Painted Aluminum Sheets for Sale - Color Prepainted Aluminium Coils for Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

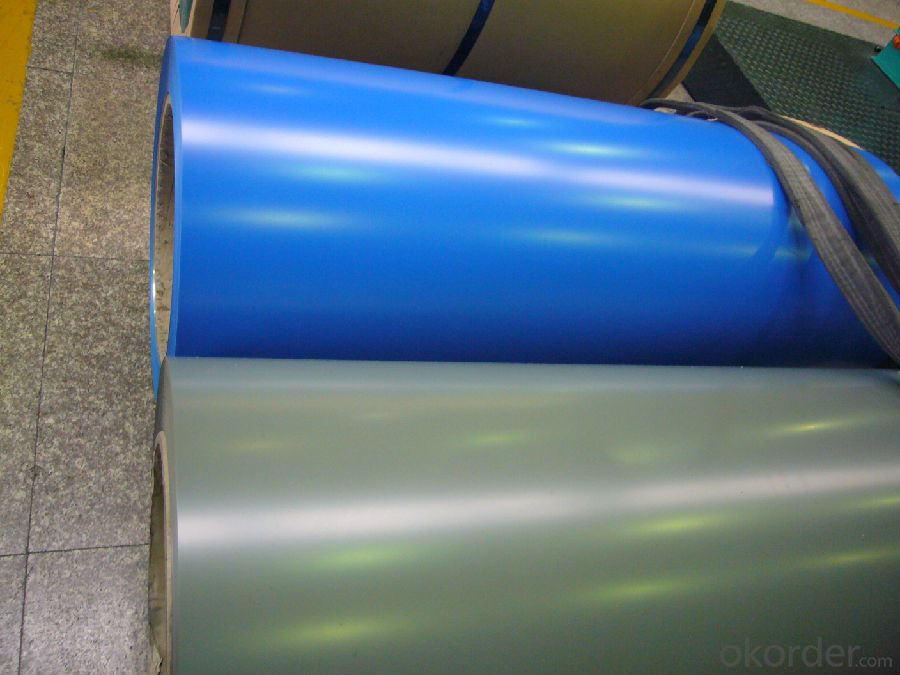

1.Structure of Color Prepainted Aluminium Coils for Composite Panel

Color Prepainted Aluminium Coils for Composite Panel is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Color Prepainted Aluminium Coils for Composite Panel

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Which is better, a water bottle made out of steel or one made out of aluminum?

- Unless okorder / A lightweight Nalgene BPA free water bottle

- Q: What are the different surface finishes for aluminum sheets in the construction industry?

- The construction industry presents various options for surface finishes on aluminum sheets. These finishes aim to improve the appearance and durability of the aluminum, making it suitable for diverse construction applications. One prevalent surface finish for aluminum sheets is the mill finish. This finish refers to the raw, untreated surface of the aluminum, which may exhibit minor imperfections or scratches. Mill finish finds common use in applications where appearance is not a significant concern, such as structural components or industrial projects. Another well-liked surface finish is the anodized finish. Anodizing involves an electrochemical process that forms a protective layer on the aluminum's surface, enhancing its resistance to corrosion and wear. Anodized finishes come in various colors, allowing for greater design flexibility in construction projects. They are commonly employed for architectural elements like window frames, facades, and decorative panels. Painted finishes are also frequently employed in the construction industry. Aluminum sheets can be coated with a layer of paint, providing aesthetic appeal and additional protection against corrosion. Painted finishes can be customized to meet specific design requirements, making them suitable for a wide range of construction applications. Additionally, brushed finishes find extensive use in the construction industry. Brushing is a mechanical process that creates a textured surface on the aluminum, resulting in a unique, matte appearance. This finish is commonly utilized for decorative purposes, such as interior wall panels or furniture in commercial spaces. In conclusion, the construction industry offers a range of surface finishes for aluminum sheets, including mill finish, anodized finish, painted finish, and brushed finish. Each finish possesses its own distinctive properties and advantages, enabling greater versatility and customization in construction projects.

- Q: How is aluminum sheet made?

- Aluminum sheet undergoes a rolling process to be manufactured, known as rolling. This process entails passing a preheated aluminum ingot through a succession of rolling mills. The initial step involves heating the ingot to a specific temperature to enhance its malleability. Once heated, the ingot is then fed through a sequence of rolling mills, wherein it is continuously pressed and stretched to reduce its thickness and increase its length. The rolling mills consist of a pair of rotating cylinders with grooves on their surfaces. As the ingot passes through these cylinders, it undergoes compression and elongation, resulting in a thinner and longer sheet. This process is repeated multiple times, with each pass further reducing the sheet's thickness. To maintain the desired thickness and dimensions, the sheet is periodically subjected to annealing. This process involves heating the sheet to a specific temperature and gradually cooling it. Annealing helps alleviate internal stresses and ensures the sheet retains its desired properties. Once the desired thickness is achieved, the aluminum sheet is cooled, trimmed, and either cut into specific lengths or rolled into coils for further processing or distribution. The final product is a flat, thin, and versatile sheet of aluminum that finds applications in various industries, including construction, automotive, packaging, and electrical appliances.

- Q: Is it feasible to recycle aluminum profiles after their use?

- <p>Yes, aluminum profiles can be easily recycled after use. Aluminum is one of the most recycled materials in the world due to its durability and recyclability. Recycling aluminum saves energy, as it requires only 5% of the energy needed to produce new aluminum from raw materials. The recycling process is straightforward, involving melting the aluminum, which can then be reformed into new products without losing its properties. This makes aluminum profiles an environmentally friendly choice for many applications.</p>

- Q: What is the shear strength of aluminum sheets?

- The shear strength of aluminum sheets varies depending on the specific alloy and temper of the material. Generally, aluminum alloys have a lower shear strength compared to steels but higher than most other non-ferrous metals. The shear strength can range from approximately 30 to 60 MPa (MegaPascals) for common aluminum alloys used in sheet form. However, it is important to note that these values can vary depending on factors such as thickness, surface finish, manufacturing process, and any heat treatments applied to the aluminum sheets. Therefore, it is recommended to consult the specific material datasheet or contact the manufacturer for accurate and detailed information on the shear strength of a particular aluminum sheet.

- Q: This question asks for a method to measure the thickness of an aluminum sheet.

- <p>To determine the thickness of an aluminum sheet, you can use a micrometer or a caliper, which are precise measuring tools. Place the sheet on a flat surface and measure from one side to the other at multiple points to account for any inconsistencies. Alternatively, you can use an ultrasonic thickness gauge, which is especially useful for non-contact measurements. For a quick estimate, a simple ruler can give you a rough idea, but for high precision, specialized tools are necessary. Always ensure the measuring device is calibrated and used correctly to get accurate results.</p>

- Q: Can aluminum sheets be used for flooring?

- Indeed, flooring can utilize aluminum sheets. Lightweight and sturdy, aluminum proves resistant to corrosion, rendering it an appropriate option for a range of flooring uses. Notably, aluminum sheets frequently find employment in industrial, commercial, and residential settings, encompassing warehouses, garages, kitchens, and outdoor areas. These sheets offer commendable strength, effortless installation, and minimal upkeep. Furthermore, aluminum flooring imparts a polished and contemporary aesthetic to any given space. Nevertheless, prudent consideration of factors like thickness, finish, and the unique demands of the flooring project becomes imperative prior to settling on aluminum sheets.

- Q: Are aluminum sheets conductive?

- Indeed, aluminum sheets possess conductivity. Being a metal, aluminum exhibits exceptional electrical conductivity. Consequently, aluminum sheets facilitate the smooth passage of electricity, rendering them suitable for an array of applications that necessitate conductivity, including electrical wiring, power transmission lines, and electronic devices.

- Q: It seemed in my experiment that aluminum wasn't reactive at all in the displacement reactions, except with copper sulfate. Is there a reason? or did I make a mistake? aluminum is more reactive than e.g silver nitrate, why didn't it react with it?

- Aluminium has a protective coating of Aluminium Oxide, this prevents many chemicals reaching the surface. This is because aluminium has a very strong affinity for oxygen and bonds to it with extremely strong bonds. It can be removed by dipping it carefully into a solution of Mercury (II) Chloride.

- Q: Are 101 aluminum sheets available in different finishes (e.g., brushed, polished)?

- Yes, 101 aluminum sheets are available in different finishes such as brushed and polished. These finishes are achieved through various processes that result in different textures and appearances on the surface of the aluminum sheets. Brushed finishes are created by brushing the surface of the sheet with an abrasive material, which creates a pattern of fine lines. This finish is commonly used to create a matte appearance. On the other hand, polished finishes are achieved by polishing the surface of the sheet to a high shine. This finish is often used to create a reflective and smooth surface. So, depending on the desired aesthetic or functional requirements, one can choose between brushed or polished finishes for 101 aluminum sheets.

Send your message to us

Painted Aluminum Sheets for Sale - Color Prepainted Aluminium Coils for Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords