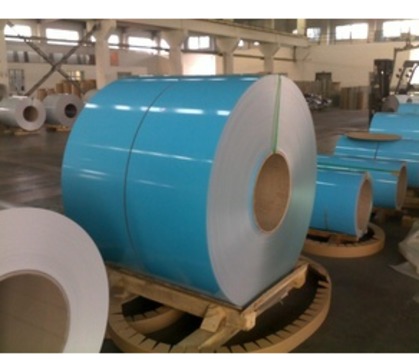

Aluminum Mill Coil - Prepainted Colorful Aluminum Coil and Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray, depending on the surface roughness. It is nonmagnetic and does not easily ignite. A fresh film of aluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (as much as 98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel. It is easily machined, cast, drawn and extruded.

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754, 5083,8011,etc

Temper:H14/16/18/22/24/32,HO etc.

Thickness:0.2mm—100mm

Width:100mm—2300mm (Can be slitted)

Inner Diameter: 508MM

CoilWeight:500kg-3000kg(Max.)

Application: Foil stock, Circles, Roofing, Canstock, Marine plate,Anti-sliperypurpose in vehicles, packing and appliance.

Specifications

aluminium coil for transformer winding with round edges and paper interleaf. ALUMINIUM COIL FOR TRANSFORMER WINDING

ALLOY | TEMPER | SPECIFICATION (MM) | |||

THICKNESS | I.D | O.D | WIDTH | ||

1050, 1050A 1060,1070 1070A,1350 |

O | 0.08---0.20 | 150, 300, 400 | 700--- --980 | 16.0--- ---1500.0 |

>0.20--1.50 | 150,205,300,350,400,500 | ||||

>1.50--3.00 | 300, 400, 500, 600 | ||||

Chemical Composition and Mechanical Properties

CHEMICAL COMPOSITION (Max) | |||||||||

Si | Fe | Cu | Mn | Gallium | Cr | Boron | Zinc | Ti+Van | |

0.10 | 0.40 | 0.05 | 0.01 | 0.03 | 0.01 | 0.05 | 0.05 | 0.02 | |

| |||||||||

UTS (Mpa) | ELONGATION

| At temperature of 20 deg. c | |||||||

RESISTIVITY Ω·mm²/M, max | CONDUCTIVITY%IACS, min | ||||||||

59--135 | 20% Min | 0.028035 | 61.5 | ||||||

WE HEREBY VERIFIED THAT THE GOODS ARE PRODUCED BY CNBM, WHICH HAS PASSED THE CERTIFICATION OF QUALITY SYSTEM FOR ISO9001.

- Q: Can we provide raw materials, aluminium coils and aluminum panels for several integrated ceilings?

- You go to my space, add my QQ bar, I do aluminum, aluminum coil, aluminum wafer, and I also want to know about the requirements of integrated ceiling ~ ha ha!

- Q: Are there any health or safety concerns related to aluminum coils?

- There are no significant health or safety concerns directly associated with aluminum coils. Aluminum is a common material used in various industries, including HVAC systems. It is lightweight, durable, and corrosion-resistant. However, it's important to ensure proper ventilation and avoid exposure to high concentrations of airborne aluminum dust or fumes, as excessive inhalation or ingestion might pose some health risks. Nonetheless, in typical applications, aluminum coils do not pose any significant health or safety concerns.

- Q: why is aluminum oxide used more frequently than silicon carbide as an abrasive?What r the different types of tool feed mechanism in USM process.

- Aluminium Oxide Grinding Wheel

- Q: If you were to make something from each of these.which is more expensive? aluminum or carbon fiber ?which is stronger?What would the advantages or disadvantages of each be?

- Oxidation: carbon fibre oxidise and looses strength as it oxidise. The oxidation level is quite low at room temperature but increases with temperature and also chemical contaminant Durability. as seen above CF will not have durability in time as you have with Aluminium. So be mindful as your product will not be as good in 10 years with CF as it is in Aluminium. Also failure mode with CF is much more difficult to predict, analyse and failure are not a controlled as Aluminium. CF will shatter when crack initiate from a minimal defect or chip.

- Q: Are there any environmental benefits to using aluminum coils?

- Yes, there are several environmental benefits to using aluminum coils. Firstly, aluminum is a highly sustainable material as it is 100% recyclable without losing its original properties. This means that using aluminum coils helps reduce the demand for mining and extracting new raw materials, reducing the environmental impact associated with these processes. Additionally, recycling aluminum requires only about 5% of the energy needed to produce primary aluminum, resulting in significant energy savings and reduced greenhouse gas emissions. Moreover, aluminum coils have a longer lifespan compared to other materials commonly used in coils, such as copper or steel. This durability means that fewer coils need to be manufactured and replaced over time, resulting in less waste generation and lower overall environmental impact. Furthermore, aluminum is corrosion-resistant, which eliminates the need for additional treatments or coatings that may contain harmful chemicals. This reduces the release of potentially hazardous substances into the environment during the manufacturing and use of aluminum coils. Lastly, aluminum is lightweight, which contributes to lower transportation costs and energy consumption during distribution. This aspect decreases fuel consumption and associated emissions, reducing the overall carbon footprint of using aluminum coils. Considering these factors, the use of aluminum coils provides significant environmental benefits, including reduced resource extraction, energy conservation, waste reduction, and lower emissions.

- Q: Can aluminum coils be used in high-radiation environments?

- Aluminum coils can be used in high-radiation environments, but their performance and durability may be affected depending on the level of radiation exposure. Aluminum is a relatively good conductor of heat and electricity, making it a suitable material for many applications, including coil systems. However, when exposed to high levels of radiation, aluminum can become more susceptible to degradation and corrosion. In high-radiation environments, the primary concern is the potential for radiation-induced damage to the material. Aluminum is considered to have relatively low radiation resistance compared to other metals, such as stainless steel or titanium. As a result, prolonged exposure to high radiation levels can lead to structural changes, including embrittlement and loss of mechanical properties. To mitigate these risks, several factors need to be considered. The specific radiation level, duration of exposure, and the intended application of the aluminum coils are critical in determining their suitability for use in high-radiation environments. Additionally, protective coatings or treatments can be applied to enhance the radiation resistance of the aluminum coils, increasing their durability and longevity. Ultimately, the decision to use aluminum coils in high-radiation environments should be based on a thorough assessment of the radiation levels, the potential risks, and the specific requirements of the application. Consulting with radiation experts and considering alternative materials may be necessary to ensure the best performance and safety in such demanding conditions.

- Q: What are the different alloy compositions used in aluminum coils?

- There are several different alloy compositions that are commonly used in aluminum coils, each with their own unique properties and applications. Some of the most frequently used alloy compositions include: 1. 1000 series alloys: These alloys are almost pure aluminum (with a minimum aluminum content of 99%), making them highly ductile and corrosion-resistant. They are often used in applications where high formability and good electrical conductivity are required, such as in electrical wiring and packaging. 2. 3000 series alloys: These alloys typically contain small amounts of manganese, making them stronger and more corrosion-resistant than the 1000 series alloys. They are commonly used in applications such as cooking utensils, chemical equipment, and decorative trim. 3. 5000 series alloys: These alloys contain magnesium as the primary alloying element, which significantly enhances their strength and hardness. They are known for their excellent resistance to corrosion and are often used in marine environments, as well as in the automotive and aerospace industries. 4. 6000 series alloys: These alloys are alloyed with magnesium and silicon, which results in improved strength, heat treatability, and weldability. They are commonly used in applications such as architectural and structural components, as well as in transportation and electrical conductors. 5. 7000 series alloys: These alloys are primarily composed of zinc as the main alloying element, which gives them exceptional strength and toughness. They are commonly used in high-stress applications such as aircraft structural components and sporting equipment. It's important to note that there are many other alloy compositions used in aluminum coils, each tailored to specific requirements and applications. The choice of alloy composition depends on factors such as desired strength, corrosion resistance, formability, and cost considerations.

- Q: How much is the rust-proof and thermal insulation aluminum coil?

- 3003 alumal alloy is the best and common rust-proof and thermal insulation aluminum coil. The price depends on the thickness and width you need.

- Q: Can aluminum coils be formed into different shapes?

- Aluminum coils possess the capability to assume diverse configurations. Such metal, known for its high malleability, exhibits an ability to undergo bending, shaping, and forming without fracturing. This particular attribute deems it an optimal material for myriad applications necessitating flexibility and adaptability. Aluminum coils, employing a myriad of techniques like bending, rolling, stamping, extrusion, or even specialized machinery like a coil forming machine, can be fashioned into an array of shapes. These shapes encompass sheets, plates, tubes, wires, or intricate three-dimensional structures. The capacity to mold aluminum coils into assorted forms renders it an exceptional choice for sectors such as construction, automotive, aerospace, and manufacturing, where customized parts and components are frequently required.

- Q: Can aluminum coils be used for food storage containers?

- Yes, aluminum coils can be used for food storage containers. Aluminum is a safe and commonly used material for food packaging due to its non-toxic, lightweight, and corrosion-resistant properties. It helps to preserve the freshness, flavor, and quality of food while also being recyclable and environmentally friendly.

Send your message to us

Aluminum Mill Coil - Prepainted Colorful Aluminum Coil and Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords