CORRIGATED SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

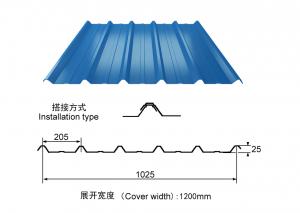

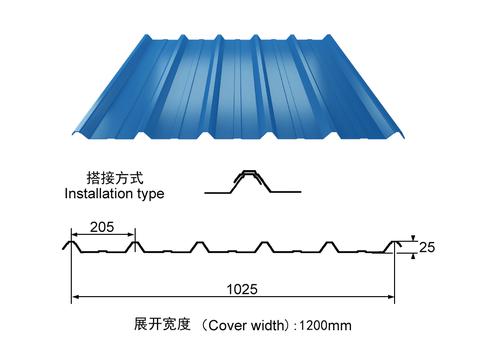

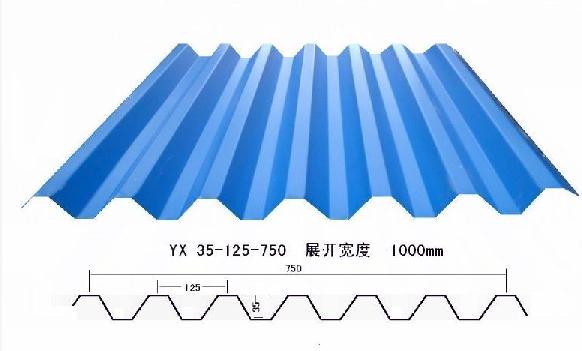

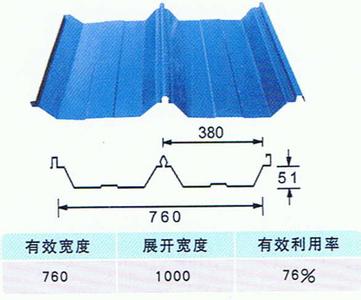

Product Name:corrugated steel roofing sheet

Effective Width:650mm to 1250mm

Thickness:0.13mm-0.8mm

Material PPGI/PPGL steel coil

Coating:Z30-Z275,AZ30-AZ180

Color:white,blue or any RAL colors

length:1m-11.8m according to the container

top color coating:12um-25um

Back color coating:7um-10um

HRB:50-95

Base plate:PRE-PAINTED ALUZINC STEEL COIL,PRE-PAINTED GALVANIZED STEEL COIL

- Q: Can the steel sheets be easily folded or creased?

- No, steel sheets cannot be easily folded or creased due to their strong and rigid nature.

- Q: What are the different types of surface patterns available for steel sheets?

- There are several different types of surface patterns available for steel sheets, including smooth, textured, embossed, diamond, and perforated patterns.

- Q: How do steel sheets perform in terms of impact resistance?

- Steel sheets are known for their exceptional impact resistance. Due to their high strength and rigidity, steel sheets are able to withstand significant impacts without deformation or failure, making them highly reliable and suitable for various applications where impact resistance is crucial.

- Q: Are the steel sheets resistant to warping or twisting?

- Yes, steel sheets are highly resistant to warping or twisting. Steel is known for its exceptional strength and rigidity, making it less susceptible to deformation under stress or pressure. The inherent properties of steel, such as its high tensile strength and low thermal expansion, contribute to its resistance to warping or twisting. Additionally, steel sheets are often manufactured with precise dimensions and uniform thickness, further enhancing their resistance to deformation. This makes steel sheets a reliable and durable choice for various applications that require stability and structural integrity.

- Q: Do steel sheets have any environmental benefits?

- Yes, steel sheets have several environmental benefits. Firstly, steel is a highly recyclable material, meaning that it can be reused multiple times without losing its quality. This significantly reduces the need for new steel production, which in turn reduces the extraction of raw materials and the energy consumption associated with manufacturing. Recycling steel also helps in reducing greenhouse gas emissions and conserving natural resources. Additionally, steel sheets are extremely durable and long-lasting. They have a high resistance to corrosion, which means they require minimal maintenance over their lifespan. This durability reduces the need for frequent replacements, thus reducing the demand for new steel production and the associated environmental impact. Moreover, steel sheets can contribute to energy efficiency in buildings. When used as roofing or cladding material, steel sheets can provide excellent insulation properties, helping to reduce heating and cooling energy requirements. This leads to lower energy consumption and, consequently, a reduced carbon footprint. Furthermore, steel sheets are fire-resistant, which enhances the safety of buildings and reduces the risk of fire-related accidents. This can have positive environmental impacts by minimizing the release of harmful emissions and pollutants resulting from fires. In conclusion, steel sheets offer various environmental benefits, such as recyclability, durability, energy efficiency, and fire resistance. These qualities contribute to a more sustainable and eco-friendly approach in construction and manufacturing industries.

- Q: Do the steel sheets have any specific certifications?

- Yes, the steel sheets have specific certifications.

- Q: Can steel sheets be used for outdoor sculptures?

- Yes, steel sheets can be used for outdoor sculptures. Steel is a durable and weather-resistant material that can withstand outdoor conditions, making it suitable for sculptural installations in outdoor environments. Its strength and versatility allow for various creative possibilities in sculpting outdoor artworks.

- Q: How do steel sheets perform in terms of dimensional stability?

- Steel sheets have excellent dimensional stability. This is because steel is a strong and rigid material that resists warping, bending, and expanding or contracting due to temperature changes. It maintains its shape and size, making it an ideal choice for applications that require precise and consistent dimensions.

- Q: How are steel sheets protected against rusting?

- Steel sheets are protected against rusting through a process called galvanization. This involves coating the steel sheets with a layer of zinc, which acts as a protective barrier against moisture and oxygen, preventing rust formation. Additionally, other methods such as painting or applying corrosion-resistant coatings can also be used to further enhance the protection against rusting.

- Q: How much is one meter for laser cutting steel plates?

- The above price is for low carbon steel. The price of stainless steel is lower than that of low carbon steel. Mainly nitrogen, a large amount.Of course, the specific price with the processing capacity of the size, the shape of the parts (compare all holes can not be completely by the meter, whether to count) freight, whether it is with material processing have a great relationship.

Send your message to us

CORRIGATED SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords