High Quality Asbestos Free Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction:

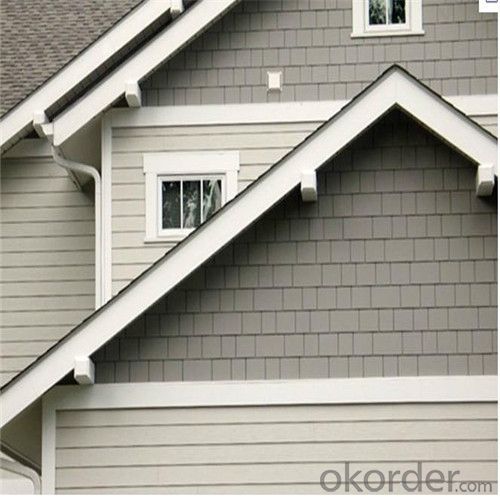

Sanle fiber cement board is made of high-grade cement and modified material, reinforced by natural fiber. Being processed by high pressure and high temperature advanced technologies, Sanle fiber cement board is a new building material with excellent performances.

Features

Fire Proof & Insulation

Class A non-inflammability, no toxic gas, low in perveance, good electric insulation material

Waterproof and Moisture Proof

In semi-outdoor area and under high temperature condition, performance of Sanle boards is stable and will not bend or deform.

Thermal Insulation and Sound Insulation

Low thermal conductivity, good heat insulation, high in density, sound proof

Light weight & High strength

Pressured by 5000-ton hydraulic machine, it is high in strength and light in weight. It is not easy to deform and bend, and good for flooring and roofing.

Easy installation

The installation of boards is dry operation, which is faster. It can be processed with ordinary wood working tool. The board is easy to be processed.

Economical and Good looking

The boards are light in weight. Together with the use of keels, they can save cost of construction and decoration. The painting is uniform, and the surface is smooth, making the exterior of buildings good-looking and attractive.

Safe and Harmless

Test result of Sanle boards is better than national radiation protection standards of building materials. The radiation from Sanle boards is equal to that from the lawn 20 meters away from the building. The lifespan of Sanle boards is very long, and they are resistant to acid and alkali, moisture and insects. The toughness and strength remains the same when time passes by. So they can be used for a long time.

Easy to install and easy to replace

Sanle boards can be drilled, cut, engraved, nailed, painted and covered by tiles or sticker when necessary..

Product parameters

Item | Unit | Requirement | ||||

Medium density | High density | |||||

Density | g/cm3 | 1.2<D≤1.5 | 1.5<D≤2.0 | |||

Water absorption | % | ≤30 | ≤25 | |||

Non-combustibility | GB 8624-2006, grade A | |||||

wet expansion | % | ≤0.25 | ||||

Beding strength | dry | MPA | Strength grade class III | 20 | Strength grade class IV | 24 |

Saturation with water | 12 | 14 | ||||

Applications

Exterior side boards, indoor partition walls, sound-proof ceiling, decoration boards, complex walls, outdoor billboards, division boards and floor boards

- Q: How to open the cement board

- With a diamond drill with a hollow drill bit, drilling rig than the pistol drill, with a diamond out of the empty outer tube structured, if not drill through the general drill concrete will not fall off their own need to use hairpin removed. Generally with plumbing plumbing and electrician, installation of air conditioning transfer machine punch there.

- Q: I want to put a cork bulletin board outside my store but it's a cement wall and I do not want to ruin the cement wall.

- I tapped some nails in. But I don't recommend it. It took a long time and you'll probably get charged for the damage it does to the paint. I found some sticky, puffy stuff from Duct Tape. It's double sided and it's waaaay sticky. For my heavier stuff I just doubled/tripled up and it hung right up. This is what I did for my full length mirror. Also they make those clear plastic holder things. I'm sorry, I'm not sure what they're called. But they have sticky on one side and you stick that to the wall and then there is a hook on the other side. They work great too and are cheap!

- Q: FC sound-absorbing board is what material

- FC board is made of pressurized fiber cement board as panel, with sandwich material in the factory processing production of composite wall panels.

- Q: Can tiles be attached to gypsum board?

- The use of tiles is generally in the kitchen, bathroom wall, ground, is to moisture. But the gypsum board itself can not be moisture, it is recommended not to use gypsum board tiles to achieve the purpose of waterproof moisture.

- Q: We have drywall in our kitchen that was painted with a smooth semi-gloss paint a good 8 yrs ago. We'd like to install 3x6 tumbled marble as a backsplash over the drywall. It's about 1/4 thick so probably slightly heavier than say, the tiny square glass tiles that come on a 12x12 netting. One person at the Home Depot said we could just sand and scrape up the drywall and then apply the thinset and install the marble. Another said we might want to use a cement backing. We aren't really DIYers and would so we don't want to create extra work with the cement backing if it isn't needed. That said, we don't want the drywall to start peeling and the marble tiles to start falling off after a short amount of time. Please advise. Thank you!

- I would recommend screwing wonder board over the drywall before putting the tile up. This will give you a long lasting application. It will not up your cost a whole lot and you will be much happier in the long run.

- Q: I need to fix a loom board cause one of the pegs broke we don't have superglue but we have vinyl cement can I use that?

- No. Honey has got it right. Wood glue (yellow) is the stuff to use. To do it properly, the broken peg needs to be drilled out and a new peg (dowel) needs to be put in. If a loom board is what I think it is, it is under stress (which is why it broke) and that joint needs to be as strong as possible.

- Q: The floor is on a raised foundation and we were told that there are 2 options: float it on thin set or use a concrete back board. Is there any perference to one over the other? I don't want the tile to crack.

- What is the floor material? Never heard of floating ceramic tiles. Wood? Use the backer board or use the old fashion method of 2 concret base. Concrete already? Lay right on top of it

- Q: I'm ready to tile my kitchen soon. My husband and I have torn up the carpet and 2 layers of linoleum, leaving only some leftover glue from the linoleum and the wood sub floor. Do we really need to lay cement board over the wood sub floor or can we just go ahead and tile right on the wood? (FYI: it will be either ceramic or porcelain tile)

- Yes, unfortunately you will. If you tile directly onto the sub floor, the tile is likely to develop cracks. The sub-floor is probably 3/4 material, so an additional 1/2 thick cement board should work.

- Q: Is there anything you can add to cement which will increase insulating power?I guess asbestos is illegal and I am not even sure how much it would work, but I was wondering if there isnt something out there that will add R value to cement if you add it to the mix without substantially reducing the strength of the cement itself.

- thickness...the thicker the concrete, the better it will insulate

- Q: How do fighters break ice, cement and wood blocks without breaking their hands, arms, legs and feet?

- strength of mind. cement, when hit correctly can break like a twig but it requires perfect breathing, a strong hand and a psychotic mind. u have to be completly nuts to try and break cement. breaking is is possible but......highly unlikely to happen. it would have to be a foot not a hand to break it. and i could break 10 boards if they each have a cm between each one. its about using the force of the first board to bread the others. so if your smart and good enough ur really only breaking half of them.. the pressure and weight is going to break the rest of them.

Send your message to us

High Quality Asbestos Free Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords