Bj's Aluminum Foil Sheets - Prepainted Aluminium Coil with Bekker Paint PVDF

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coil Prepainted with Bekker Paint PVDF Description:

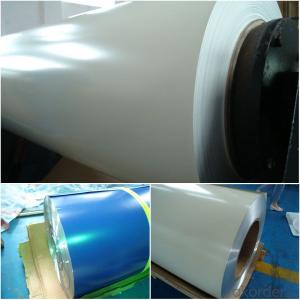

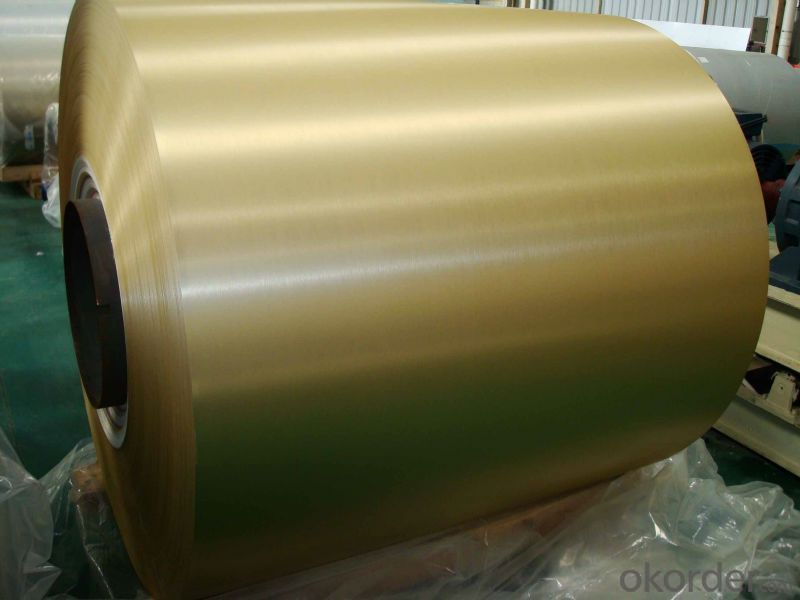

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coil Prepainted with Bekker Paint PVDF:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Coil Prepainted with Bekker Paint PVDF:

Aluminium Coil Prepainted with Bekker Paint PVDF Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Coil Prepainted with Bekker Paint PVDF:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South Africa;

- Q: Are aluminum sheets suitable for marine vessel construction?

- Indeed, marine vessel construction can make use of aluminum sheets. Aluminum, a material that is both lightweight and strong, offers excellent resistance to corrosion in marine environments. It is commonly utilized in the construction of various marine vessels, including boats, ships, and yachts. The use of aluminum sheets in marine vessel construction has a significant advantage in terms of its high strength-to-weight ratio. This allows for the creation of lighter vessels, which can lead to improved fuel efficiency, increased speed, and enhanced handling. Additionally, the lightweight nature of aluminum facilitates easier transportation and maneuverability during the construction process. Another notable benefit of utilizing aluminum sheets for marine vessel construction is their exceptional resistance to corrosion. Aluminum naturally develops a protective oxide layer on its surface, which prevents further oxidation and corrosion. This makes aluminum an ideal choice for marine environments, where vessels are constantly exposed to saltwater, humidity, and other corrosive elements. Moreover, aluminum sheets can be easily fabricated and welded, providing flexibility in the design and construction of marine vessels. They can be shaped into various forms, allowing for the creation of intricate hull structures and interior components. Aluminum also possesses good thermal conductivity, which aids in regulating temperature within the interior spaces of marine vessels. While aluminum sheets offer numerous advantages for marine vessel construction, it is important to consider certain factors. Aluminum is susceptible to galvanic corrosion when it comes into contact with certain metals, such as steel or bronze. Therefore, proper insulation and anti-corrosion measures should be implemented to prevent galvanic corrosion in aluminum-based vessels. In conclusion, aluminum sheets are highly suitable for marine vessel construction. Their lightweight nature, high strength-to-weight ratio, resistance to corrosion, and ease of fabrication make them an ideal choice for building durable and efficient marine vessels. However, it is crucial to take proper precautions to prevent galvanic corrosion when aluminum is used alongside other metals.

- Q: Are aluminum sheets suitable for construction purposes?

- Aluminum sheets are indeed appropriate for construction purposes. This material is lightweight and possesses an excellent strength-to-weight ratio, making it an optimal selection for various construction applications. It is resistant to corrosion, has a long-lasting nature, and boasts a high melting point, enabling it to withstand extreme weather conditions and fluctuations in temperature. Furthermore, aluminum sheets can be easily shaped, formed, and fabricated to fulfill specific construction requirements. They are commonly utilized in residential, commercial, and industrial buildings for roofs, wall cladding, window frames, doors, and other structural elements. In conclusion, aluminum sheets provide numerous benefits in the construction field, rendering them a fitting choice for a wide array of construction purposes.

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a highly durable and corrosion-resistant material, making it ideal for outdoor applications. It is lightweight, yet strong enough to withstand harsh weather conditions, such as rain, snow, and UV radiation. Additionally, aluminum sheets can be coated or painted to further enhance their resistance to corrosion and provide added protection against the elements. This makes them a popular choice for outdoor structures, signage, roofing, and other exterior applications where durability and longevity are essential.

- Q: Other then pop cans, what else is aluminum that can be recycled?

- all of it.

- Q: Are aluminum sheets suitable for construction applications?

- Yes, aluminum sheets are suitable for construction applications. Aluminum is a lightweight and durable material that is corrosion-resistant, making it ideal for various construction projects. It is commonly used for roofing, siding, and wall cladding, as well as in structural applications like beams and columns. Additionally, aluminum sheets offer excellent thermal and electrical conductivity, further enhancing their suitability for construction purposes.

- Q: What are the different methods for finishing the edges of aluminum sheets?

- There are several methods for finishing the edges of aluminum sheets, including deburring, chamfering, filing, sanding, and using edge trims or edge guards.

- Q: I'm buying a sword this afternoon for about 100 bucks i'm using it mainly to take pictures of and hang it on my wall. I looked up tips about buying swords and i think the sword i want is made out of aluminum. Could i use this sword as protection on an armed robber who would break into my house?

- a) yes it can be used for self defense, but it's going to be a stabbing weapon. Aluminum swords are garbage quality and are simply unable to hold a cutting edge, and b) There have been legal cases where people using stabbing weapons in perfectly justifiable self defense have been charged with manslaughter. The rationale was that if you're strong enough to kill someone with a stabbing weapon then you're strong enough to defend yourself (and not kill someone) without needing to use a stabbing weapon. This is crap that only a soft on crime liberal prosecutor could dream up. If I were you, I'd keep the aluminum sword on the wall, and if you can't afford a shotgun, then get a baseball bat. Those things will break bones, smash skulls, and otherwise bring an attack to an immediate end and since it's common sports equipment you'll look like you grabbed the first thing in desperation rather than you wanted to practice your Samurai skills the first chance you got. Just my .02 cents...

- Q: Are the aluminum sheets suitable for manufacturing window frames?

- Certainly, aluminum sheets are an ideal option when it comes to crafting window frames. Aluminum has gained widespread popularity as a material for window frames owing to its numerous beneficial characteristics. Notably, aluminum is both lightweight and sturdy, facilitating effortless installation and effectively combating corrosion. Moreover, aluminum boasts exceptional malleability, enabling diverse design opportunities and personalized modifications. Furthermore, aluminum window frames exhibit commendable thermal efficiency, exceptional noise attenuation, and demand minimal upkeep. Consequently, aluminum sheets emerge as a fitting and dependable choice for producing top-notch window frames.

- Q: How do aluminum sheets perform in terms of fatigue resistance?

- Aluminum sheets possess outstanding fatigue resistance, showcasing their ability to endure repeated stress and strain cycles without significant degradation in their mechanical properties. The exceptional fatigue resistance of aluminum sheets primarily stems from their microstructure, characterized by small and uniformly dispersed grains. This microstructure aids in the even distribution of applied stress throughout the material, effectively preventing crack formation and propagation. Moreover, fatigue resistance in aluminum sheets can be further enhanced through various processing techniques, such as heat treatment, alloying, and surface treatments. These techniques serve to refine the microstructure, enhance strength, and elevate the overall fatigue performance of the material. Furthermore, aluminum's relatively low density compared to other metals contributes to its superior fatigue resistance. This lower density enables improved energy absorption during cyclic loading, thereby reducing the likelihood of crack initiation and propagation. It is worth noting, however, that the fatigue resistance of aluminum sheets can vary depending on the specific alloy, temper, and thickness. Different aluminum alloys possess distinct mechanical properties and fatigue limits, necessitating the selection of the appropriate alloy and temper based on specific application requirements. In conclusion, aluminum sheets are highly esteemed for their remarkable fatigue resistance, making them a favored choice in industries that demand materials capable of enduring cyclic loading and extended service life.

Send your message to us

Bj's Aluminum Foil Sheets - Prepainted Aluminium Coil with Bekker Paint PVDF

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords