Aluminum Checkered Plate - China Supply Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product Introduction

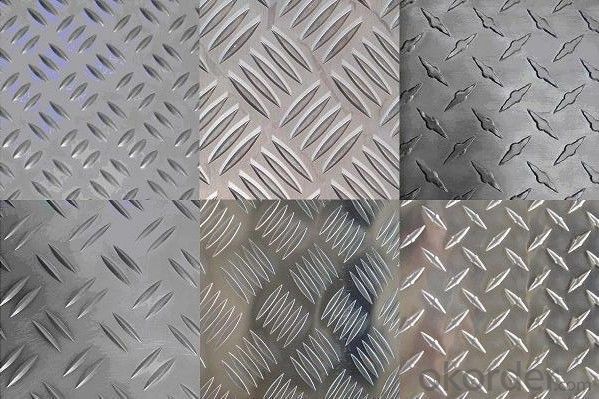

1) Temper of Aluminum tread plate: H12 H14 H16 H18 H22 H22 H24 H26 H32 H36 H38 0 etc

2) Alloy: 1100 1050 1060 1070 3008 3150 5052 5754 5082 5083 6063 6061

3) Packing of the Aluminum tread plate: export standard, wooden pallet in horrizental or vertical

4) Origin; China

5) Sheet specifications: Thickness0.2-10mm width of Aluminum treadpleat less than 2400mm according to the customer's specifications

6) Minimum order quantity:5 tons for each size

7) Lead time: within 30days

8) The terms of payment: T/T D/P L/C

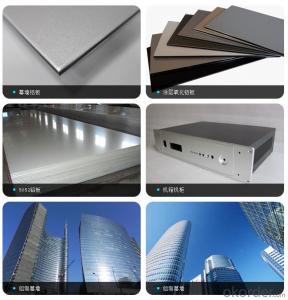

9) Application: construction decoration and curtain

10) Remarks of pannel base plate: specific requirments of alloy temper or specifications can be disscussed at the buyer's requirments.

l Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet

Delivery detail: About 25-35days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

l CNBM World Wide

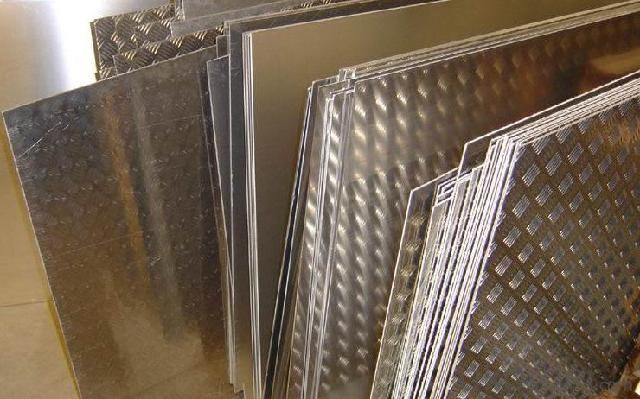

l Product Images

l Application

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email:service@okorder.com

- Q: Is aluminum a suitable material for use in nuclear power plants?

- <p>Yes, aluminum can be used in nuclear power plants, but its application is limited due to its reactivity with neutrons. Aluminum is used in non-nuclear grade components such as cooling systems, electrical equipment, and structural supports. However, it is not used in the core or in high-radiation areas due to its tendency to absorb neutrons, which can lead to transmutation and the production of radioactive isotopes. Materials like stainless steel, zirconium alloys, and other neutron-resistant materials are preferred for core components and high-radiation environments.</p>

- Q: This question asks about the amount of energy needed to produce aluminum.

- <p>The energy required for the production of aluminum is substantial. Producing one ton of aluminum typically requires around 15-25 kilowatt-hours of electricity, largely due to the process of electrolysis, which is used to extract aluminum from its ore, bauxite. This high energy consumption is a significant factor in aluminum production costs and environmental impact. The energy required can vary based on the efficiency of the smelting process and the source of electricity used.</p>

- Q: Explain the distinction between primary and secondary aluminum recycling, including the processes involved in each.

- <p>Primary aluminum recycling involves the production of aluminum from bauxite ore through a process called electrolysis. This process is energy-intensive and requires significant resources. Secondary aluminum recycling, on the other hand, involves the recycling of aluminum products back into new aluminum products. This process is much more energy-efficient as it involves melting and recasting the aluminum, which requires only 5% of the energy needed for primary production. Secondary recycling is more sustainable and environmentally friendly due to its lower energy consumption and reduced waste.</p>

- Q: Explain how the inclusion of copper impacts the characteristics of aluminum alloys.

- <p>The addition of copper to aluminum alloys significantly enhances their strength and hardness. Copper is one of the most effective alloying elements for aluminum, leading to the formation of a series of age-hardenable alloys known as the 2xxx series. These alloys, such as 2024, are characterized by their high strength-to-weight ratio and are often used in aerospace applications, structural components, and transportation equipment. The copper atoms in the aluminum matrix form precipitates that strengthen the alloy through a process called precipitation hardening. However, the addition of copper also reduces the alloy's ductility and corrosion resistance, necessitating careful control of the copper content and heat treatment processes to optimize the alloy's properties for specific applications.</p>

- Q: This question asks if there are differences in how long different types of aluminum cookware can last.

- <p>Yes, there are differences in the durability of different types of aluminum cookware. Anodized aluminum cookware is more durable and resistant to scratches and corrosion compared to non-anodized aluminum. Cast aluminum cookware is heavier and more durable than aluminum clad cookware, which is a layer of aluminum bonded to a stainless steel core. The thickness of the aluminum also affects durability, with thicker aluminum being more resistant to warping and lasting longer. Proper care and maintenance also play a significant role in the longevity of aluminum cookware.</p>

- Q: Is it possible to develop allergies from exposure to aluminum found in food packaging materials?

- <p>While aluminum is commonly used in food packaging materials, the risk of allergic reactions to aluminum is generally low for most people. Aluminum is not a known allergen, and exposure through packaging is typically minimal. However, individuals with a rare condition called contact dermatitis may experience skin irritation from aluminum. For the general population, the risk of allergic reactions due to aluminum in food packaging is negligible. It's always important to monitor any unusual reactions and consult a healthcare professional if concerned.</p>

- Q: Is aluminum capable of functioning as a catalyst in chemical reactions?

- <p>Aluminum is not typically used as a catalyst in chemical reactions. Catalysts are substances that increase the rate of a chemical reaction without being consumed in the process. Aluminum, being a metal, does not have the properties necessary to act as a catalyst in most reactions. However, it can be used in certain reactions as a reducing agent or in the form of organoaluminum compounds, which may participate in catalytic processes, but these are not common applications.</p>

- Q: Are aluminum alloys suitable for use in the aerospace industry?

- <p>Yes, aluminum alloys are extensively used in aerospace applications due to their high strength-to-weight ratio, corrosion resistance, and good fatigue characteristics. They are particularly favored for constructing airframes, wings, and other structural components where weight savings are critical. The alloys are also used in manufacturing engine parts and heat exchangers due to their thermal conductivity and ability to withstand high temperatures. However, the specific alloy selection depends on the particular requirements of the application, such as temperature resistance, strength, and environmental conditions.</p>

- Q: This question asks about the impact of adding zinc to aluminum alloys and how it changes their characteristics.

- <p>Adding zinc to aluminum alloys significantly enhances their mechanical properties, particularly strength and hardness. Zinc increases the alloy's resistance to deformation, making it more suitable for applications requiring high strength-to-weight ratios. This addition also improves the alloy's resistance to corrosion, especially in marine environments. However, it's important to note that excessive amounts of zinc can lead to a decrease in ductility and increase the risk of cracking, especially during welding or heat treatment processes. The addition of zinc also affects the alloy's thermal conductivity and electrical conductivity, typically reducing both. Overall, the addition of zinc to aluminum alloys is a balancing act to achieve desired properties for specific applications.</p>

- Q: This question asks for the specific temperature at which aluminum changes from a solid to a liquid state.

- <p>The melting point of aluminum is approximately 660.32 degrees Celsius (1220.58 degrees Fahrenheit). This is the temperature at which solid aluminum begins to melt and transform into a liquid state.</p>

Send your message to us

Aluminum Checkered Plate - China Supply Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords