Embossed Aluminum Corrugated Plastic Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Embossed Aluminum Sheets

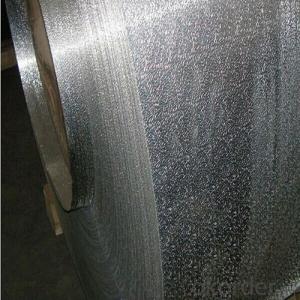

Embossed Aluminum Sheets has great ductility, heat conductivity, anti-corrosion and moisture resistance properties which are very useful in the field of construction.

Embossed Aluminum Sheets is widely used for decorative purpose in construction, packing and appiance. It is also very commonly used for anti-slippery purpose in vehicles and public places.

2.Main Features of Embossed Aluminum Sheets

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

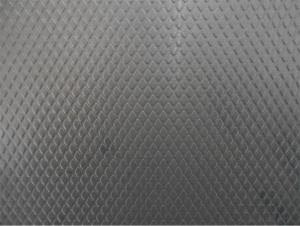

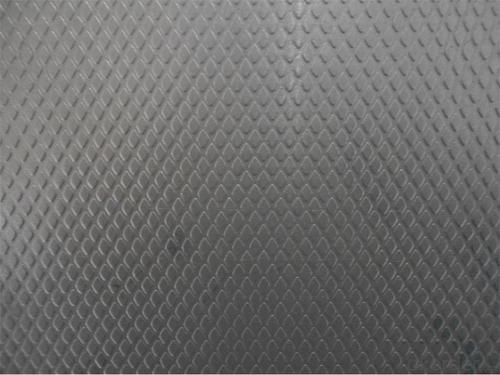

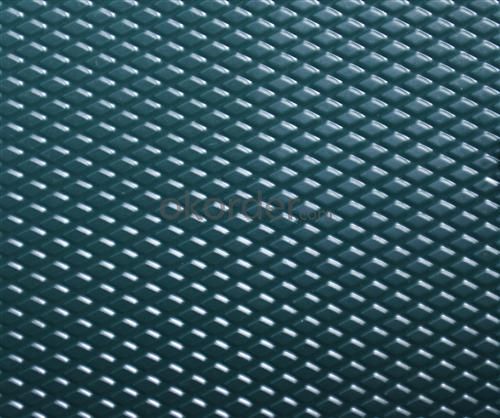

3.Embossed Aluminum Sheets Images

4.Embossed Aluminum Sheets Specification

| Alloy | AA1xxx,AA3xxx,AA5xxx |

| Temper | H14,H18,H24,H26,H32 |

| Thickness | 0.2mm--20mm |

| Width | 10mm--1500mm |

| Embossed Patterns | Diamond,Stucco,Bars etc. |

| Standard | GB/T 3880-2006 |

5. FAQ of Embossed Aluminum Sheets

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Embossed Aluminum Sheets products.

B.When will you deliver the products?

Embossed Aluminum Sheets will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Can someone please explained what aluminum reacts slowly with dilute acided?Thank you!

- Firstly, dilute acids are weaker than concentrated acids. This slows the rate of reaction. Secondly, Aluminium is less reactive than the Group 1 and Group 2 metals, which slows the rate of reaction. It is less reactive because it has to form 3+ ions which is more draining than forming 1+ or 2+ ions. Thirdly, Aluminium oxidises well in air but, unlike rust, this oxide sticks to the pure aluminium, forming a protective layer.

- Q: Can aluminum sheets be used for heat sinks?

- Yes, aluminum sheets can be used for heat sinks. Aluminum is a popular material for heat sinks due to its high thermal conductivity, lightweight nature, and affordability. It efficiently transfers heat away from electronic components or devices, helping to dissipate and regulate their temperature effectively.

- Q: Does aluminum foil keep food warm or cool, or is it just a convenient material to cover food with?

- It can insulate food, depending on how thick it is or how many layers you use. Aluminum foil is multi-functional: 1) Acts as a lid if you don't have one for any pot or pan. 2) As you mentioned: its a convenient material to cover food. 3) Can be used for lining the drip tray on your stove top for easy clean up. 4) Can be used as a non-stick liner for sheet pans when baking cookies or brownies. 5) Fish can be wrapped in aluminium foil and then steamed in the oven.

- Q: Can aluminum sheets be used for chemical storage containers?

- Certainly, chemical storage containers can utilize aluminum sheets. Renowned for its exceptional resistance to corrosion, aluminum proves itself as a suitable medium for accommodating a diverse array of chemicals. Its lightweight nature, durability, and lack of reactivity with most substances further enhance its appeal for chemical storage purposes, granting it popularity in this field. Moreover, aluminum boasts the ability to be easily shaped and fashioned into an assortment of dimensions and configurations, affording the luxury of customized container designs. Nonetheless, it is crucial to take into account the specific chemical being stored and seek guidance from experts to ensure compatibility and guarantee safety.

- Q: What are the standard thicknesses for aluminum sheets utilized in construction?

- <p>Yes, there are standards for the thickness of aluminum sheets used in construction. These standards vary by country and application. In the United States, the Aluminum Association sets standards, such as AA 3003-H14, which is commonly used in construction for thicknesses ranging from 0.020 to 0.250 inches. In Europe, EN 485-2 covers the specifications for aluminum sheet thicknesses. Thicknesses can range from 0.4mm to 6.0mm, depending on the specific requirements of the construction project. It's important to consult the relevant standards for the region and application to ensure compliance and proper material selection.</p>

- Q: Are the aluminum sheets suitable for signage or advertising purposes?

- Yes, aluminum sheets are highly suitable for signage or advertising purposes. Aluminum is a versatile and durable material that is resistant to rust, corrosion, and weathering, making it ideal for outdoor use. It is lightweight, allowing for easy installation and transport, and its smooth surface provides a professional and sleek appearance. Aluminum sheets can be easily cut, shaped, and engraved, allowing for customization and creativity in designing eye-catching signs and advertisements. Additionally, aluminum sheets can be printed on directly or laminated with vinyl, allowing for vibrant and long-lasting graphics. Overall, the properties of aluminum make it an excellent choice for signage and advertising purposes.

- Q: My aluminum storm windows are wasting energy in my home, however, the $7000 estimate to replace them is beyond (well beyond) my comfort zone.I know aluminum is a great conductor of hot and cold. I was considering cleaning the frames, and then coating them with a brush on clear or possibly white liquid rubber to reduce the conductivity. Any idea as to how much benefit I'll realize? Is flammability going to be an issue?I need some solid answers please. Trolls go get your two points elsewhere.Thanks.Your help is much appreciated.

- There are rubberized automotive undercarriage coatings that are designed to adhere to all metals, including aluminum. That would solve the problem of finding something that can stick to the frames, but I honestly don't know if it would help with the heating issue. I also believe they only come in black, I'm not sure if there's a white but it could be painted, Chassis Saver by Magnet is one I believe, the other is a Por 15 product. I'd like to know if it works though, I've got similar problems in my house.

- Q: Aren't metals in general (and aluminium in particular) excellent heat conductors?

- Yes aluminium is a good heat conductor, which is why it is used as a heatsink to dissipate heat from electronic components like the CPU in you laptop. The idea of the aluminium stand for your laptop is to raise it up from the desktop surface, allowing air to pass between the gap and extract the heat from the aluminium stand as your laptop heats up with use.

- Q: This question asks for the various types of adhesives that can be used for bonding aluminum profiles when constructing exterior cladding.

- <p>For bonding aluminum profiles in exterior cladding, several types of adhesives are commonly used. These include: 1. Structural adhesives, which provide strong and durable bonds suitable for load-bearing applications. 2. Silicone sealants, known for their flexibility and resistance to weathering, making them ideal for sealing gaps and joints. 3. Acrylic adhesives, which offer good adhesion and flexibility, and are often used for bonding aluminum to other materials. 4. Epoxy adhesives, known for their high strength and resistance to chemicals, making them suitable for demanding environments. 5. Polyurethane adhesives, which provide strong bonds and excellent resistance to moisture and temperature changes. The choice of adhesive depends on factors such as the specific application, environmental conditions, and required performance characteristics.</p>

- Q: There are about 200 holes on the aluminum plate to be machined. There are 100 M12 thread holes, and the rest are 15MM through holes. The tolerance is +0.02. Seeking detailed processing technology, is the first hole or first processing plane, how to control the amount of deformation of the plate, if the milling process can not guarantee flatness, on the grinder, then the 2 surfaces to stay 2MM margin? Are there any 15MM through holes that can be used to maintain tolerances, or do they need to be boring?. Great God advice, the best detail. Aluminum so much done before, no experience, if it does it scrapped.

- The thickness of 2 to 1. fly in place stress to ensure the flatness of the fitter leveling 0.13 more than the Xicheng pay attention to the protection of the appearance of 4 to ensure the flatness of the fabricated fitter. - this thing must not need to be so high, 100 M12 threaded holes, you still press the map to ensure that ah? Such a large plate deformation, 2 millimeters below the hole can be pressed to do

Send your message to us

Embossed Aluminum Corrugated Plastic Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords