Dibond Silver Aluminum Sheets - Cold Rolling 1100 3003 Aluminum Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Cold Rolling 1100 3003 Aluminum Tread Plate Description:

Aluminum alloys 1xxx series, 2xxx series, 3xxx series, 5xxx series, 6xxx series and 8xxx series. They are available in various sizes with thicknesses from 0.1mm to 500mm, widths from 10mm to 3, 000mm andlengths below 12m. 1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. 3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment

2.Main Features of Cold Rolling 1100 3003 Aluminum Tread Plate :

Low density, light in weight

Anti-corrosion

Strong

Malleable

Naturally good looking

Recyclable

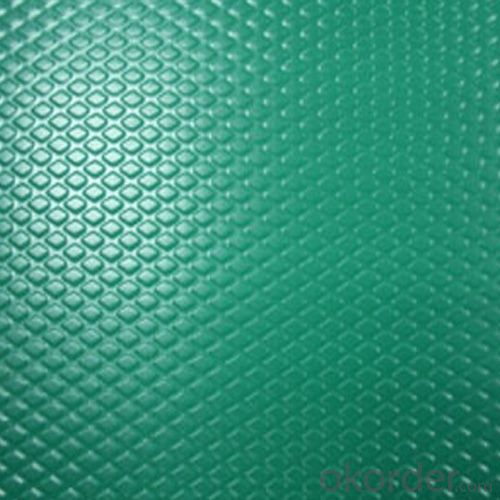

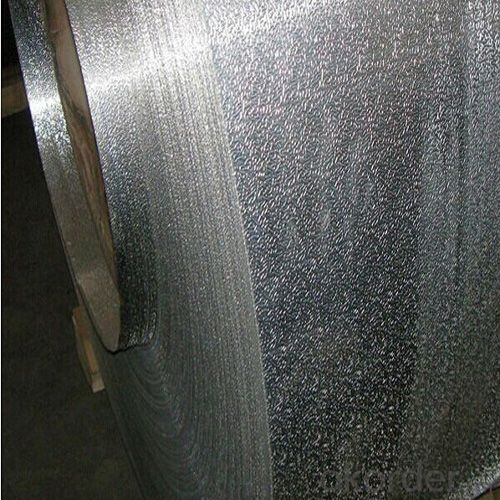

3.Cold Rolling 1100 3003 Aluminum Tread Plate Images:

4. Cold Rolling 1100 3003 Aluminum Tread Plate Specification:

Embossing Aluminum Tread Sheet | |

Alloy | 1100,1060, 3003, 5005 5052 |

Temper | H14,H18,H24,H32 |

Thickness (mm) | 1.5mm to 6mm |

Width (mm) | Up to 1500mm |

Length (mm) | Up to 6000mm |

Standard | EN standard ASTM standard |

MOQ | 5ton |

Application | 1)Decorated inside and outside the car /building frame, windows, doors, ceiling, decorating panel and curtain wall 2)Household appliances: refrigerators, microwave ovens, audio equipment, etc. |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Yes, aluminum sheets are suitable for manufacturing electronic enclosures. Aluminum is lightweight yet sturdy, providing excellent protection for electronic components. It is also corrosion-resistant, making it suitable for various environments. Additionally, aluminum is a good conductor of heat, allowing for effective thermal management in electronic enclosures.

- Q: Are aluminum sheets suitable for electrical enclosures?

- Yes, aluminum sheets are suitable for electrical enclosures. Aluminum is a lightweight and durable material that offers excellent electrical conductivity and corrosion resistance, making it an ideal choice for protecting electrical components. Additionally, aluminum's thermal conductivity helps dissipate heat generated by the enclosed equipment, ensuring proper functioning and longevity.

- Q: what's the temperature tolerance of aluminum sheets?

- aluminum is a kind of silver white metal,melting point:660.4℃, boiling point: 2467℃,density: 2.70 g/cm?,very light, about 1/4 of iron's density.it has low hardness and good ductility, which makes it suitable for being pulled into threadlets or pressed into aluminum foils, and the later is usually used for packaging candy and cigarette. it has good electrical and temperature conductivity. it's used for the manufacture of electric wire and cable in electric power industry, and for the manufacture of cooker in daily life bined with the magnesium , copper,zinc,tin,manganese,chromium,zirconium,silicon and other elments,it can formulate various alloys that is broadly used for the manufacture of airplane,car,ship, materials of daily living equipment and the doors and windows of construction industry.aluminum is one of the best reflectors of heat and light, so it is used as thermal insulation material and the manufacture of reflecting mirror in the reflecting telescope.

- Q: Are 101 aluminum sheets suitable for chemical transfer piping?

- No, 101 aluminum sheets are not suitable for chemical transfer piping. Aluminum is generally not recommended for handling certain chemicals due to its reactivity and potential for corrosion. It is more commonly used in industries that require lightweight materials and good thermal conductivity, such as aerospace or construction. For chemical transfer piping, it is advisable to use materials that are resistant to corrosion and can withstand the specific chemicals being transported, such as stainless steel, PVC, or high-density polyethylene (HDPE).

- Q: Can the aluminum sheets be used for manufacturing chemical reactors?

- Indeed, chemical reactors can be manufactured using aluminum sheets. Renowned for its exemplary resistance to corrosion and remarkable thermal conductivity, aluminum is a suitable option for diverse industrial purposes, including the production of chemical reactors. Moreover, aluminum possesses the advantage of being lightweight and malleable, facilitating the creation of reactors with varying sizes and configurations. Nevertheless, it is crucial to acknowledge that selecting the appropriate materials for chemical reactors hinges on the particular demands of the process and the chemicals employed. In certain instances, environments characterized by corrosiveness or high temperatures may necessitate the utilization of more specialized materials.

- Q: Can aluminum sheet be used for electrical enclosures?

- Yes, aluminum sheet can be used for electrical enclosures. Aluminum is a commonly used material in the electrical industry due to its excellent conductivity, corrosion resistance, and lightweight properties. It provides good shielding against electromagnetic interference and is easy to fabricate into various shapes and sizes for enclosures.

- Q: If something is wrong, what kind of glue can be used for bonding the stainless steel sheet and aluminum sheet? The area may be very big. What are some common or good glue to buy?

- Is the whole surface covered with glue or covered with four sides?What are you asking for?This kind of structure can use more glue,Acrylic structural adhesive, epoxy structural adhesive, silicone structural adhesiveNeed to understand glue, we can communicate,

- Q: you can turn in aluminum cans for cash some are called golden goats

- Aluminum okorder

- Q: What are the different methods of cutting aluminum sheet?

- Some of the different methods of cutting aluminum sheet include using shears, bandsaws, jigsaws, circular saws, laser cutting, and waterjet cutting.

- Q: i have a aluminum bicycle the first time i painted it i painted over the original paint(didnt know any better). The second time i sanded it down with some paint left on it. Now this time im sanding it but im using 60grit it looks good to me is 60 grit to much.

- You screwed up. 60 grit should NEVER come in contact with aluminum... those scratches will never come out. NEVER have an aluminum frame sandblasted. You'll need to have it soda blasted or walnut shell blasted. You should be using 220 grit ALUMINUM OXIDE paper- it is white in color. My bet is that you are using garnet- the brown stuff, or maybe coated paper. You MUST use aluminum oxide. I have answered the question to paint a bike a hundred times. Just click on Discover and type in the words paint a bike without quotes. Theres your answer.

Send your message to us

Dibond Silver Aluminum Sheets - Cold Rolling 1100 3003 Aluminum Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords