1 Inch Thick Aluminum Sheets - Five Bar Treadplate Aluminium Panel AA1xxx for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

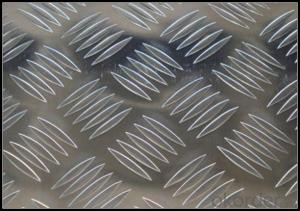

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

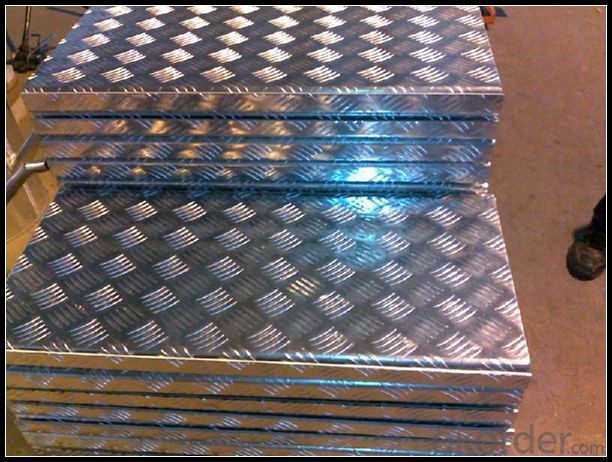

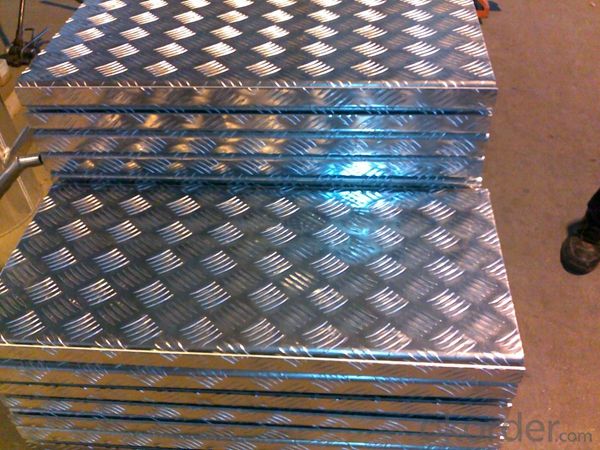

5. Image of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

6. Package and shipping of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum sheets tested for quality and compliance with industry standards?

- Aluminum sheets are tested for quality and compliance with industry standards through a comprehensive set of tests and inspections. These tests ensure that the aluminum sheets meet the required specifications and performance criteria. One of the commonly used tests is the visual inspection, where the sheets are examined for any surface defects such as scratches, dents, or cracks. This is crucial to ensure a smooth and flawless appearance. Further, dimensional checks are performed to verify the thickness, width, and length of the sheets. Precise measurements are necessary to meet the specific requirements of the intended application. To assess the mechanical properties, various tests are conducted. Tensile strength tests evaluate the maximum load the aluminum sheet can withstand before breaking. This helps determine the sheet's structural integrity and its ability to withstand external forces. Similarly, hardness tests measure the sheet's resistance to indentation or penetration, providing insights into its durability and resistance to wear. Chemical composition analysis is also conducted to ensure that the aluminum sheets contain the necessary alloying elements within the specified limits. This analysis helps confirm that the material composition aligns with industry standards, as different alloy compositions can affect the sheets' mechanical properties and suitability for various applications. Surface integrity is evaluated through corrosion resistance tests, which assess the sheet's ability to withstand environmental factors such as moisture, chemicals, and temperature variations. This is particularly important for applications where aluminum sheets are exposed to corrosive substances or harsh environments. In addition to these tests, aluminum sheets may undergo non-destructive testing techniques such as ultrasonic testing or eddy current testing. These methods help identify internal defects or irregularities that may not be visible through visual inspection alone. Overall, a combination of visual inspections, dimensional checks, mechanical tests, chemical composition analysis, and surface integrity evaluations are employed to ensure that aluminum sheets meet the quality standards and compliance requirements set by the industry. These rigorous testing procedures guarantee that the sheets are fit for their intended purpose and meet the expectations of customers.

- Q: What is made when Aluminium and Hydrochloric Acid reacts? It makes a dense white smoke with a metallic odour in the gas. Could it be dissolved amounts of Aluminium Chloride or small amounts of unreacted Aluminium in the gas? Or could be that the Chlorine (in equilibrium with HCl and HClO) made chlorates and perchlorates of aluminium that give off odours?Don't tell me the gas isn't supposed to have an odour. I know what diatomic Hydrogen smells like. Nothing. That's the way it should be. But unfortunately, that's not the way it is.

- i might call the plumber immediately. curiously there's a hollow interior the piping someplace, and the sulfuric acid would desire to have eaten by in spite of advance into clogging that hollow. I doubt that it will supply up leaking via itself, to no longer point out that acid is in all risk leaking into your kitchen in the present day.

- Q: Can the aluminum sheets be used for manufacturing medical equipment?

- Medical equipment can be manufactured using aluminum sheets, as they possess several properties that make them appropriate for this purpose. Aluminum is widely utilized in various industries, including healthcare, due to its versatility. To begin with, aluminum is both lightweight and durable, which is advantageous for the production of portable medical devices. This characteristic facilitates the handling and transportation of equipment, particularly for healthcare professionals who may need to move them frequently. Additionally, aluminum exhibits exceptional resistance to corrosion, rendering it suitable for medical applications where cleanliness and hygiene are paramount. It can endure disinfection processes without suffering any deterioration, thus ensuring the longevity of the equipment. Moreover, aluminum can be easily sterilized, which is crucial for medical equipment. It can withstand high-temperature sterilization methods, such as autoclaving, without experiencing any detrimental effects on its structural integrity. Furthermore, aluminum possesses excellent heat and electricity conduction properties. These attributes are beneficial for medical equipment that requires efficient heat dissipation or electrical conductivity, such as surgical instruments or diagnostic tools. Furthermore, aluminum is non-toxic, making it safe for medical use. It does not release harmful substances, guaranteeing the absence of health risks to both patients and healthcare professionals. In conclusion, aluminum sheets are indeed suitable for the manufacturing of medical equipment due to their lightweight nature, durability, corrosion resistance, sterilization capabilities, thermal and electrical conductivity, as well as their non-toxicity. These properties make aluminum an appropriate choice for various medical applications, thereby contributing to the advancement of healthcare technology.

- Q: Is the value of specific heat capacity of aluminium higher or lower than the standard value? Why?

- RE: Specific heat capacity of aluminium...? Is the value of specific heat capacity of aluminium higher or lower than the standard value? Why?

- Q: Can aluminum sheets be laminated?

- Yes, aluminum sheets can be laminated. Lamination is a process of bonding multiple layers together to create a composite material with enhanced properties. In the case of aluminum sheets, they can be laminated with other materials such as plastics, adhesives, or even other metals. This process can improve the strength, durability, and thermal or electrical conductivity of the aluminum sheets. Laminated aluminum sheets are commonly used in various industries, including construction, automotive, aerospace, and packaging, where the combination of different materials provides the desired characteristics for specific applications.

- Q: Could induction heating fuenace be packaged with aluminum foil as insulation material?

- It’s useless. Aluminum foil will generate eddy and emit heat after medium induction, which will reduce the thermal efficiency of medium frequency. Now I provide a method for reference only. Induction coil will be water cooling and is packaged by thermal cement and other materials. Use asbestos sheet and other materials to transform the both ends of induction heating coil as baffle which is mobile and convenient for load and unload. When steel tube is heated in the induction coil, you can put down the baffle to prevent large loss of heat, shorten heat time and improve heat efficiency. When the seamless steel tube is heated into setting temperature, you can open the baffle to conduct expanding process, and you don’t need to think about the thermorytic problem of steel tube in the expanding process. It’s important to shorten the time of expanding process. Baffle is used for heat retaining of medium frequency heating and extrusion forming in our factory. The method above for reference only.

- Q: Can aluminum sheets be used for battery enclosures?

- Yes, aluminum sheets can be used for battery enclosures. Aluminum is a widely used material for battery enclosures due to its excellent properties. It is lightweight, corrosion-resistant, and has good conductivity. These characteristics make it suitable for protecting batteries and ensuring their optimal performance. Aluminum's high strength-to-weight ratio also allows for the construction of sturdy yet lightweight enclosures, making it an ideal choice for various battery applications. Additionally, aluminum is easily recyclable, making it an environmentally friendly option. Overall, aluminum sheets are a viable and commonly used material for battery enclosures.

- Q: Are aluminum sheets suitable for aerospace structural components?

- Aerospace structural components can indeed be made from aluminum sheets. Aluminum is a material that is both lightweight and durable, and it has been used extensively in the aerospace industry for many years. Its exceptional strength-to-weight ratio makes it highly desirable for a range of applications in aircraft manufacturing. Aluminum sheets provide numerous advantages for aerospace structural components. Firstly, their lightweight nature helps to reduce the overall weight of the aircraft. This is crucial for improving fuel efficiency, increasing payload capacity, and enhancing overall performance. Additionally, the lightweight quality of aluminum sheets makes them easier to handle and assemble during the manufacturing process. Secondly, aluminum exhibits excellent resistance to corrosion. This is particularly important for aerospace applications, as the components are exposed to various environmental conditions, such as high humidity, extreme temperatures, and exposure to chemicals. The corrosion resistance of aluminum ensures that the structural components remain durable and long-lasting, reducing the need for frequent maintenance and replacement. Furthermore, aluminum is a highly malleable material, allowing for easy shaping and forming into complex structures. It can be bent, cut, and fabricated with ease to meet specific design requirements, making it versatile for a variety of aerospace applications. The ability to form intricate shapes with aluminum sheets enables engineers to design efficient and streamlined structures, optimizing aerodynamics and minimizing drag. Another advantage of aluminum sheets is their excellent thermal conductivity. This property enables efficient heat dissipation, which is crucial in aerospace applications where components may be exposed to high temperatures generated during flight or engine operation. The thermal conductivity of aluminum helps to prevent overheating and ensures the structural integrity of the components. In conclusion, the lightweight, corrosion resistance, malleability, and thermal conductivity properties of aluminum sheets make them highly suitable for aerospace structural components. These characteristics contribute to the overall performance, efficiency, and safety of aircraft, making aluminum an ideal material for various applications in the aerospace industry.

- Q: after putting aluminum sheet into the area between magnet and iron products, could magnet attract iron again?

- magnet can attract iron if the aluminum sheet isn't too thick. Because aluminum can't cut off magnetic line of force, unless aluminum sheet's thickness surpass the range of magnetic attraction.

- Q: Is it possible to utilize aluminum sheets for the construction of outdoor advertising billboards?

- <p>Yes, aluminum sheets are commonly used for outdoor advertising billboards due to their durability, lightweight, and resistance to weather conditions. They are easy to install, maintain, and can be printed with high-quality graphics. Additionally, aluminum's corrosion resistance makes it a sustainable choice for long-term outdoor use.</p>

Send your message to us

1 Inch Thick Aluminum Sheets - Five Bar Treadplate Aluminium Panel AA1xxx for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords