ones are: 1. Stainless Steel Elbows: These fittings alter the pipe's direction by either 90 degrees or 45 degrees. They come in various angles and sizes to accommodate the specific requirements of the piping system. 2. Stainless Steel Tees: Tees create a branch in the pipeline, enabling the fluid flow in multiple directions. They possess three openings, with one inlet and two outlets. 3. Stainless Steel Couplings: Couplings connect two pipes of the same diameter. They come in different variants, including full coupling (both ends are threaded), half coupling (only one end is threaded), and reducing coupling (for connecting pipes of different diameters). 4. Stainless Steel Reducers: Reducers join pipes of varying diameters. They are available in two types: concentric reducers (tapered on both ends) and eccentric reducers (tapered on one end only). 5. Stainless Steel Caps: Caps seal the end of a pipe and are commonly used when further extension of the pipe is unnecessary. 6. Stainless Steel Crosses: Crosses resemble tees but have four openings instead of three. They create a branch in the pipeline with multiple outlets. 7. Stainless Steel Unions: Unions connect two pipes without the need for threading. They offer a convenient way to disassemble and reassemble the pipes for maintenance or repairs. 8. Stainless Steel Nipples: Nipples are short pipe sections with male threaded ends. They extend a pipe or facilitate a connection between two female threaded fittings. It is important to note that these examples represent only a fraction of the diverse range of stainless steel pipe fittings available. The specific fitting required depends on factors such as the application, pipe size, and other considerations.

- Q: Can stainless steel pipes be used in the automotive industry?

- Yes, stainless steel pipes can be used in the automotive industry. Stainless steel is a highly durable and corrosion-resistant material, making it ideal for various applications in the automotive sector. Stainless steel pipes are commonly used in exhaust systems, where they can withstand high temperatures and resist the corrosive effects of gases and condensation. Additionally, stainless steel pipes are also used in fuel delivery systems, brake lines, and hydraulic systems, where their strength and resistance to corrosion are essential. Overall, stainless steel pipes offer excellent performance and longevity in the demanding conditions of the automotive industry.

- Q: How do you protect stainless steel pipes from external damage?

- To ensure the protection of stainless steel pipes from external damage, there are several steps that can be taken: 1. Applying a protective coating: To shield the stainless steel pipes from moisture, chemicals, and physical harm, consider utilizing a protective coating such as paint or epoxy. Select the coating based on the specific environment and potential risks in order to maximize protection. 2. Installation of pipe supports: Preventing excessive movement and vibration is crucial in avoiding damage over time. Properly install pipe supports using brackets, clamps, or hangers to securely hold the pipes in place and minimize the risk of external impacts causing harm. 3. Implementation of corrosion prevention measures: Although stainless steel pipes are resistant to corrosion, certain environments can still pose a threat. Regularly inspect the pipes for signs of corrosion and address any issues promptly. Utilize corrosion inhibitors or cathodic protection techniques to further safeguard the pipes from external damage. 4. Usage of protective guards or covers: In areas where the pipes are vulnerable to potential impacts or physical harm, the installation of protective guards or covers can provide an additional layer of defense. These guards can be made from materials like plastic or rubber and can be easily installed or removed as needed. 5. Implementation of proper handling and storage procedures: During transportation or storage, it is crucial to handle stainless steel pipes with care. Avoid dropping or dragging them and make sure they are stored in a clean, dry, and well-ventilated area to prevent moisture buildup and potential damage. By adhering to these measures, the lifespan of stainless steel pipes can be significantly prolonged, ensuring their functionality and protection against external damage.

- Q: What is the pressure rating of stainless steel pipes?

- The pressure rating of stainless steel pipes varies depending on their size, wall thickness, and the specific grade of stainless steel used. However, stainless steel pipes typically have high pressure ratings due to their excellent strength and corrosion resistance properties.

- Q: What are the temperature limitations of stainless steel pipes?

- The temperature limitations of stainless steel pipes typically depend on the grade of stainless steel being used. Generally, stainless steel pipes can withstand high temperatures, with some grades capable of operating at temperatures up to 1500°F (815°C). However, prolonged exposure to extremely high temperatures can cause stainless steel to lose its strength and corrosion resistance. It is important to consult the specific grade and manufacturer's recommendations to determine the temperature limitations for a particular stainless steel pipe.

- Q: How do you prevent discoloration in stainless steel pipes?

- To prevent discoloration in stainless steel pipes, there are several measures that can be taken: 1. Proper cleaning: Regularly clean the stainless steel pipes using mild soap or detergent and warm water. Avoid using harsh chemicals or abrasive cleaners that can damage the surface and cause discoloration. 2. Rinse thoroughly: After cleaning, make sure to rinse the pipes thoroughly with clean water to remove any residue or cleaning agents that may cause discoloration. 3. Avoid contact with corrosive substances: Keep stainless steel pipes away from direct contact with corrosive substances such as strong acids, alkaline solutions, or chlorides. These substances can lead to chemical reactions and cause discoloration. 4. Use protective coatings: Applying a protective coating, such as a clear lacquer or a special stainless steel protective spray, can help prevent discoloration by creating a barrier between the metal surface and the environment. 5. Control temperature: Excessive heat can cause discoloration in stainless steel pipes. It is important to control the temperature of the surrounding environment or the fluid passing through the pipes to prevent overheating. 6. Regular maintenance: Perform routine inspections and maintenance to identify any signs of discoloration or damage and address them promptly. This includes checking for leaks, corrosion, or any other factors that may contribute to discoloration. By following these preventive measures, you can significantly reduce the risk of discoloration in stainless steel pipes and maintain their aesthetic appeal and functionality for a longer period.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | China, East Asia, |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Steel Flats 304 Stainless Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords