Asbestos Free Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction:

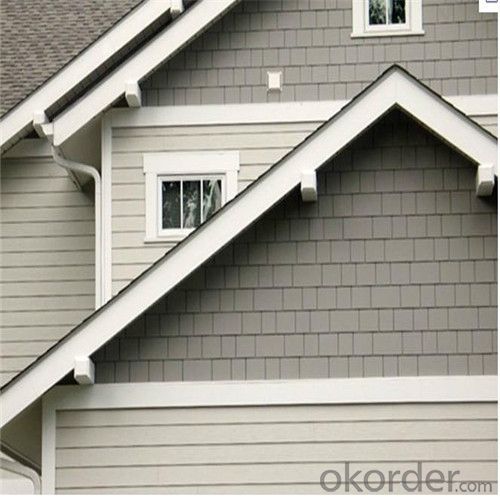

Sanle fiber cement board is made of high-grade cement and modified material, reinforced by natural fiber. Being processed by high pressure and high temperature advanced technologies, Sanle fiber cement board is a new building material with excellent performances.

Features

Fire Proof & Insulation

Class A non-inflammability, no toxic gas, low in perveance, good electric insulation material

Waterproof and Moisture Proof

In semi-outdoor area and under high temperature condition, performance of Sanle boards is stable and will not bend or deform.

Thermal Insulation and Sound Insulation

Low thermal conductivity, good heat insulation, high in density, sound proof

Light weight & High strength

Pressured by 5000-ton hydraulic machine, it is high in strength and light in weight. It is not easy to deform and bend, and good for flooring and roofing.

Easy installation

The installation of boards is dry operation, which is faster. It can be processed with ordinary wood working tool. The board is easy to be processed.

Economical and Good looking

The boards are light in weight. Together with the use of keels, they can save cost of construction and decoration. The painting is uniform, and the surface is smooth, making the exterior of buildings good-looking and attractive.

Safe and Harmless

Test result of Sanle boards is better than national radiation protection standards of building materials. The radiation from Sanle boards is equal to that from the lawn 20 meters away from the building. The lifespan of Sanle boards is very long, and they are resistant to acid and alkali, moisture and insects. The toughness and strength remains the same when time passes by. So they can be used for a long time.

Easy to install and easy to replace

Sanle boards can be drilled, cut, engraved, nailed, painted and covered by tiles or sticker when necessary..

Product parameters

Item | Unit | Requirement | ||||

Medium density | High density | |||||

Density | g/cm3 | 1.2<D≤1.5 | 1.5<D≤2.0 | |||

Water absorption | % | ≤30 | ≤25 | |||

Non-combustibility | GB 8624-2006, grade A | |||||

wet expansion | % | ≤0.25 | ||||

Beding strength | dry | MPA | Strength grade class III | 20 | Strength grade class IV | 24 |

Saturation with water | 12 | 14 | ||||

Applications

Exterior side boards, indoor partition walls, sound-proof ceiling, decoration boards, complex walls, outdoor billboards, division boards and floor boards

- Q: I am trying to anchor a woody climbing wall to a cinder block garage wall and have settled on anchoring boards into the cinder blocks then building from there. so anything anchored there would be sharing a load of me-200 lbs, the plywood base and frame - 50lbs. plus any force generated by my jumping around on it.

- Secure the wall to the floor of the garage with something like Simpson Concrete bolts - they work like Tap-Cons, but are larger and have a greater shear strength. To avoid having the garage wall, roof, and the climbing wall collapse on top of you (that's not even good avalanche practice), anchor the top to the top plate of the garage wall. It should be anchored into a bond-beam at the top of the wall with 1/2 diameter bolts. You could also hang the wall out a little further, and secure the top to several ceiling joists or roof rafters with framing anchors. Just do not attach the climbing surface directly to the block wall; either you will pull the anchors out, or push the wall over. Look at the Simpson-Strong Tie website for bolts and framing anchors. [You must have a pretty tall garage.]

- Q: My fear is that I will trap moisture where it shouldn't be. Is there such a thing as overkill?

- No problem. i dont call it overkill. I would rather do it know than wish i had.

- Q: Cement board can not wet paste

- Cement board is to wet paste.

- Q: I can ollie on the grass fine.I can ollie high and easy.But when i do it on cement i ollie high but when i pop it my right foot that on the tail slips off.So why does it do that.Can you tell me what going wrong.Help me.My foot always comes off :(

- it relatively is reason think ofyou've have been given so used to doing it on carpet. i does not recommend all and sundry studying tricks table certain on carpet. basically save working in the direction of it. you will could relearn it on cement.

- Q: I want to put a small addition to the side of my concrete bungalow. it will be shed with lean to roof I want to construct this without having to put columns/post on the side of the house what I want to do is attach like a piece of 2x4 or 1x4 to the wall horizontally and have my rafter attached to it. the excisting concrete wall is made of 6 inch thick cinder blocksplease help

- If it were me, I'd attach the board to the cinder block wall with tapcon screws and then use joist hangers for the roof beams. I'd use at least a 2x4... I'd probably go with something bigger, but I also tend to over-build. :)

- Q: There is a problem like your team to ask the partition wall have what form in addition to light steel keel gypsum board there are no other

- Partition classification 1, by the form: single glass partition double glass cut off 2, according to the material: vertical plate cut off metal cut off 3, according to use: office partition bathroom glass partition partition living room cut off the windows cut off the hotel partition 4, by function: furniture partition screen partition door cut off the curtain 5, according to the shape: high cut off the low cut off 6, by nature: fixed partition, activities cut off

- Q: I have a bare concrete/cement floor. After I installed Travertine on one section, it is almost 1/2 inch above the floor. Now, I want to continue to install the other section of the floor with laminate wood, but the floor is too low compared to the travertine floor. The question are: Can I put down a particle board over the concrete/cement floor, then a foam pad (moisture barrier), then laminate wood?Will the particle board absorb water then swell up?Or do I need to put down the moisture barrier foam first, then particle, then laminate wood?If I am not using the particle board, the laminate wood floor will be about 1/8 lower than the travertine floor. is it ok?

- Do NOT use particle board. There is no reason, as the laminate can be laid over the concrete with the proper padding. The particle board may swell and cause you issues down the road. Check the instructions on the flooring. Some require a plastic vapor barrier under them, while others only need the padding. 1/8 is not a big deal. The transition strip will bridge the difference. Be sure to check for peaks and valleys in the concrete, and fill in low spots. This will prevent the tongues on the planks from snapping off, leaving gaps in the floor. Allow the laminate to acclimate to the basement for a week or so before installing. Hope this helps. EDIT: You don't need anything under the flooring except vapor barrier or padding. They are designed to be able to be installed on a concrete base. Good luck.

- Q: What is a cement board?

- Cement board of his material is made of cement can basically say that no advantage is not afraid of water equipment can do with the best home Do not fool yourself that thing is generally used in the kitchen bathroom package with water column with the above can be attached to the wall, but can not take long and wall The connection will appear where the cracks will be very ugly if the column would like to stick that small red brick and then tiling

- Q: I have installed cement board ceiling & after painting i found cracks in joints of board.How can i rectify it?

- dude you messed up cement board for the ceiling take it down and use sheetrock

Send your message to us

Asbestos Free Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords