Microporous Insulation Board Available in a 7mm, 12.5mm and 25mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Microporous Insulation Board

CMAX Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

Features of Microporous Insulation Board

Extremely low thermal conductivity

High compressive strength

High thermal stability

Environment protection

Easy to handle

No harmful inhalable fibers

Resist most chemical attacks

Free of organic binders

Non combustible

Application of Microporous Insulation Board

Ladle

Torpedo Ladle

EAF

Degassers

Cement Rotary Kiln

Ceramic Firing Kiln

Aluminum Melting and Holding Furnace and so on

Working & Processing of Microporous Insulation Board

CMAX Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The microporous insulation board can be fixed in place with the same adhesives that are used for refractory lining.

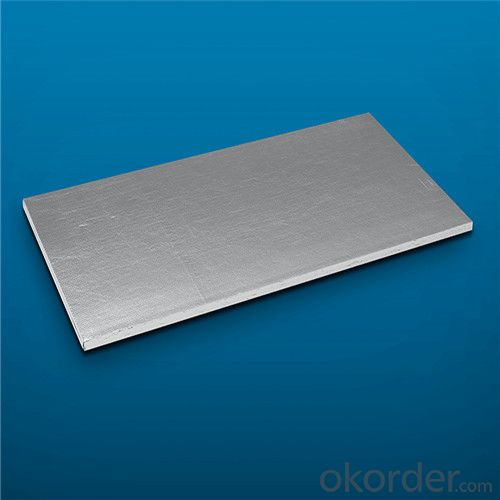

Image of Microporous Insulation Board

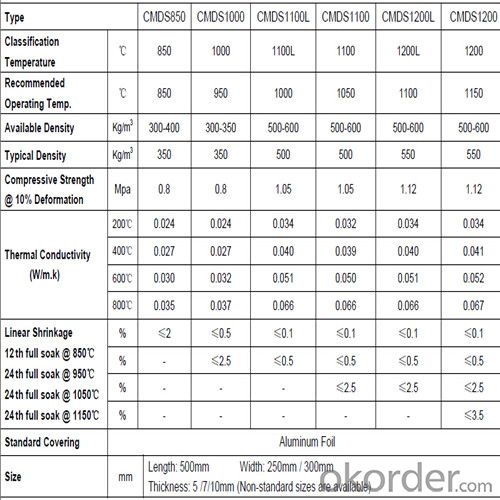

Technical Data of Microporous Insulation Board

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: What are the production methods of calcium silicate board material?

- The synthesis process of dynamic method is carried out under stirring, the synthesis temperature is higher than the static process, and under the compression condition. The dynamic method is simple, no gel chemical order, products made of small capacity, good performance, can obtain high temperature (1000 degrees Celsius) of xonotlite products and ultra light products, but the need for high pressure vessel with stirring device, equipment and process condition requires high energy consumption and investment are higher. At present, this method is adopted abroad.

- Q: What are the high temperature resistant insulation materials at 400?

- Thermal insulation materials for thermal equipment and pipes are mostly inorganic insulation materials. This kind of material has the characteristics of no decay, no burning, high temperature resistance and so on. For example: asbestos, diatomite, perlite, glass fiber, foam glass concrete, calcium silicate and so on.

- Q: Calcium silicate board for house ceiling, 6mm or 8mm?

- The calcium silicate board will not have the above shortcomings, the thickness of 15mm if it is the calcium silicate board 4mm ceiling 600*600 thickness can reach the effect of the biggest advantages of mineral wool board, calcium silicate board also is not a burning fire, moisture absorption is very good, green building materials.

- Q: What are the three major effects of fly ash in concrete?

- The "form effect" of fly ash contains many glass beads, the surface is smooth and the texture is dense. It is this form to water reducing effect, compact and homogeneous effect, can promote the early hydration of cement flocculation effect of solution, change the mixture rheological properties, the initial structure and hardening of the various functions, especially for pumping concrete, can play a good role in lubrication.

- Q: Calcium silicate board white ICI belongs to wood surface paint?

- No, it isn't。Calcium silicate board material properties should be comparable with cement products, usually referred to as cement board is actually calcium silicate board.

- Q: Why is calcium silicate board unsuitable for use in home improvement?

- It is not the appropriate material, calcium gypsum board to hemihydrate gypsum and organic silicone oil as the main material, the surface of the organic silicone oil with the installation way friction transportation will fall, a long time will get loss loss, if the poor quality of the organic silicone coating, it is not full proof effect is worse in the course of time, deformation, damp, moldy yes, yellow.

- Q: What's the use of white portland cement?

- All the raw meal with the proper components up to the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material, called white portland cement (the white cement).When grinding cement, allow limestone not to exceed 5% of the cement weight.Note: cement is allowed to be added to the grinding mill without damaging the cement properties. The amount of cement added shall not exceed 1% of the cement weight. The addition of additional substance must be tested and reported to the Ministry of construction materials for approval.

- Q: Eterpan and yinte in what is the difference?

- The silver plate refers to the calcium silicate board. Silver is a trademark, and calcium silicate board is the name of the product

- Q: What is the main role of fly ash added in concrete products?

- The workability of fresh concrete can be improved by adding fly ashThe workability of fresh concrete is affected by the volume, water cement ratio, gradation, shape and porosity of the aggregate. The fly ash is used for fresh concrete is the obvious benefits of increasing the slurry volume, slurry filled with aggregate between pores, inclusions and lubrication of aggregate particles, so that the concrete mixture has better cohesiveness and plasticity. The aggregate particles of fly ash can reduce the interfacial friction between the paste and aggregate, and improve the workability of the concrete mixture at the contact point of the aggregate.

- Q: What is a building energy-saving materials?

- Mainly include new wall materials, insulation materials, waterproof sealing materials, ceramic materials, new chemical materials, decoration materials and various industrial waste residue comprehensive utilization.

Send your message to us

Microporous Insulation Board Available in a 7mm, 12.5mm and 25mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords