Rzr Xp 1000 Aluminum Skid Plate

Rzr Xp 1000 Aluminum Skid Plate Related Searches

Aluminum Skid Plate Rci Aluminum Skid Plate Aluminum Anti Skid Plate Trd Aluminum Skid Plate Scx10 Aluminum Skid Plate Tj Aluminum Skid Plate Jeep Tj Aluminum Skid Plate Ktm Aluminum Skid Plate S10 Aluminum Skid Plate Axial Wraith Aluminum Skid Plate Fj Cruiser Aluminum Skid Plate Aluminum Skid Plate Jeep Jk Wraith Aluminum Skid Plate Focus Rs Aluminum Skid Plate E46 Aluminum Skid Plate Mazda 3 Aluminum Skid Plate E Revo 2.0 Aluminum Skid Plate Tacoma Aluminum Skid Plate Non Skid Aluminum Plate Ford Focus Aluminum Skid Plate Aluminum Skid Plate 4runner Aluminum Skid Plate Thickness Aluminum Skid Plate Tacoma 4runner Aluminum Skid Plate E92 M3 Aluminum Skid Plate Focus St Aluminum Skid Plate Aluminum Kick Plate Aluminum Anti Slip Plate Aluminum 1100 Plate Aluminum Ramp PlateRzr Xp 1000 Aluminum Skid Plate Supplier & Manufacturer from China

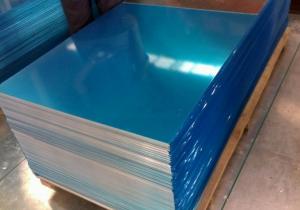

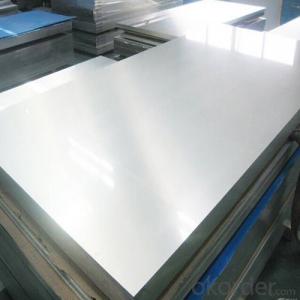

The Rzr Xp 1000 Aluminum Skid Plate is a high-quality protective accessory designed specifically for the RzR XP 1000 model, providing essential protection to the vehicle's undercarriage. This durable aluminum skid plate is engineered to safeguard the vehicle's critical components from debris, rocks, and other potential hazards encountered during off-road adventures. The Rzr Xp 1000 Aluminum Skid Plate is an indispensable addition for any off-road enthusiast, ensuring the longevity and performance of their RZR XP 1000 in various terrains and conditions.The Rzr Xp 1000 Aluminum Skid Plate is widely used in off-roading and racing events, where the vehicle's underside is exposed to potential damage from rough terrain. By installing this skid plate, drivers can confidently navigate through challenging landscapes without worrying about the safety of their vehicle's undercarriage. This protective accessory is designed to withstand the rigors of off-road driving, offering a reliable solution for those who frequently engage in outdoor adventures.

Okorder.com is a leading wholesale supplier of the Rzr Xp 1000 Aluminum Skid Plate, offering a vast inventory of this essential accessory to customers worldwide. With a strong commitment to quality and customer satisfaction, Okorder.com ensures that each Rzr Xp 1000 Aluminum Skid Plate is manufactured to the highest standards, providing a reliable and long-lasting solution for off-road enthusiasts.

Hot Products