High Temperature Resistant Calcium Silicate Pipe 650 Degrees Lightweight

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 7500 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Calcium Silicate Pipe:

It is a microporous structure inorganic hard ultra-light insulation material which is made of inorganic silicon and calcium as materials and treated by special techniques such as high temperature and high pressure hydrothermal reaction. It can maintain high temperature resistance at 650 °C to cope with temperature changes. The stability is long. The ultra-low chloride ion content has a good protection for the pipeline, and the pre-formed anti-deformation greatly enhances the service life.

Product application:

Our calcium silicate pipe are widely used in industries like heat supply network of city construction, metallurgy, petroleum, chemical, electronics, machinery and glass.

Equipment and pipeline facilities for petroleum refining, chemical, hydropower, nuclear power, thermal power, urban power grids

Advantages:

1.Good durability, can bear high temperature within the limit of continuous heat load.

2.Non-deformation within the temperature range.

3.Low thermal conductivity, in the whole range are used with unmatched adiabatic performance.

4.Light weight, high strength. It is the highest in these hard thermal insulation products.

5.Better durability, use for a long time without powder.

6.Construction with ordinary carpenter applicability, tools can be optional cut products.

7.Used safety, hygiene. Excluding asbestos, sulfur, chlorine such poisonous substances.

8.Fear water, but after drying also can be used.

| Calcium Silicate Pipe Size | |||

| Temperature | Size | ||

| ID(Inch) | ID(MM) | Thickness(MM) | |

| 650 or 1050 | 0.5-72 | 23-1836 | 25-100 |

| Other specifications can be customized according to customer requirements | |||

| Calcium silicate pipe index | ||||||

| Items | Unit | KRS-E | KRS-F | KRS-G | KRS-H | |

| Density | Kg/m3 | 220±10% | 220±10% | 250±10% | 850±10% | |

| Pressure Strength | Mpa | ≥0.6 | ≥0.62 | ≥0.72 | ≥17 | |

| Flexural Strength | Mpa | ≥0.35 | ≥0.38 | ≥0.41 | ≥8 | |

| Thermal Conductivity | 100℃ | W/(M.K) | ≤0.055 | ≤0.053 | ≤0.059 | ≤0.095 |

| 200℃ | ≤0.067 | ≤0.064 | ≤0.068 | ≤0.12 | ||

| 400℃ | ≤0.078 | ≤0.072 | ≤0.079 | ≤0.14 | ||

| 800℃ | // | ≤0.171 | ≤0.193 | ≤0.25 | ||

| Temp.Limit | ℃ | 650 | 1050 | 1050 | 1000 | |

| Linear Shrinkage | % | ≤2 | ≤2 | ≤2 | ≤2 | |

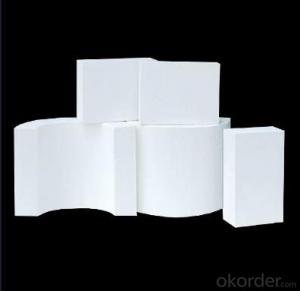

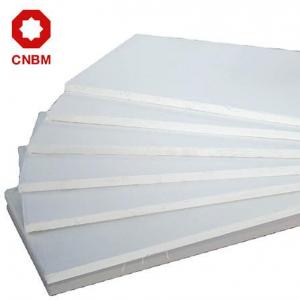

Products Pics:

FAQ:

Q: How can I get the price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q: Can I buy samples placing orders?

A: Yes.Please feel free to contact us.

Q: What is your lead time?

A: It depends on the order quantity and the season you place the order.Usually we can ship within 7-15 days for small quantity,and about 30 days for large quantity.

Q: What is your payment term?

A: T/T,Western Union,L/C,and Paypal.This is negotiable.

Q: What is the shipping method?

A: It could be shipped by sea,by air or by express(EMS,UPS,DHL,TNT,FEDEX and ect).Please confirm with us before placing orders.

- Q: Asbestos free calcium silicate board there is a crack in the kettle, what is the reason?

- Calcium silicate slab crack (crack was autoclaved late cooling stage, it refers to the irregular surface crack, calcium silicate board, or bright or dark is likely to cause fracture, calcium silicate board, low strength, appearance and performance is not up to the requirements)The main reason for the crack is to cool down too quickly.Solution: control the cooling rate, slow exhaust steam.The above is the calcium silicate board equipment in the production of prone to stick, blank, cracks and other phenomena of the reasons and solutions, if you encountered similar problems in production, you can have some reference.

- Q: What's the difference between white carbon and carbon black? Can they be replaced?

- Carbon black is the floorboard of white powder X- ray of amorphous silica and silicate products, mainly refers to the precipitated silica, fumed silica, ultrafine silica gel and gel, including powder synthetic aluminium silicate and calcium silicate. Silica is a porous material, its composition by SiO2 nH2O, where nH2O is there the surface hydroxyl form. Soluble in caustic and hydrofluoric acid, insoluble in water, solvent and acid (except hydrofluoric acid). High temperature resistant, non flammable, tasteless, odorless, has the very good electric insulation.

- Q: Calcium silicate board for house ceiling, 6mm or 8mm?

- Mineral wool board ceiling is different than the calcium silicate board ceiling. Or with the calcium silicate board, mineral wool board first big thickness, increase the keel pressure, easy to cause the ceiling of the cave. Second, it is easy to produce some bug mineral wool board. The fire performance of third mineral wool board no calcium silicate board, mineral wool board fourth dampeasily yellow, moisture absorption is not good.

- Q: What are the three major effects of fly ash in concrete?

- The "form effect" of fly ash contains many glass beads, the surface is smooth and the texture is dense. It is this form to water reducing effect, compact and homogeneous effect, can promote the early hydration of cement flocculation effect of solution, change the mixture rheological properties, the initial structure and hardening of the various functions, especially for pumping concrete, can play a good role in lubrication.

- Q: Cement is not silicate products

- So, we usually call cement as cementitious material - cement products

- Q: Eterpan and yinte in what is the difference?

- The silver plate refers to the calcium silicate board. Silver is a trademark, and calcium silicate board is the name of the product

- Q: What is the best price for the use of calcium silicate ceiling?

- Water will melt or become yellow, mildew. So if you choose their ceiling, you must first deal with the roof leak. Calcium silicate board with artificial and material prices of about 22 square meters, mainly for office space, and residential corridors and other public places decoration. Integrated ceiling is not afraid of water.

- Q: What's the difference between white cement and ordinary cement?

- White portland cement as the raw meal with the proper components till the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material. When grinding cement, allow limestone not to exceed 5% of the cement weight. White cement is mostly ornamental, and its manufacturing process is much better than ordinary cement. The gap is mainly used to hook white tiles, is generally not used in the wall, the reason is not high strength. It is available in the building materials market or decoration materials shop.

- Q: What is the main role of fly ash added in concrete products?

- The workability of fresh concrete can be improved by adding fly ashThe workability of fresh concrete is affected by the volume, water cement ratio, gradation, shape and porosity of the aggregate. The fly ash is used for fresh concrete is the obvious benefits of increasing the slurry volume, slurry filled with aggregate between pores, inclusions and lubrication of aggregate particles, so that the concrete mixture has better cohesiveness and plasticity. The aggregate particles of fly ash can reduce the interfacial friction between the paste and aggregate, and improve the workability of the concrete mixture at the contact point of the aggregate.

- Q: What are the exterior walls of the building besides the benzene board and the extruded board?

- Foam heat insulation material mainly includes two categories, polymer foam type insulation material and foam asbestos insulation material. Polymer foam thermal insulation material has the advantages of small absorption rate, stable heat preservation effect, low thermal conductivity, no dust flying in construction, easy construction, etc., and it is in the period of popularization and application.

Send your message to us

High Temperature Resistant Calcium Silicate Pipe 650 Degrees Lightweight

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 7500 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches