stainless steel pipes

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipes

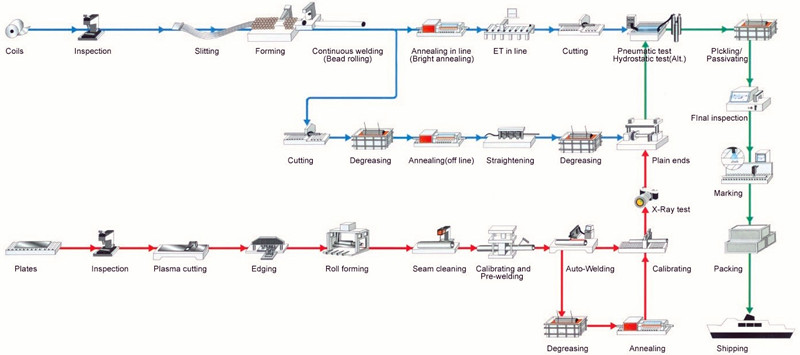

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:21.3*3.73mm or others

2.Surface:4k/6k//8k

3.Length:6m or as your requirement

A series of photos

A series of pictures

- Q: How do you prevent clogging in stainless steel pipes?

- To prevent clogging in stainless steel pipes, there are several measures that can be taken: 1. Regular maintenance: It is important to perform regular maintenance on stainless steel pipes to prevent clogging. This includes periodic inspection and cleaning to remove any build-up or debris that may lead to blockages. 2. Proper disposal of waste: Ensure that only appropriate materials are disposed of in the pipes. Avoid flushing or introducing items such as paper towels, sanitary products, or grease down the drain, as these can accumulate and cause clogs. 3. Use drain filters: Install drain filters or strainers at the openings of the pipes to catch any large particles or debris that could potentially cause clogs. These filters can be cleaned regularly or replaced as needed. 4. Avoid corrosive materials: Some chemicals or substances can corrode stainless steel pipes, leading to damage and potential clogs. It is important to avoid using corrosive materials in or near the pipes and to follow manufacturer guidelines for chemical usage. 5. Proper water flow: Ensure that there is adequate water flow through the pipes to prevent clogging. This can be achieved by running water regularly, especially for pipes that are not frequently used. 6. Consider water softeners: If the water supply is particularly hard, it may contain minerals that can build up and eventually clog the pipes. Installing a water softener can help reduce mineral deposits and prevent clogs. 7. Seek professional help: If you experience persistent clogging or are unsure of how to prevent it, it is recommended to consult with a professional plumber. They can assess the situation, provide guidance on preventive measures, and address any existing clogs effectively. By following these preventive measures, you can minimize the risk of clogs in stainless steel pipes and ensure the smooth operation of your plumbing system.

- Q: Can stainless steel pipes be threaded?

- Yes, stainless steel pipes can be threaded. Threading is a process of creating internal or external threads on a material, which allows for easy connection and assembly with other components. Stainless steel is a versatile material that can undergo threading processes, including both internal and external threading. Threading stainless steel pipes can be done using various methods such as manual threading, machine threading, or even by using specialized threading tools. Threading stainless steel pipes provides a secure and reliable connection, making it suitable for various applications in industries such as plumbing, oil and gas, construction, and more.

- Q: What is the difference between electropolished and passivated stainless steel pipes?

- Electropolished and passivated stainless steel pipes are both surface treatments used to enhance the corrosion resistance and aesthetic appearance of stainless steel. However, there are some key differences between the two processes. Electropolishing is an electrochemical process that selectively removes a thin layer of material from the stainless steel surface. This process helps to remove impurities, contaminants, and embedded particles, resulting in a smooth and clean surface. Electropolishing also improves the microfinish of the stainless steel, reducing surface roughness and enhancing the overall appearance. This process can also improve the corrosion resistance of stainless steel by creating a passive chromium oxide layer on the surface. On the other hand, passivation is a chemical process that involves the application of an acid-based solution to the stainless steel surface. This solution helps to remove iron contaminants and other foreign substances from the surface, leaving behind a clean and passive layer of chromium oxide. Passivation helps to enhance the corrosion resistance of stainless steel by promoting the formation of a stable and protective oxide layer. In summary, electropolishing is an electrochemical process that removes a thin layer of material to create a smooth and clean surface, while passivation is a chemical process that removes contaminants and promotes the formation of a protective oxide layer. Both processes contribute to improving the corrosion resistance and aesthetics of stainless steel pipes, but they differ in the method used to achieve these results.

- Q: What wire is used for welding of 316 stainless steel line?

- Apply A102 (E308-16) or A202 (E316-16) welding rodAttention should be summarized as follows: welding rod should be dry, low current, fast welding speed, interlayer temperature of about 60 degrees, intermittent welding, in order to avoid intergranular corrosion, immediately after welding water cooling.

- Q: How do stainless steel pipes compare to polyvinyl chloride pipes?

- Stainless steel pipes have a higher durability and can withstand higher pressures and temperatures compared to polyvinyl chloride (PVC) pipes. Additionally, stainless steel pipes are resistant to corrosion, making them suitable for a wide range of applications, including in harsh environments. On the other hand, PVC pipes are lightweight, easy to install, and more affordable. However, they are not as durable as stainless steel and have limitations in terms of pressure and temperature resistance. Ultimately, the choice between stainless steel and PVC pipes depends on the specific requirements and conditions of the project.

- Q: 316 stainless steel pipe wall mirror polishing, the smaller the roughness, the better.

- Steel pipe is purchased separately, and then polished to find manufacturers alone, can meet the requirements,The cost is very high. To tell you the truth, I don't know.Specializing in sanitary stainless steel tube, stainless steel tube, precision sanitary stainless steel tube and stainless steel tube precision tube production and sales, the main material: stainless steel material: 0Cr18Ni9 (304 stainless steel tube) and 00Cr19Ni10 (304L stainless steel tube (316), stainless steel tube), 00Cr17Ni14Mo2 (GB 316L stainless steel tube), the products are widely used in instrumentation pharmaceutical machinery, food machinery, auto parts, pneumatic components, beverage, beer, drinking water, air purification and biological engineering and other fields.

- Q: What is the difference between seamless and hot-finished stainless steel pipes?

- Seamless and hot-finished stainless steel pipes are both used in various industrial applications, but they have some key differences. The main difference between seamless and hot-finished stainless steel pipes lies in their manufacturing process. Seamless pipes are made by piercing a solid steel billet to form a hollow tube without any seams or joints. This process ensures a consistent wall thickness throughout the pipe and a smooth interior surface. On the other hand, hot-finished pipes are created by heating a solid billet and then rolling it to form a tube shape. This rolling process can result in a seam or weld line along the length of the pipe. Another significant difference between seamless and hot-finished stainless steel pipes is their dimensional accuracy and surface finish. Seamless pipes are known for their high dimensional accuracy and excellent surface finish, making them suitable for applications where a precise fit and smooth flow are critical, such as in the pharmaceutical or food processing industries. Hot-finished pipes, although generally not as precise in terms of dimensions and surface finish, are more cost-effective and widely used in applications where tight tolerances are not required, such as in structural or construction projects. In terms of strength and durability, both seamless and hot-finished stainless steel pipes offer excellent performance. However, seamless pipes tend to have higher strength due to their manufacturing process, as there are no weak points or potential areas of failure like welded seams. This makes seamless pipes preferred in applications that require high pressure or corrosion resistance, such as in oil and gas pipelines or chemical processing plants. In summary, the main differences between seamless and hot-finished stainless steel pipes lie in their manufacturing process, dimensional accuracy, surface finish, and strength. Seamless pipes are produced without any seams or welds, resulting in superior dimensional accuracy and surface finish, making them suitable for precise applications. On the other hand, hot-finished pipes are more cost-effective and widely used in applications where tight tolerances are not crucial. Both types of pipes offer excellent strength and durability, but seamless pipes are generally preferred in high-pressure or corrosive environments.

- Q: Are stainless steel pipes suitable for drinking water applications?

- Stainless steel pipes are indeed appropriate for drinking water purposes. Thanks to their exceptional durability and resistance to corrosion, stainless steel proves to be an outstanding selection for the transportation of drinking water. It refrains from releasing any hazardous elements into the water and resists rust and scaling, thereby guaranteeing the cleanliness and safety of the water for consumption. Moreover, stainless steel pipes are effortlessly cleaned and maintained, thus enhancing the hygiene of the water supply. Furthermore, the prolonged lifespan and dependability of stainless steel pipes render them a cost-efficient resolution for drinking water applications.

- Q: Are stainless steel pipes suitable for underground sewage systems?

- Yes, stainless steel pipes are suitable for underground sewage systems. Stainless steel pipes are known for their durability, strength, and resistance to corrosion, making them an excellent choice for underground applications. They have a long lifespan and can withstand the harsh conditions typically found in sewage systems, such as exposure to moisture, chemicals, and varying temperatures. Additionally, stainless steel pipes have a smooth interior surface, which helps prevent the buildup of debris or waste, reducing the risk of clogs or blockages. Overall, stainless steel pipes provide a reliable and long-lasting solution for underground sewage systems.

- Q: How do you prevent pitting corrosion in stainless steel pipes?

- To prevent pitting corrosion in stainless steel pipes, several measures can be taken. First, choosing the right grade of stainless steel with high corrosion resistance, such as 316 or 904L, is important. Maintaining a passive oxide layer on the surface of the pipes through regular cleaning and passivation is also crucial. Additionally, avoiding exposure to chloride-containing environments and using coatings or linings to protect the pipe's surface can help prevent pitting corrosion. Regular inspection and maintenance to identify any potential corrosion sites and taking prompt corrective actions are essential in preventing pitting corrosion in stainless steel pipes.

Send your message to us

stainless steel pipes

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords