0.020 Aluminum Sheets - Aluminium Prepainted Coil with PVDF and Different Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Prepainted Coil with PVDF and Different Colors Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepainted Coil with PVDF and Different Colors:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

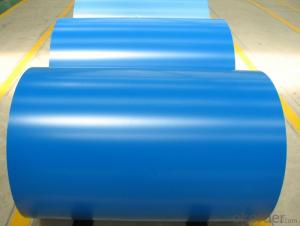

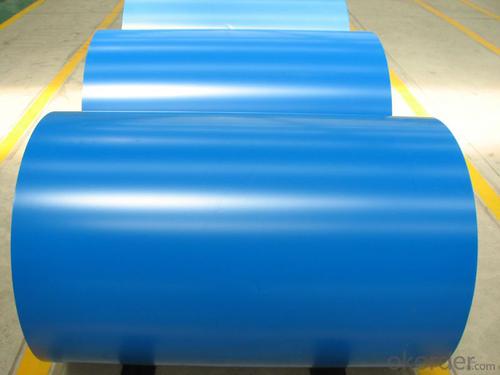

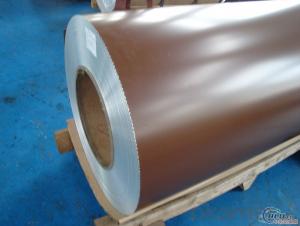

Images of the Aluminium Prepainted Coil with PVDF and Different Colors:

Aluminium Prepainted Coil with PVDF and Different Colors Coil Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: why is aluminium used instead of copper for high voltage electrical cables????

- Aluminum would only make sense in low current applications where cost and weight are important.

- Q: Can aluminum sheets be brushed or satin finished?

- Yes, aluminum sheets can be brushed or satin finished.

- Q: Can aluminum sheets be bent without breaking?

- Aluminum sheets possess the remarkable ability to endure bending without shattering. As a metal, aluminum boasts exceptional malleability and ductility, rendering it effortlessly moldable and pliable. This quality renders aluminum an optimal substance for a wide array of purposes, encompassing the production of aircraft, automobiles, and household articles. The pliability of aluminum sheets facilitates the crafting of intricate designs and intricate forms, establishing it as an exceptionally adaptable substance. It is, nonetheless, worth mentioning that the thickness and caliber of the aluminum sheet may impact its susceptibility to bending. Thicker sheets may necessitate increased force and specialized tools to achieve the desired curvature, whereas softer aluminum grades may yield to bending with greater ease.

- Q: Are 101 aluminum sheets suitable for conductive heat transfer applications?

- 101 aluminum sheets are not appropriate for applications involving conductive heat transfer. This specific aluminum alloy, known as 101 aluminum, is commercially pure and has a low electrical conductivity. Consequently, it is ineffective at efficiently conducting heat, rendering it unsuitable for situations requiring heat transfer. Instead, it is advisable to employ alloys with higher thermal conductivity, such as 6061 or 7075 aluminum, for conductive heat transfer applications. These alloys possess superior heat transfer properties and are commonly utilized in heat sinks, heat exchangers, and other scenarios demanding efficient heat transfer.

- Q: What are the different types of coatings available for aluminum sheets?

- There are several different types of coatings available for aluminum sheets, each offering unique properties and benefits. 1. Anodized Coating: Anodizing is a popular coating method that involves immersing the aluminum sheet in an electrolyte bath and passing an electric current through it. This process creates a durable and corrosion-resistant layer of oxide on the surface of the sheet. Anodized coatings can come in various colors and offer excellent abrasion resistance. 2. Powder Coating: Powder coating involves applying a dry powder to the aluminum sheet and then curing it under heat. This coating method provides a durable, uniform, and attractive finish. Powder coatings are available in a wide range of colors and textures and offer excellent resistance to chipping, scratching, and UV fading. 3. Paint Coating: Aluminum sheets can also be coated with liquid paint. This method provides versatility in terms of color choices and finishes. Paint coatings offer good resistance to weathering, impact, and chemicals, but they may not be as durable as anodized or powder coatings. 4. Cladding: Cladding is a process in which a layer of a different metal, such as stainless steel or copper, is bonded to the aluminum sheet surface. This provides added protection, improved aesthetic appeal, and can enhance the sheet's mechanical properties. 5. Laminating: Laminating involves bonding a protective layer, such as a film or sheet, onto the surface of the aluminum sheet. This coating method offers protection against abrasion, UV rays, and chemicals, and can also provide decorative finishes. 6. Organic Coating: Organic coatings, such as polyurethane or acrylic coatings, are applied to aluminum sheets to provide protection against corrosion, weathering, and chemical exposure. These coatings offer flexibility, good adhesion, and a wide range of color choices. Overall, the choice of coating for aluminum sheets depends on the specific requirements of the application, such as durability, corrosion resistance, aesthetic appeal, and cost-effectiveness.

- Q: What are the different grades of aluminum sheets?

- In the market, a variety of aluminum sheet grades can be found, each having its own unique properties and uses. Some commonly used grades are 3003, 5052, and 6061. Grade 3003, a non-heat treatable alloy, displays high resistance against corrosion. It finds its application in scenarios where corrosion resistance is crucial, such as packaging, cooking utensils, and chemical equipment. Grade 5052, also non-heat treatable, offers exceptional corrosion resistance along with strength and durability. This makes it suitable for marine applications, transportation equipment, and architectural purposes. Grade 6061, a heat treatable alloy, combines good corrosion resistance with high strength. It is extensively used in structural applications like aircraft components, automotive parts, and construction materials. In addition to these grades, there are specialized aluminum alloys like 2024, 7075, and 5083, catering to specific properties required in particular industries or applications. To ensure the right grade of aluminum sheet for your project, it is crucial to consider its specific requirements, as each grade possesses its own strengths and limitations. Seeking advice from a knowledgeable supplier or expert can assist in determining the most suitable grade for your needs.

- Q: What are the different methods of polishing aluminum sheets?

- There are several methods for polishing aluminum sheets, including mechanical polishing, chemical polishing, and electro-polishing. Mechanical polishing involves using abrasives, such as sandpaper or polishing compounds, to physically remove imperfections and create a smooth surface. Chemical polishing utilizes a mixture of acids and other chemicals to dissolve the surface layer of the aluminum, resulting in a polished finish. Electro-polishing involves using an electric current to remove surface material and create a smooth, shiny surface. Each method has its own advantages and may be chosen depending on the desired finish and the specific requirements of the aluminum sheet.

- Q: Can aluminum sheets be used for signage?

- Yes, aluminum sheets can be used for signage. Aluminum is a versatile and durable material that is commonly used in the sign-making industry. It is known for its lightweight yet sturdy properties, making it ideal for outdoor and indoor signage. Aluminum sheets are resistant to corrosion, rust, and fading, ensuring that the signage will last for a long time. Additionally, aluminum can be easily cut and shaped into various sizes and designs, allowing for creative and customized signage solutions. The material also provides a smooth surface that can be painted, printed, or laminated with graphics and text, making it highly versatile for different signage applications. Overall, aluminum sheets are a popular choice for signage due to their durability, versatility, and aesthetic appeal.

- Q: Are aluminum sheets suitable for use in marine or saltwater environments?

- Yes, aluminum sheets are suitable for use in marine or saltwater environments. Aluminum has excellent corrosion resistance properties and is known for its ability to withstand the harsh conditions found in marine environments. Unlike many other metals, aluminum forms a protective oxide layer on its surface when exposed to oxygen, which helps prevent further corrosion. This oxide layer acts as a barrier, protecting the underlying metal from saltwater and other corrosive elements. Additionally, aluminum is lightweight yet strong, making it an ideal choice for marine applications where weight reduction is important. It is commonly used in the construction of boats, ships, offshore structures, and other marine equipment.

- Q: How do I calculate the weight of aluminum sheet? What is the density?

- The density of aluminum is 2.7g/cm^3.

Send your message to us

0.020 Aluminum Sheets - Aluminium Prepainted Coil with PVDF and Different Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords