Corrugated Aluminum Sheets Price - Manufacturer Four Colors and Spot Color HD Metal Print

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

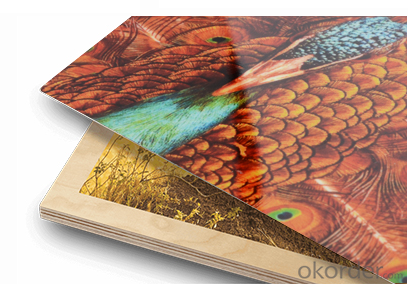

These Aluminum Panels can provide for many sizes and different color. It can suitable in many occasion, like company logo screen, show backdrop, home use, some gift use etc. We can also provide the heat press machine for transferring.

Features:

1. Extremely durable scratch resistant surface that is waterproof and can be cleaned easily with a damp cloth.

2. Eco-friendly & Terrific as a decoration.

3. Longest lasting photo medium in the current market.

4. The high definition, vibrant colors coupled with superior fade, moisture, stain & scratch resistant properties.

5. The image is infused into the coating to provide permanent protection and durability.

6. Excellent choice for commercial, fine art, and home decoration applications.

Making Process:

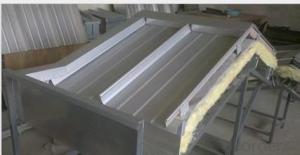

1. Get images from digital camera, memory card or scanner.

2. Print image with heat transfer paper and sublimation ink.

3. Lay down a teflon sheet and your panel, and another CLEAN teflon sheet on top, pre-press for 60 sec., 180℃, 0.3Mpa.

4. 60 seconds later. Wait the panel to cool.

5. Tape the transfer to the face of the substrate with heat resistent tape running parallel to the edge of the substrate.

6. Lay substrate face up, transfer on top on a piece of telfon sheet on lower platen.

7. Cover with one layer of fabric, preferably 100% polyester or poly-silk, to distribute pressure and reduce stress on the coating.

8. Press for the prescribed time is 130sec., temperature is 180℃ and pressure is 0.3Mpa.

9. When finished, remove the fabric and gently peel the taped transfer off the substrate without allowing it to slide or move.

10. Let the substrate to cool. Do not handle it until cool to reduce the chances of damaging the coating on the edges.

11. Enjoy your personal designed aluminum board!

| Item# | Description | Size(in) | Size(mm) | Qty |

42030037 | Photo panel | 2" x 3" | 50.8x76.2 | 50 |

42030036 | Square photo panel | 4" x 4" | 101.6x101.6 | 10 |

42030012 | Photo panel | 4" x 6" | 101.6x152.4 | 10 |

42030032 | Square photo panel | 5" x 5" | 127x127 | 10 |

42030005 | Square photo panel | 6" x 6" | 152.4x152.4 | 10 |

42030004 | photo panel | 5" x 7" | 127x177.8 | 10 |

42030033 | Photo panel | 5" x 11" | 127x279.4 | 10 |

42030009 | Square photo panel | 8" x 8" | 203.2x203.2 | 10 |

42030013 | Photo panel | 5" x 10" | 127x254 | 10 |

42030038 | Photo panel | 8" x 10" | 203.2x254 | 10 |

42030034 | Photo panel | 5" x 17" | 127x431.8 | 10 |

42030024 | Photo panel | 8" x 12" | 203.2x304.8 | 10 |

42030010 | Square photo panel | 10" x 10" | 254x254 | 10 |

42030035 | Square photo panel | 11" x 11" | 279.4x279.4 | 10 |

42030003 | Square photo panel | 11.75"x 11.75" | 298.4x298.4 | 10 |

42030014 | Square photo panel | 12" x 12" | 304.8x304.8 | 10 |

42030031 | Photo panel | 11" x 17" | 279.4x431.8 | 10 |

42030006 | Photo panel | 9" x 21" | 228.6x533.4 | 10 |

42030015 | Photo panel | 10" x 20" | 254x508 | 10 |

42030042 | Photo panel | 11" x 14" | 279.4x355.6 | 10 |

42030025 | Photo panel | 12" x 18" | 304.8x457.2 | 10 |

42030028 | Square photo panel | 15" x 15" | 381x381 | 10 |

42030011 | Photo panel | 14" x 18" | 355.6x457.2 | 10 |

42030016 | Square photo panel | 16" x 16" | 406.4x406.4 | 10 |

42030017 | Photo panel | 12" x 24" | 304.8x609.6 | 10 |

42030002 | Photo panel | 15 "x 18.75" | 381x476.2 | 10 |

42030001 | Photo panel | 16" x 20" | 406.4x508 | 10 |

42030023 | Photo panel | 16" x 24" | 406.4x609.6 | 10 |

42030029 | Photo panel | 10" x 30" | 254x762 | 10 |

42030018 | Square photo panel | 20" x 20" | 508x508 | 10 |

42030019 | Photo panel | 20" x 24" | 508x609.6 | 10 |

42030020 | Square photo panel | 24" x 24" | 609.6x609.6 | 10 |

42030007 | Photo panel | 24" x 26" | 609.6x660.4 | 10 |

42030043 | Photo panel | 24" x 36" | 609.6x914.4 | 10 |

42030008 | Photo panel | 20" x 30" | 508x762 | 10 |

42030021 | Photo panel | 24" x 30" | 609.6x762 | 10 |

42030026 | Photo panel | 16" x 32" | 406.4x812.8 | 10 |

42030027 | Photo panel | 18" x 36" | 457.2x914.4 | 10 |

42030030 | Square photo panel | 30" x 30" | 762x762 | 10 |

42030022 | Photo panel | 30" x 40" | 762x1016 | 10 |

42030039 | Photo panel | 32" x 40" | 812.8*1016 | 9 |

42030040 | Square photo panel | 36" x 36" | 914.4x914.4 | 6 |

42030041 | Square photo panel | 48" x 48" | 1219.2x1219.2 | 6 |

- Q: What is the typical cost-effectiveness of aluminum sheets compared to other materials?

- Aluminum sheets are generally considered to be cost-effective compared to other materials. This is primarily due to their abundance, lightweight nature, and recyclability, which reduces production costs. Additionally, aluminum sheets offer a high strength-to-weight ratio, corrosion resistance, and durability, making them a popular choice across various industries. However, specific cost-effectiveness may vary depending on factors such as market demand, sheet thickness, and finishing requirements.

- Q: Is it possible to use aluminum sheets as a material for interior wall decoration?

- <p>Yes, aluminum sheets can be used for interior wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications. Aluminum sheets are also easy to install and maintain, and they can be painted or finished in various ways to match different design styles. However, it's important to ensure proper installation and adherence to local building codes and regulations.</p>

- Q: Are aluminum sheets suitable for signage and advertising?

- Yes, aluminum sheets are suitable for signage and advertising. They are durable, weather-resistant, and can be easily customized with graphics and text. Additionally, their sleek and professional appearance makes them an excellent choice for promotional materials, outdoor signs, and indoor displays.

- Q: Describe the steps involved in the production of aluminum sheets.

- <p>The process of manufacturing aluminum sheets involves several key steps. Initially, raw materials, primarily bauxite, are mined and then processed to extract alumina (aluminum oxide). This alumina is then mixed with cryolite and fed into a reduction cell where it is subjected to a strong electric current, causing the aluminum to be reduced and extracted. The molten aluminum is then poured into molds to cool and solidify into ingots. These ingots are subsequently rolled into sheets in a hot or cold rolling process, where they are gradually reduced in thickness and width. The sheets are then annealed to improve their ductility and strength. Finally, they undergo various finishing processes such as cleaning, coating, or cutting to meet specific requirements before being packaged and shipped to customers.</p>

- Q: why can aluminum sheet after oxide film removal react quicker with hydrochloric acid?

- the reason is very simple, the original aluminum sheet has a layer of dense oxide film AI2O3, which has prevented the inner aluminum sheet from reacting with hydrochloric acid. but after oxide film removal, aluminum sheet will directly contact hydrochloric acid, generating H2.

- Q: Does aluminum resist fire or is it not susceptible to catching fire?

- <p>Aluminum sheets are not fireproof but have a high resistance to fire. They do not burn or support combustion like wood or paper. Aluminum has a melting point of around 660掳C (1220掳F), and it forms a protective oxide layer when heated, which prevents further oxidation and slows down the heating process. While it can get hot and deform under extreme heat, it won't catch fire or contribute to a fire's spread. However, it's important to note that aluminum can still conduct heat, so it's not completely immune to the effects of fire.</p>

- Q: Can aluminum sheet be used for chemical processing?

- Yes, aluminum sheet can be used for chemical processing. Aluminum is a versatile and corrosion-resistant material that is widely used in various industries including chemical processing. It is known for its excellent resistance to many chemicals, such as acids, alkalis, and salts. This makes it suitable for applications where exposure to corrosive substances is common. Additionally, aluminum is lightweight, durable, and has good thermal conductivity, making it an ideal choice for heat transfer and energy-efficient processes in chemical industries. However, it is important to consider the specific chemical environment and consult with experts to ensure the compatibility of aluminum with the particular chemicals and conditions involved in the process.

- Q: 1100 scope of application of aluminum plate

- 1100 aluminum plate is generally used in utensils, heat sink, caps, printing plates, building materials, heat exchanger components, but also can be used as deep stamping products. It is widely used in various fields ranging from cooking utensils to industrial equipment

- Q: For example, in hydrangeas, when aluminum reacts with the anthocyanins in the flower's petals, the hydrangeas turn blue, but what chemical reaction occurs?

- Two factors affect the color in Hydrangea macrophylla cultivars: soil acidity and the presence of aluminium in the soil. To obtain a blue hydrangea, aluminum must be present in the soil. The pH of the soil should be low (4 - 4.5). In alkaline soil aluminium is tied up. The plants are unable to absorb the existing aluminium and the flowers will not bloom blue. Also, when aluminium in the soil is used up the flower color will be red or pink again. If the soil is watered with aluminium salts aluminium is accumulated in the petals and the color turns blue. Only red and pink colored Hortensis are suitable for the breeding of blue flowers. They contain the dye component delphinidin. At the end of this site you find explanation and the formula: www.uni-regensburg.de/Fakultaeten...

- Q: In which autocomponents usage of aluminium is better or otherwise?

- Aluminium is lighter as well as stronger than CI. Thats the reason most of the Automobile manufacturers use Aluminium for car bodies while they use cast iron for the underframes and internal chassis....NMN

Send your message to us

Corrugated Aluminum Sheets Price - Manufacturer Four Colors and Spot Color HD Metal Print

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords