201 Stainless Steel Flat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1 Ton

8. Delivery: within 20 days

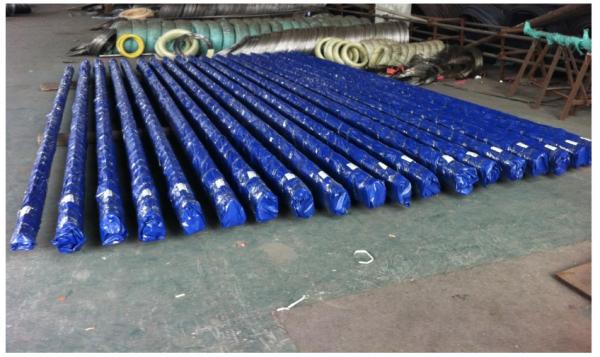

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Size |

Thickness (mm) | |||||||||||

|

Width (mm) |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

14 |

16 |

20 |

25 |

30 |

|

Theoretical Weight (kg/m) | ||||||||||||

|

10 |

0.238 |

0.32 |

0.4 |

0.48 |

0.63 |

|

|

|

|

|

|

|

|

15 |

0.36 |

0.48 |

0.59 |

0.71 |

0.95 |

1.19 |

|

|

|

|

|

|

|

20 |

0.476 |

0.63 |

0.79 |

0.95 |

1.27 |

1.59 |

1.9 |

|

|

|

|

|

|

25 |

0.585 |

0.79 |

0.99 |

1.19 |

1.59 |

1.98 |

2.38 |

|

|

|

|

|

|

30 |

0.714 |

0.95 |

1.19 |

1.43 |

1.9 |

2.38 |

2.85 |

3.33 |

3.81 |

4.75 |

5.948 |

|

|

40 |

0.952 |

1.27 |

1.59 |

1.9 |

2.54 |

3.17 |

3.81 |

4.44 |

5.08 |

6.34 |

7.93 |

9.52 |

|

50 |

1.19 |

1.59 |

1.98 |

2.38 |

3.17 |

3.97 |

4.76 |

5.55 |

6.34 |

7.93 |

9.91 |

11.9 |

|

60 |

1.428 |

1.9 |

2.38 |

2.85 |

3.81 |

4.76 |

5.71 |

6.66 |

7.61 |

9.52 |

11.9 |

14.27 |

|

70 |

|

2.22 |

2.78 |

3.33 |

4.44 |

5.55 |

6.66 |

7.77 |

8.88 |

11.1 |

13.88 |

16.65 |

|

80 |

|

|

3.17 |

3.81 |

5.08 |

6.34 |

7.61 |

8.88 |

10.15 |

12.69 |

15.86 |

19.03 |

|

90 |

|

|

3.57 |

4.28 |

5.71 |

7.14 |

8.56 |

9.99 |

11.42 |

14.27 |

17.84 |

21.41 |

|

100 |

|

|

3.97 |

4.76 |

6.34 |

7.93 |

9.52 |

11.1 |

12.69 |

15.86 |

19.82 |

23.79 |

|

110 |

|

|

|

5.23 |

6.98 |

8.72 |

10.47 |

12.21 |

13.96 |

17.45 |

21.81 |

26.17 |

|

120 |

|

|

|

5.71 |

7.61 |

9.52 |

11.42 |

13.32 |

15.23 |

19.03 |

23.79 |

28.55 |

|

130 |

|

|

|

6.19 |

8.25 |

10.31 |

12.37 |

14.43 |

16.49 |

20.62 |

25.77 |

30.93 |

|

140 |

|

|

|

6.66 |

8.88 |

11.1 |

13.32 |

15.54 |

17.76 |

22.2 |

27.76 |

33.31 |

|

150 |

|

|

|

7.14 |

9.52 |

11.9 |

14.27 |

16.65 |

19.03 |

23.79 |

29.74 |

35.69 |

|

160 |

|

|

|

7.61 |

|

12.69 |

15.23 |

17.76 |

20.3 |

25.38 |

31.72 |

38.06 |

|

170 |

|

|

|

|

|

13.48 |

16.18 |

18.87 |

21.57 |

26.96 |

33.7 |

40.44 |

|

180 |

|

|

|

|

|

14.27 |

17.13 |

19.98 |

22.84 |

28.55 |

35.69 |

42.82 |

- Q: What is the difference between annealed and pickled stainless steel pipes?

- Annealed stainless steel pipes and pickled stainless steel pipes both undergo different processes that affect their properties and appearance. Annealing is a heat treatment process that involves heating the stainless steel pipes to a specific temperature and then slowly cooling them. This process helps to relieve internal stresses and improve the ductility and toughness of the material. Annealed stainless steel pipes are usually softer and more malleable, making them easier to work with during fabrication and installation. They also tend to have a smoother, more polished surface finish. On the other hand, pickling is a chemical process that removes surface impurities such as oxides, scales, and rust from stainless steel pipes. It involves immersing the pipes in an acid solution, typically a mixture of nitric and hydrofluoric acid, which dissolves the impurities. Pickling helps to restore the corrosion resistance of the stainless steel and leaves a clean, bright, and uniform surface finish. In summary, the main difference between annealed and pickled stainless steel pipes lies in the processes they undergo. Annealing improves the material's ductility and toughness, while pickling removes surface impurities and restores corrosion resistance. The choice between annealed and pickled stainless steel pipes depends on the specific requirements of the application, such as the desired mechanical properties and surface finish.

- Q: Can stainless steel pipes be insulated with neoprene?

- Yes, stainless steel pipes can be insulated with neoprene. Neoprene is a commonly used material for pipe insulation due to its excellent thermal properties and resistance to moisture. It provides effective insulation and protects against heat loss or condensation on stainless steel pipes.

- Q: What is the external protection used for stainless steel pipes?

- The external protection used for stainless steel pipes can vary, but it typically involves the application of coatings or paints that provide a barrier against corrosion and other environmental factors.

- Q: Can stainless steel pipes be used for solar power systems?

- Yes, stainless steel pipes can be used for solar power systems. Stainless steel is a commonly used material in solar power systems due to its durability, corrosion resistance, and high temperature tolerance. It is often used for the construction of solar water heaters, solar thermal collectors, and solar panel frames.

- Q: Stainless steel pipe is mainly used in what areas?

- The stainless steel pipe is a kind of economic section steel, is one of the most important products in the steel industry, which can be widely used in industrial and living decoration on the market, a lot of people for the production of staircase handrails, railings, window, furniture etc.. There are two kinds of materials, 201 and 304.

- Q: Can stainless steel pipes be insulated with PVC?

- No, stainless steel pipes cannot be insulated with PVC. PVC (polyvinyl chloride) is not suitable for insulating stainless steel pipes due to its lower temperature resistance. Stainless steel pipes are often used for high-temperature applications, and PVC insulation may not be able to withstand the heat without deforming or melting. It is recommended to use insulation materials specifically designed for high-temperature applications, such as mineral wool or fiberglass, which can provide better thermal protection for stainless steel pipes.

- Q: Can stainless steel pipes be used for chemical processing plants?

- Yes, stainless steel pipes can be used for chemical processing plants. Stainless steel is a popular choice for various industrial applications, including chemical processing, due to its excellent corrosion resistance properties. Chemical processing plants deal with various corrosive substances, such as acids, alkalis, and solvents, which can cause damage to ordinary steel pipes. However, stainless steel pipes are highly resistant to corrosion, making them suitable for handling aggressive chemicals and ensuring the safety and reliability of the plant. Additionally, stainless steel pipes can withstand high temperatures, pressure, and mechanical stresses, making them a durable and long-lasting choice for chemical processing plants.

- Q: Can stainless steel pipes be pressure tested?

- Yes, stainless steel pipes can be pressure tested. Pressure testing involves subjecting the pipes to a higher pressure than they would normally experience during normal operations to ensure their strength and integrity. Stainless steel is known for its durability and ability to withstand high-pressure conditions, making it suitable for pressure testing applications. The process involves filling the pipes with a liquid or gas and increasing the pressure to the desired level while monitoring for any leaks or failures. It is important to follow proper procedures and safety measures during pressure testing to ensure accurate results and prevent any potential hazards.

- Q: What is the standard size range for stainless steel pipes?

- The standard size range for stainless steel pipes varies depending on the industry and application. However, in general, stainless steel pipes are available in a wide range of sizes, starting from small diameters of around 0.5 inches (12.7 mm) to large diameters of up to 48 inches (1219 mm) or even larger in some cases. The wall thickness of stainless steel pipes can also vary, ranging from thin-walled pipes with a thickness of a few millimeters to heavy-walled pipes with thicknesses exceeding an inch. The specific size range for stainless steel pipes may be determined by factors such as the intended use, pressure requirements, and industry standards. It is important to consult relevant specifications and standards to determine the appropriate size range for a specific application.

- Q: Can stainless steel pipes be insulated with polyphthalamide?

- No, stainless steel pipes cannot be insulated with polyphthalamide.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | China, East Asia, |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

201 Stainless Steel Flat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords