Skid Aluminum Coil for Coated Aluminum Honeycomb Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

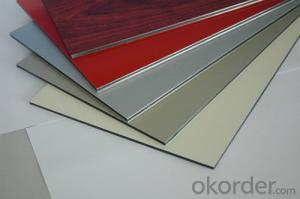

Coated Aluminium Coil/Roll For Aluminium Honeycomb Panel

Description

Alloy | 1060, 1100, 3003, 8011, etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.05mm to 3.0mm |

Width | Standard width:1240mm |

Special width:1300mm, 1520mm, 1570mm, 1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, ACRYLIC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness(pencil resistance) | More than 2h |

Coating adhesion | 5J (EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility(T-bend) | 2T |

MEK resistance | More than 100 |

Advantage | 1.High temperature resistant 2.Weathering resistant 3.Scrubbing resistant 5.Acid or alkali proof 6. Fireproof 7.Light weight material is easy to construct and install |

Out package | Wooden splint with export standard |

Application | ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels, etc |

Manufacturing

Decoiler → Accumulator →Tension Leveler →Acid & Alkali Cleaner → Rinse →Conversion Treatment → Priming coater →Infrared Curing Oven →Main coater →Floatation Curing Oven →Strippable Film Applicator → Exit Accumulator → Recoiler

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: Can aluminum coils be painted?

- Yes, aluminum coils can be painted. However, it is important to follow proper surface preparation and use a suitable paint that is compatible with aluminum to ensure a long-lasting and durable finish.

- Q: Are there any limitations on the coil flatness of aluminum coils?

- Aluminum coils, like other metal coils, have limitations on their flatness. The flatness of a coil refers to the extent to which its surface deviates from being completely flat. The American Society for Testing and Materials (ASTM) has set standards for measuring and evaluating the flatness of metal coils, including aluminum coils. These standards provide guidance for manufacturers, suppliers, and customers in determining the acceptable level of flatness for a particular application. The acceptable flatness of aluminum coils can vary depending on factors such as coil thickness, aluminum grade, and intended use. Thinner coils generally have stricter flatness requirements than thicker ones due to their greater susceptibility to distortion and waviness. Coil manufacturers employ various techniques, such as tension leveling, roller leveling, and corrective leveling, to control and improve flatness. These processes help to minimize or eliminate any deviations in flatness that may occur during coil manufacturing or processing. It is important to understand that achieving perfect flatness in aluminum coils is not always possible due to the inherent properties of the metal. Aluminum tends to exhibit some degree of natural springback, which can result in slight variations in flatness. However, these variations typically fall within acceptable tolerances for most applications. Ultimately, the limitations on the flatness of aluminum coils depend on the specific requirements of the customer or industry. Effective communication and clear establishment of flatness specifications between manufacturers and suppliers are crucial to ensuring that the coils meet the desired quality standards.

- Q: Four roller rolling mill roller bearing on the aluminum top how always have holes, in the production process, will be printed on just above the work roll, the work roll used in less than a day, it will produce a pothole, and aluminum plate will be printed from the upper supporting roller above the straight line, the line in the above there are holes.

- Well, typical aluminum plate surface defects in the backup roll print, solution, change support roll.Do not know your factory function division, should have special polishing work roll, support roller grinding workshop, this problem should be addressed to them, sticks are not qualified, how can dry out qualified products?

- Q: Can aluminum coils be recycled?

- Indeed, it is possible to recycle aluminum coils. Due to its exceptional recyclability, aluminum stands as one of the frequently recycled materials. The procedure for recycling aluminum coils encompasses melting them to eliminate impurities and subsequently molding them into fresh products or coils. By recycling aluminum coils, not only are natural resources preserved, but also energy consumption and greenhouse gas emissions are diminished relative to the production of new aluminum from primary materials.

- Q: What are the advantages of using aluminum coils over other materials?

- There are several advantages of using aluminum coils over other materials. Firstly, aluminum is a lightweight material, making it easier to handle and transport. This lightweight nature also makes it more cost-effective as it requires less energy to manufacture and install. Secondly, aluminum has a high level of corrosion resistance. It does not rust, even when exposed to harsh environmental conditions, making it suitable for outdoor applications. This durability ensures a longer lifespan and reduces maintenance costs in the long run. Additionally, aluminum coils provide excellent heat transfer properties. They have a high thermal conductivity, allowing for efficient heat exchange. This makes them ideal for applications such as heating, ventilation, and air conditioning systems, where effective heat transfer is crucial. Moreover, aluminum is a highly recyclable material. It can be recycled repeatedly without losing its quality or performance. This not only reduces waste and contributes to environmental sustainability but also lowers production costs. Lastly, aluminum coils offer versatility in terms of design and customization. They can be easily formed, shaped, and coated to meet specific requirements. This flexibility allows for a wide range of applications in various industries, from automotive and construction to electronics and aerospace. Overall, the advantages of using aluminum coils, including its lightweight nature, corrosion resistance, heat transfer properties, recyclability, and versatility, make it a preferred choice over other materials.

- Q: What are the different joining methods for aluminum coils?

- Depending on the specific application and desired bond strength, there are multiple methods available for joining aluminum coils. Some commonly used techniques include: 1. Welding: TIG welding, MIG welding, and laser welding are all viable options for welding aluminum coils. These methods create a robust and long-lasting bond that ensures structural integrity. 2. Brazing: By melting a copper-based alloy filler material, two aluminum coils can be joined together. Brazing is particularly useful for joining thin aluminum coils and provides a strong and leak-proof connection. 3. Adhesive bonding: This non-destructive method involves using a high-strength adhesive to bond the aluminum coils. Adhesive bonding is often preferred for applications where aesthetics and surface finish are vital, as it does not leave any visible welding or brazing marks. 4. Mechanical joining: Techniques such as riveting, clinching, and using fasteners like screws or bolts are categorized under mechanical joining. These methods offer a reliable and easily reversible bond, making them suitable for applications that require disassembly. 5. Roll bonding: Roll bonding is a process that involves passing two or more aluminum coils through a rolling mill under high pressure, resulting in the creation of a single composite coil. This method is commonly employed for joining dissimilar metals or creating laminated structures with different alloy combinations. Each joining method has its own advantages and limitations, and the choice depends on factors such as desired strength, cost, production volume, and specific application requirements. It is crucial to carefully consider these factors to ensure the most appropriate method is selected for aluminum coil applications.

- Q: The company wants to produce an aluminum coil production line, which is better for large aluminium smelting equipment?

- Dongpu heat well, they have the qualification certificate issued by the state kiln construction, as far as I know, their melting furnace Aluminum Alloy 'plan is very good, and the operation is simple and safe, feel good, can be wiped off

- Q: Is it possible to utilize aluminum coils in creating art pieces or decorative items?

- <p>Yes, aluminum coils can be used to make artworks or decorations. Aluminum's malleability and durability make it an excellent material for crafting. It can be bent, twisted, and shaped into various forms, allowing for creative expression in art and design. Additionally, aluminum's resistance to corrosion and weathering makes it suitable for both indoor and outdoor decorative pieces. Artists often appreciate its lightweight nature and the metallic finish that can be polished or painted, offering versatility in artistic applications.</p>

- Q: Can aluminum coils be coated with protective films?

- Coating aluminum coils with protective films is a prevalent practice across industries. These films, typically composed of materials like polyester or polyethylene, are applied to the coils using adhesive or heat bonding. Their main purpose is to safeguard the coils from damage, scratches, or corrosion during storage, transportation, or processing. Acting as a barrier, the films shield the coils from moisture, dirt, chemicals, and other external factors. Some protective films even offer temporary UV protection. Ultimately, this practice guarantees the preservation of the coils' quality and integrity throughout their handling and usage.

- Q: 11 g of aluminum at 200 C and 19 g of copper are dropped into 55 cm^3 of ethyl alcohol at 15 C. The temperature quickly comes to 24 C. What was the initial temperature of the copper? (answer in C) Express your answer using two significant figures.

- Example Problem Statement: An aluminum wing on a passenger jet is 29 m long when its temperature is 29°C. At what temperature would the wing be 7 cm (0.07 m) shorter? Step 1: Write down what you know in symbolic form: The wing is made of aluminum, therefore: α = 25 x 10-6 /oC Length: l = 29 m Temperature: T1 = 29 oC Change in length: Δl = -7 cm (-0.07 m) Step 2: Write down what you don't know in symbolic form: Temperature: T2 = ? oC Step 3: Find an equation that contains what you know and what you don't know: Δl = αlΔT = αl(T2 - T1) Step 4: Solve the equation for what you don't know: Δl = αl(T2 - T1); divide both sides by αl Δl/ αl = (αl/ αl )(T2 - T1) = T2 - T1; add T1 to both sides Δl/αl + T1 = T2 - T1 + T1 = T2 Δl/ αl + T1 = T2 Step 5: Plug in (substitute) what you know and you will find out what you don't know: Δl/ αl + T1 = T2 = (-0.07 m)/( 25 x 10-6 /oC x 29 m) + 29 oC = -96.551 oC + 29 oC = -67.551 oC = -67.6 oC rounded off.

Send your message to us

Skid Aluminum Coil for Coated Aluminum Honeycomb Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords