1.8mm Brushed Coated Aluminium Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

2.Our advantage

Our quality best, service best, price better!

3.Specification and application

Alunimiun Sheet

ALLOY: AA1*** (AA1050,AA1060,AA1070,AA1100 etc.)

AA3*** (AA3003,AA3004,AA3005,AA3105 etc.)

AA5*** (AA5052,AA5083,AA5754 etc)

AA8*** (AA8011,AA8006 etc)

TEMPER: H14,H16,H18,H22,H24,H26,H32,O/F

THICKNESS: 0.2mm-100mm

WIDTH: 30mm-1700mm

STANDARD: GB/T 3880-2006

Special specification is available on customer's requirement

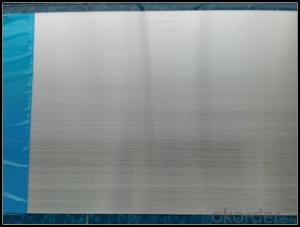

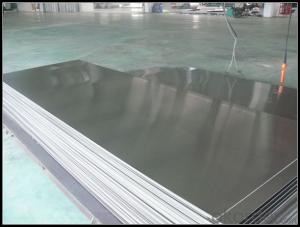

SURFACE QUALITY: GOOD APPEARANCE WITH NO-CRACK AND WELL-DISTRIBUTE GRAIN.

BUILD UP: TIGHT SLIT EDGES FREE FROM CRACKS, LAYER TO LAYER SHIFT NOT MORE THAN 2MM.

PROFILE: -0/+1%

FLATNESS: MILL FLATNESS COIL HAVING EDGE WAVINESS RATHER THAN CENTER BUCKLES SHALL BE ACCEPTABLE.

ROLLING PERFORMANCE: RE-ROLLABLE TO THE FINAL DESIRES GAUGES

4.Pictures

5.FAQ

1)Can we supply samples?

Yes, we can!

2)What can you do if you have other quastions?

You can contact us freely at any time!

Construction is one of the three major markets of aluminum sheets, about 20% of the world's total output of aluminum for the construction industry, a number of aluminum constructions in industrial countries, the amount of aluminum accounts for more than 30% of its total production. In recent years, aluminum construction products constantly updated, color aluminum, aluminum composite, composite door window frames, aluminum templates novel application of building products has also increased. China has been used in industrial and civil construction in aluminum alloy roof, walls, doors and windows, and gradually extended to external decoration, construction template, etc., we have achieved good results.

The most important feature of aluminum is light weight and weighs only 1/3 of steel, but the intensity (the ratio of ultimate strength and specific gravity) can reach or exceed the structural steel. Secondly, aluminum easily processed into various shapes, can adapt to a variety of process connections, thus providing favorable conditions for the construction of the structure using the most economic justice sectional form. Therefore, the use of aluminum not only can greatly reduce the weight of the building, saving construction materials, but also reduce transport member, installation work, and speed up the construction progress. This earthquake zone and inaccessible mountainous and remote areas, its economic effect is more obvious. Aluminum luster appearance, corrosion resistance, high reflectance of light and heat, sound absorption performance is good, get a variety of colors by chemical and electrochemical methods. Therefore, aluminum is widely used in industrial and civil construction of the roof, walls, doors, windows, frame, both interior and exterior panels, ceiling, ceiling, handrails, indoor furniture, container and store templates used in construction.

According to their mode of production, aluminum sheet can divided into forged aluminum and wrought aluminum alloy two categories. On the general, deformation of aluminum alloy for rolled sheet, foil, strip, extruded rods, tubes or profiles of complex shape are used in building. Deformation of aluminum alloy their function, for different purposes, divided into rust-proof aluminum, hard aluminum, super-hard aluminum and special aluminum. Buildings generally use rust-proof aluminum and aluminum alloy wrought aluminum.

- Q: What are the rules and standards that govern the use of aluminum sheets in construction projects?

- <p>Yes, there are regulations regarding the use of aluminum sheets in construction. These regulations vary by country and region but generally cover aspects such as material standards, safety, and environmental impact. For instance, in the United States, the American Society for Testing and Materials (ASTM) provides standards for aluminum sheet materials. Building codes like the International Building Code (IBC) also specify requirements for the use of aluminum in construction. These regulations ensure that aluminum sheets meet certain strength, durability, and performance criteria. Compliance with these regulations is crucial for safety, structural integrity, and to obtain necessary permits and approvals for construction projects.</p>

- Q: Can aluminum sheets be used for bus bodies?

- Yes, aluminum sheets can be used for bus bodies. Aluminum is a lightweight yet durable material that offers excellent corrosion resistance, making it a popular choice for constructing bus bodies. Its high strength-to-weight ratio allows for improved fuel efficiency and increased payload capacity. Additionally, aluminum can be easily molded and shaped, enabling manufacturers to design buses with unique and modern aesthetics.

- Q: A dry aluminium foil paper can be bring out from oven with no burn on finger but if foil has some moisture it will result in burn why?

- The Principle behinf Microwave oven heating is that it heats up only water molecules, that is, the frequency of microwaves can only heat up water molecules ( make them oscillate and hence heat up). So if there is any trace of water or moisture on any object that you keep in the oven, it will heat up and that heat will be conducted throughout the object. Hence the foil with moisture is effectively heated whereas dry foil have no water moecule and hence will not be heated up. Hope it helps:) Can explain better if you tell me which level you are studying:)

- Q: How much should I be charged to have aluminum siding installed? I have a two floor single family home which is detached. I also would want new gutters installed and soffets (i think that is what they are called). One company estimated 12k and another said 10K. This would entail just putting the siding over the original siding. Any answers are appreciated.

- You have no say in the matter. The insurance company is paying the contractor to remove and dispose of the old siding. They don't care if the contractor makes a few hundred bucks selling the siding as scrap and neither should you.

- Q: Are 101 aluminum sheets suitable for cryo-treating applications?

- Yes, 101 aluminum sheets are suitable for cryo-treating applications. Cryo-treating involves subjecting materials to extremely low temperatures to improve their strength, durability, and wear resistance. 101 aluminum is a commercially pure alloy with excellent corrosion resistance and good mechanical properties. It can withstand cryogenic temperatures without significant loss of strength or other negative effects. Therefore, 101 aluminum sheets can be successfully used in cryo-treating applications, providing the desired benefits and performance enhancements.

- Q: Can aluminum sheets be used for elevator panels?

- Indeed, elevator panels can be made using aluminum sheets. Aluminum, renowned for its versatility and durability, finds extensive utility in construction and architectural undertakings, such as crafting elevator interiors. It possesses various merits, including its lightweight nature, resistance to corrosion, and effortless maintenance. Aluminum panels can be tailored to meet the precise design prerequisites of elevator interiors, and their aesthetic appeal and durability can be amplified by applying diverse surface treatments or coatings. Moreover, aluminum emerges as an environmentally-conscious choice for elevator panels due to its sustainability, as it can be readily recycled.

- Q: Which kind of glue can bond hard shell plastic and iron sheet or aluminum sheet?

- You can use 502, Alteco and other instant glue to bond plastic and metal, chloroprene rubber adhesive or glass cement are also ok.

- Q: Status of aluminum sheet F

- The condition code only indicates that the product is in the natural aging stageT heat treatment status (different from F, O, H state) applicable to heat treatment, after (or without) hardening work to achieve stable products,.T code must be followed by one or more Arabia digital

- Q: How do you calculate the price and weight of aluminum sheet?

- The material of aluminum plate is divided into many grades100110021003 and so on, each price is not the sameAccording to the smoothness after processing, smoothness and so on, there are larger come and goI remember last year's 2.5 thick 1001 aluminum plate cost price is about 230 square meters

- Q: Calculate the mass in grams of Iodine (I2) that will react completely with 20.4 g of aluminum to form aluminum oxide (AlL3)

- Aluminium oxide? Shouldn't it be Aluminium iodide? 1. Form a balanced equation 3I2 + 4Al - 2Al2I3 2. Number of moles of Al 20.4/(Mr of Al) = 20.4/27 = 0.7555mol 3. Number of moles of I2 0.7555/4 x 3 = 0.5666mol 4. Mass of I2 required = 0.5666 x Mr of I2 = 0.5666 x (127x2) Ans: 143.9164g

Send your message to us

1.8mm Brushed Coated Aluminium Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords