Diamond Tread Plate Aluminum Sheets - Die Cast 1050 1060 1070 1100 1200 Aluminum Plate for Aluminum Cookware

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Die Cast 1050 1060 1070 1100 1200 Aluminum Plate for Aluminum Cookware

Professional aluminum product manufacturer

We have our own plant , Laboratory and engineer

Over 100 models can totaly satisfy your request

As powerful and stronger factory, our aluminum quality is very stable and reliable

2 years warranty period

Specifications:

Thickness:0.5mm-6.0mm

Width:100mm-900mm

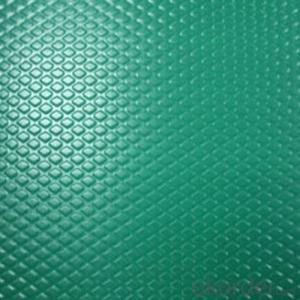

Surface:Bright & smooth surface, not defects like white rust, oil patch.

Product Information :

Product | Aluminum Circle |

Alloy | 1050 1060 1070 1100 1200 |

Temper | O, H12, H14, H18 and H24... |

Thickness | 0.5mm-6.0mm |

Diameter | 100mm-900mm |

Lead Time | Within 30-45 days after receiving deposit |

Packing | Standard Exporting wooden pallets or based on customer requirement |

Material | Using high-tech machinery utilizing premium grade Aluminium Coil. Customized according to the needs and demands of the clients these can be availed at different technical specifications. |

Surface: | Bright & smooth surface, free from defects like white rust, oil patch, edge damage. |

Application | Aluminium Circles are used in Reflective Sign Boards, Road Furniture, Utensils, Sand witch Bottom, Cooker, Non-Stick etc. |

- Q: the amp setting when welding aluminum tig? and what color should the electrode feeder be bronze or chrome grey? u know the one u use with your hands

- Best electrodes to use for Aluminum welding is 1.5% lanthanum oxide (gold color code.). 2% zirconia (brown) or 2% thorium oxide (red) can also be used. Note that zirconia-doped electrodes should never be used for DC welding. A lot of welders like to quote offhand the rule 1 amp for every 0.001 inch of thickness. This applies to steel, stainless, and nickel alloys only. Due to the lower melting point, lower specific heat capacity, and higher thermal conductivity of of Al, this rule should NOT be used for Al! I recommend welding a test piece first with the same joint configuration and thickness of the part you intend to weld. Note that fillet welds require more current than butt welds or edge welds. Start out by using 2/3 amp per 0.001 of thickness, in other words, reduce the current of the above rule by about 30-40% . Make 3 test weld, then check to see if there's any visible penetration on the other side. If you don't see any through-pentration at all, increase the current by about 10-20 amps and test again.

- Q: How are aluminum sheets cleaned and maintained?

- Aluminum sheets can be effectively cleaned and maintained with a few simple steps. To begin, it is important to remove any loose dirt or debris from the surface of the sheets. This can be done by using a soft brush or cloth to gently sweep away the particles. Next, a mild detergent solution can be prepared by mixing a small amount of dish soap or a specialized aluminum cleaner with warm water. This solution should be applied to the sheets using a soft sponge or cloth. It is important to avoid using abrasive materials or cleaners that contain harsh chemicals, as these can cause damage to the aluminum surface. After applying the detergent solution, the sheets should be thoroughly rinsed with clean water to remove any residue. It is important to ensure that all soap or cleaner is completely removed, as any remaining residue can lead to staining or discoloration over time. Once the sheets are clean, they should be dried using a clean, soft cloth or towel. This will help to prevent water spots or streaks from forming on the surface. It is important to avoid using abrasive materials or rubbing too vigorously, as this can scratch the aluminum. In terms of maintenance, it is recommended to regularly inspect the aluminum sheets for any signs of damage or corrosion. If any areas are found to be damaged, they should be repaired or replaced as soon as possible to prevent further deterioration. Additionally, it is beneficial to apply a protective coating to the aluminum sheets. This can be done using a specialized aluminum sealant or a clear lacquer. This coating will help to protect the surface from environmental factors such as moisture, sunlight, and pollutants. Overall, cleaning and maintaining aluminum sheets involves regular gentle cleaning with a mild detergent solution, thorough rinsing, and drying with a soft cloth. Additionally, inspecting for damage and applying a protective coating can help to prolong the lifespan and appearance of the sheets.

- Q: Don't you know how you can grind a pair of scissors along a piece of paper to make it curly? Would that work with aluminum foil? I have to make a sculpture for my 3D class and I need to know if this would work before I go off and buy any.

- The answer to your two questions is that aluminum foil cut long and narrow is very weak and further weakened by its tendency to have slight tears on the edge in cutting due to stress. Aluminum foil will curl when pulled over an edge but it has to be done very carefully to keep it from tearing and has very little spring to it - a slight touch will flatten it. Although it would be a little extreme and sharp, you could cut narrow pieces off of thin aluminum sheet - soda cans or flashing used for valleys on roofs and which will curve in cutting and have enough stiffness to hold the shape. And cost more

- Q: Can aluminum sheets be used for automotive heat shields?

- Yes, aluminum sheets can be used for automotive heat shields. Aluminum is a popular choice for heat shields in the automotive industry due to its excellent thermal conductivity and heat resistance properties. It has a high melting point and can effectively dissipate heat, making it suitable for protecting various components from excessive heat exposure. Additionally, aluminum sheets are lightweight and easy to shape, allowing for custom designs to fit specific automotive applications. Overall, aluminum sheets are a reliable and cost-effective option for automotive heat shields.

- Q: What is the standard size of an aluminum sheet?

- Depending on the specific application and industry, the standard size of an aluminum sheet may vary. However, typically, aluminum sheets come in commonly found standard sizes such as 4 feet by 8 feet or 48 inches by 96 inches. These dimensions are extensively used in various industries like construction and manufacturing due to their adaptability and compatibility with standard equipment and processes. Nevertheless, it is crucial to acknowledge that aluminum sheets can also be personalized by cutting or ordering them in different sizes to fulfill specific project necessities.

- Q: Are aluminum sheets resistant to abrasion?

- Yes, aluminum sheets are generally resistant to abrasion due to their hardness and durability.

- Q: Can aluminum sheets be bent or formed?

- Yes, aluminum sheets can be bent or formed. Aluminum is a highly malleable and ductile metal, which means it can easily be shaped or bent without breaking. This characteristic makes it a popular choice for various applications, such as manufacturing automotive parts, aircraft structures, and household items. Aluminum sheets can be bent or formed using various techniques, such as press braking, roll bending, and stretch forming. These methods allow the aluminum sheets to be shaped into different angles or curves to meet specific design requirements.

- Q: What are the fire-resistant properties of aluminum sheets?

- Aluminum sheets offer impressive fire-resistant qualities, making them an ideal choice for different applications that prioritize fire safety. The primary explanation for their fire resistance lies in the natural formation of a unique oxide layer on the aluminum's surface when exposed to oxygen. This layer acts as a protective barrier, preventing further oxidation and reducing the likelihood of combustion. Not only is the oxide layer on aluminum sheets highly stable, but it also boasts a high melting point. Consequently, it can endure high temperatures without melting or catching fire, rendering it flame-resistant. Additionally, the oxide layer acts as an effective thermal insulator, slowing down heat transfer and impeding the spread of fire. Another benefit of aluminum sheets is their low flammability. Aluminum is a non-combustible material, meaning it does not burn or support combustion. This characteristic proves especially advantageous in situations where fire containment and prevention are critical. Furthermore, aluminum sheets possess exceptional heat dissipation capabilities. They swiftly disperse heat away from the source, minimizing the risk of overheating and potential fire hazards. This makes them suitable for various heat-intensive applications, including electrical enclosures, automotive parts, and industrial machinery. In conclusion, aluminum sheets demonstrate remarkable fire-resistant qualities due to the protective oxide layer, non-combustible nature, and efficient heat dissipation. These attributes make them highly sought after for applications that prioritize fire safety, offering reassurance and safeguarding against potential fire incidents.

- Q: What is the yield strength of aluminum sheets?

- The yield strength of aluminum sheets can vary depending on the specific grade and thickness of the sheet. However, on average, aluminum sheets have a yield strength ranging from 14,000 to 24,000 pounds per square inch (psi).

- Q: Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually part of the housing for my cell phone so doing it like this would probably not be right and the paint would probably wear out. I am mainly interested in finding out what kind of paint to use, what tools i need, and how to achieve an extremely! durable! matte finish because this phone is thrown around and going in and out of my pocket the paint will have to withstand getting rubbed down everyday by my pockets.That was a very long question, thanks for bearing with me and thanks in advance for those who provided me with an answer/thought. THANKS!

- Spray paint, often Enamel, is pretty tough by itself, but I see your concern about it abrading in your pocket or by continuous use. There's a couple of things you can do to help with the wear and tear. Firstly, painting on Aluminum is great. You'll have no adhesion problems with the paint, so long as the aluminum is not polished (mirror finished) If it is, you need to scratch it a bit in order to allow the paint something to grab on to. You can use the same stencil you will eventually paint with to apply an etching solution (Etch I-M) so you don't mess up the finish on other parts of the phone. Or you can sand it with 0000 steel wool (that's 4-aught steel wool...), which is really really fine sanding. If the aluminum is 'sanded' or 'brushed' then you're probably good to go, just make sure that there is not a clear coat on the aluminum. If there is, then do the etching or sanding to it as well to get that clear coat off. You want to paint directly onto the aluminum. Once you spray your stencil with the paint of your choice over the etched or prepared surface, you should have a very durable finish. However, since you want it to be uniformly Matt, I'd say that you should find a good, high quality Matt spray varnish or topcoat. Lacquer is good (Varathane, Deft) and durable, and importantly, youcan always throw on another clear coat if the wear and tear is getting to the design. One thing: DON'T RUSH THE PAINTING! Allow enough time for each coat to dry completely, and once finished, let the final clear coats dry absolutely perfectly before handling the phone too roughly. Do some of this and your phone will look great. hope that helped...

Send your message to us

Diamond Tread Plate Aluminum Sheets - Die Cast 1050 1060 1070 1100 1200 Aluminum Plate for Aluminum Cookware

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords