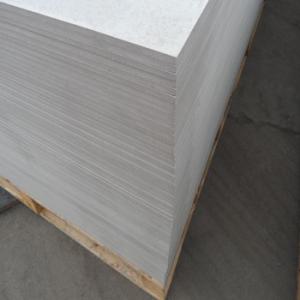

100 percent Without Asbestos Fiber Cement Board

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

100% Without Asbestos Fiber Cement Board

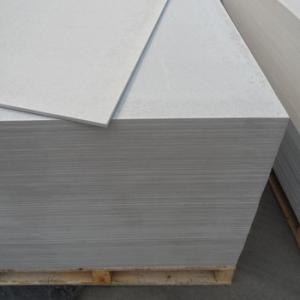

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

100% Without Asbestos Fiber Cement Board

Sound and Weather Resistant:

Karmeen fiber cement boards deliver optimal sound and weather insulation. Noise as well as changing weather conditions such as freeze / thaw, heat and water pose no threat to fiber cement board. The boards retain their shape at all times.

Low Maintenance:

The ability of the boards to resist mold and algae attacks is equally impressive. The result is a long-lived façade that saves you time and effort on inconvenient and costly repairs and repaints.

Non-combustible:

The boards are non-combustible, which is your guarantee for a safe building.

Easy Handling:

Karmeen fiber cement boards are flexible and easy to handle. They can be delivered cut to size, ready for installation. All this makes for lower construction costs, shorter construction times, and lower installed costs.

Board Edge:

Packaging Details:

Fumigation wooden pallets+PE cover + corner protector

100% Without Asbestos Fiber Cement Board

- Q: Can cement board be directly approved for cement?

- Do not join the sand and stone, is pure cement for cement paste

- Q: What is the material cut off both the fire and cheap

- The so-called Eide plate is a fiber-reinforced silicate plate (fiber cement board), the main raw material is cement, selected minerals, by the high pressure autoclave pressure. Ette board is a fiber reinforced cement plate with Fireproof. Good soundproofing, environmental protection, etc. It is 100% non-asbestos, and its waterproof performance is particularly superior to the bathroom for use as a partition, or an outdoor roof roof, or an external wall can be used in long-term damp The environment to maintain stability and stability.

- Q: I am making a custom kitchen island and I planned to tile the top of it. The top of the island is going to be made of thick plywood for strength and I was told by the man at the hardwood store where I bought all the supplies that I needed to place cement board down on the plywood before I placed the tile down. I had bought a trim to go around the table top, hoping that it would be flush with the tile once the time went into place, however using the cement board makes the trim flush with the cement board and after the tile is installed, it would be about 5 mm taller than the trim. Do I really need to use the cement board? Would it be a bad idea to place the tile and mortar directly on the plywood?

- keep in mind that although ceramic tile may be impervious to water and other fluids, the grout between the tile is not. if there is a chance that something will spill with any regularity it will get through the grout and you could end up with mold. this is not a situation into which you want to place your family. there is a product called tilebacker board which is available in 1/4 thickness. moisture will still get by the grout, but it will not be in contact with the wood structure which of course is organic.

- Q: the neighbor has a son and him and his friends constantly makes noise instigating trouble. I complain to the manager, it stops and than starts back up again a week later, so I rather put up something that can help

- Cement board will have little or no effect. Try some type of insulation or acoustical tile. Check with your local building supply. They will tell you what to use.

- Q: I've removed the old cement boards and I've put new ones up on the shower walls. My tile will not go to the ceiling. I'm at the step where I need to apply thin-set and tape to all of the cement board seems. What do I do at the seem that transitions from cement board to sheet rock?

- Yes tape those seams too. Make sure you nail the dry wall there too w/ a galvanized roofing nail. You may have to do so floating w/ thin set to get it flush but it ll work fine. The thin set , when gluing to dry wall needs to be a fresh batch or just a BIT looser and wetter since dry wall will absorb the thin set fast. Not wet wet just a bit looser. Any questions you can e mail me thru my avatar and check my qualifications there GL

- Q: How to choose their own materials made of steel structure compartment?

- First span a bit large, if not set up columns, then the second floor will not pile things, otherwise the consequences are very serious. 5.7 meters high, if there is no steel column, then the main beam must also be the smallest HN300 * 150, times beam election [12 Well, hidden in the main beam between the upper and lower flange plate, do a good job after the surface layer A little bit on the line.

- Q: Unfortinatly i already have the tile but i was hoping i could use self leveling cement then atattch the tile to it. is this even a posabilityor should i use hardyback board and if i do how can i atattch it to the cement

- I used the self leveling concrete mixture and sure enough, it worked great. Just make sure you do your prep work to ensure excellent results.

- Q: Home improvement wall is made of light steel keel + gypsum board, light steel keel + cement pressure plate is good or red brick light weight brick good?

- You can use the first program, light steel keel + sound-absorbing cotton, gypsum board, even if you want to hang TV no problem, which add skeleton on the line, so you can avoid the brick wall caused by the load-bearing problem.

- Q: What is the difference between cement calcium silicate board and cement fiberboard

- Cement fiberboard, also known as fiber cement board. Is based on siliceous, calcium material as the main raw material, adding plant fiber, through the pulp, copy, pressure, curing from a new type of building materials. After the high-pressure production of cement fiber board, also known as fiber cement pressure plate, its performance is better than the non-pressurized cement fiber board. Fiber cement board length and width of the standard specifications are 1200 * 2400mm and 1220 * 2440mm, manufacturers can basically customize the length of 2000-2500mm, width of 1000-1250mm within any specifications, other specifications can be cut on this basis. Fiber cement cement board thickness of 2.5,3,3.5,4,5,6,8,9,10,12,15,18,20,24,25,30,40,60,90 mm, the strength of the manufacturers Can be customized within any thickness of 2.5-100mm. Thickness of 4mm or less known as ultra-thin plate, 4-12mm become a conventional plate, 15-30mm and above known as thick plate, 30mm or more known as the thick plate. No small press manufacturers can only produce 6-12mm ordinary cement board; general manufacturers can only produce 4-12mm conventional board, thick plate to do well, thick plate can not do; thickness 2.5-100mm can do the manufacturers The country is small. Cement fiber board is widely used, the sheet can be used for ceiling materials, perforation can be used as sound-absorbing ceiling. Conventional board can be used for wall and / or decorative materials, thick plate can be used as LOFT steel floor board, attic board, external wall insulation board, wall panels and so on.

- Q: i live in a country where houses are made with bricks..but i made my house just like in USA , but there is one only problem i need cement board to finish the bathroom , since we don't have cement board here for sale , and i can't afford import from USA , i was wondering that i can make it , i'm sure that i can make it , but i just need to know how to prepare de cement i would be appreciated if anyone help me thanks

- Surely you must be able to purchase something equivalent? If Wonderboard is not available, how about Hardibacker? Or Cembonit?

Send your message to us

100 percent Without Asbestos Fiber Cement Board

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords