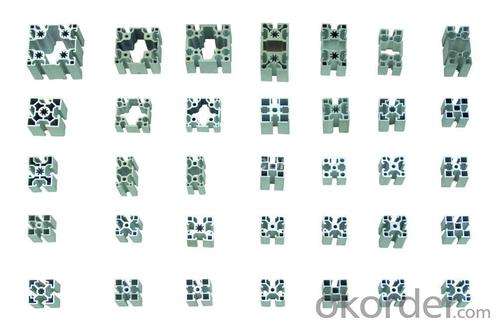

2020 T Slot Aluminum Profiles Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What are the different machining options for aluminum profiles?

- Some of the different machining options for aluminum profiles include milling, drilling, turning, and threading.

- Q: Can aluminum profiles be used in food-grade applications?

- Yes, aluminum profiles can be used in food-grade applications. Aluminum is a non-toxic, lightweight, and corrosion-resistant metal that is commonly used in the food industry. It is often used to fabricate food processing equipment, such as conveyor systems, tanks, shelves, and frames. Aluminum profiles can also be used in the construction of cleanrooms and other sanitary environments where food is processed or stored. Additionally, aluminum is easily cleaned and sanitized, making it a suitable material for food-grade applications. However, it is important to ensure that the aluminum profiles used are specifically designed for food-grade applications and comply with relevant regulations and standards to ensure the safety and quality of the food being processed or stored.

- Q: Including the element parameters, the price and the difference between 6063, what is the use and so on!How about 6060 100/ meters? How much is the strength? How much is the price more than 6063?

- It has many valuable features: 1. heat treatment, high impact toughness, plasticity of missing insensitive.2. has excellent heat, can be squeezed into a high speed complex structure. The hollow thin wall. Various profiles or forged into the complex structure of the forging, quenching temperature range quenching, low sensitivity, extrusion and forging after stripping, as long as the temperature is higher than the quenching temperature. The quenching method available water or water in thin walled parts (6.

- Q: Are aluminum profiles suitable for use in transportation vehicle bodies?

- Transportation vehicle bodies can benefit from the use of aluminum profiles. Aluminum is a material that is both lightweight and durable, making it suitable for this purpose. By utilizing aluminum profiles, vehicles can achieve a reduced weight, resulting in improved fuel efficiency and lower emissions. Furthermore, the excellent strength-to-weight ratio of aluminum profiles enables them to withstand the stresses and loads experienced by transportation vehicles. The corrosion resistance of aluminum is also advantageous, especially for vehicles exposed to harsh environmental conditions. Additionally, the flexibility of aluminum profiles allows for easy formation and shaping into complex designs, providing versatility in vehicle body construction. Overall, the adoption of aluminum profiles in transportation vehicle bodies presents numerous advantages, contributing to its widespread popularity in the industry.

- Q: Can aluminum profiles be used for creating lighting fixtures?

- Yes, aluminum profiles can be used for creating lighting fixtures. Aluminum is a popular material choice for lighting fixtures due to its lightweight nature, durability, and corrosion resistance. It is also easily shaped and machined, making it suitable for creating various designs and styles of lighting fixtures. Additionally, aluminum profiles can be powder-coated or anodized to enhance their appearance and provide additional protection against wear and tear. The versatility and aesthetic appeal of aluminum make it an ideal choice for creating lighting fixtures in a wide range of settings, including residential, commercial, and industrial applications.

- Q: How do you prevent galvanic corrosion in marine environments with aluminum profiles?

- One way to prevent galvanic corrosion in marine environments with aluminum profiles is by using sacrificial anodes made of a different, more active metal. These anodes, typically made of zinc or magnesium, are connected to the aluminum profiles and act as a sacrificial material that corrodes instead of the aluminum. This helps in protecting the aluminum profiles from galvanic corrosion. Additionally, proper insulation and coating of the aluminum profiles can also be effective in preventing direct contact with other metals and reducing the risk of galvanic corrosion.

- Q: Are aluminum profiles suitable for electrical grounding applications?

- Yes, aluminum profiles are suitable for electrical grounding applications. Aluminum is a highly conductive material, which means it can effectively carry electrical currents and dissipate any potential electrical charges. Aluminum profiles are commonly used in various electrical grounding systems, such as grounding bars, busbars, and grounding conductors. They provide a reliable and durable solution for creating a low-resistance path for electrical currents to flow safely to the ground. Additionally, aluminum profiles have excellent corrosion resistance properties, which further enhances their suitability for grounding applications in both indoor and outdoor environments.

- Q: This question asks about the characteristics of aluminum profiles, specifically whether they are lightweight and easy to handle.

- <p>Yes, aluminum profiles are known for their lightweight nature and ease of handling. They are made from aluminum, which is a lightweight metal with a low density. This makes aluminum profiles ideal for applications where weight is a concern, such as in construction, automotive, and aerospace industries. Additionally, their lightweight characteristic also contributes to their ease of handling, as they can be easily maneuvered and installed without requiring heavy machinery or excessive manpower.</p>

- Q: How do you clean and maintain aluminum profiles?

- To clean and maintain aluminum profiles, you can follow these simple steps: 1. Start by removing any loose dirt or debris from the surface of the aluminum profiles using a soft brush or cloth. 2. Prepare a cleaning solution by mixing mild dish soap or a non-abrasive cleaner with warm water. Avoid using harsh chemicals or abrasive cleaners as they can damage the aluminum finish. 3. Dip a soft cloth or sponge into the cleaning solution and gently scrub the aluminum profiles. Be sure to clean all the corners and crevices thoroughly. 4. Rinse the profiles with clean water to remove any soap residue. You can use a hose or a bucket of water for this step. 5. Dry the aluminum profiles completely using a soft, lint-free cloth. This will prevent water spots or streaks from forming. 6. For regular maintenance, you can use a specialized aluminum cleaner or polish to restore the shine and protect the surface. Follow the instructions on the product for best results. 7. It is important to avoid using abrasive scrubbers, steel wool, or harsh chemicals as they can scratch or damage the aluminum finish. Also, never use acidic cleaners or vinegar on aluminum as they can cause corrosion. 8. If you notice any scratches or minor damages on the aluminum profiles, you can use a touch-up paint specifically designed for aluminum to repair them. Follow the manufacturer's instructions for application. Remember, regular cleaning and maintenance will help preserve the appearance and longevity of your aluminum profiles.

- Q: Is aluminum alloy made of industrial aluminum?

- Aluminum profile is an applied product form of aluminum alloyAluminum is the aluminum bar through hot melt, extrusion, so as to obtain different cross-section of aluminum. The production process of aluminum profile mainly includes three processes: casting, extrusion and coloring.First, according to use can be divided into the following categories: 1. building doors and windows, aluminum doors and windows [1] (divided into two windows and curtain walls). Special aluminum radiator 2. CPU radiator 3. Aluminum Alloy shelf aluminum profile, the difference between them is that the different cross-sectional shapes. They are produced by hot melt extrusion 4.. Industrial aluminum: mainly used in automation equipment, sealing cover skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, electronic machinery industry and clean room with the majority!

Send your message to us

2020 T Slot Aluminum Profiles Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords